Dilution water hydraulic type flow box dilution water valve control device and method

A hydraulic headbox and dilution water technology, applied in textile and papermaking, papermaking, paper machine wet end, etc., can solve the problems of system collapse, system disorder, slow processing speed, etc. The effect of strong performance and improved reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

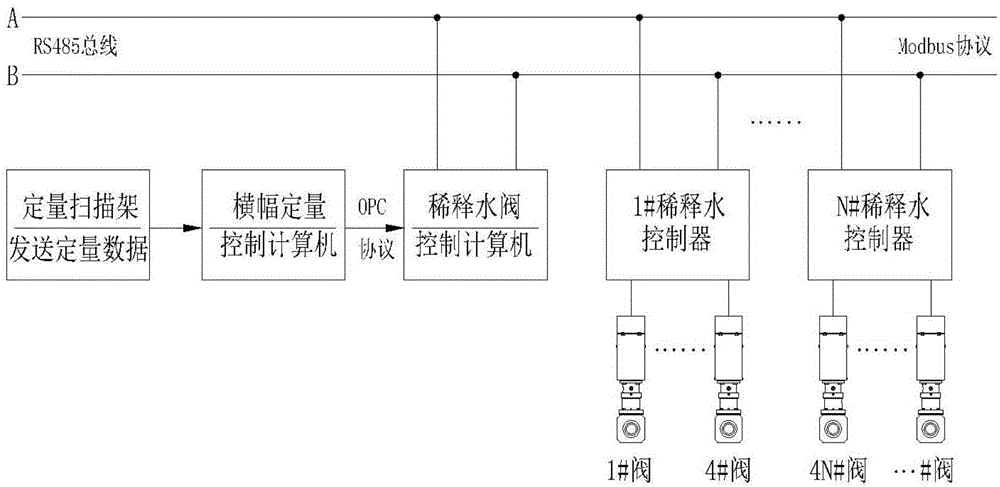

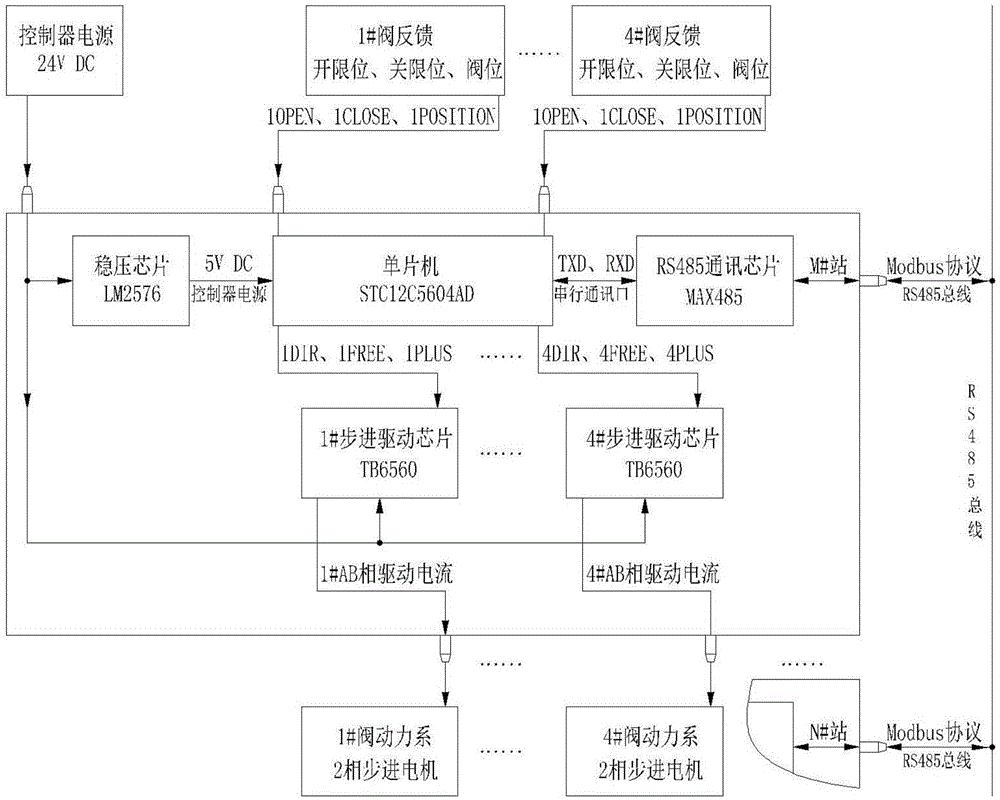

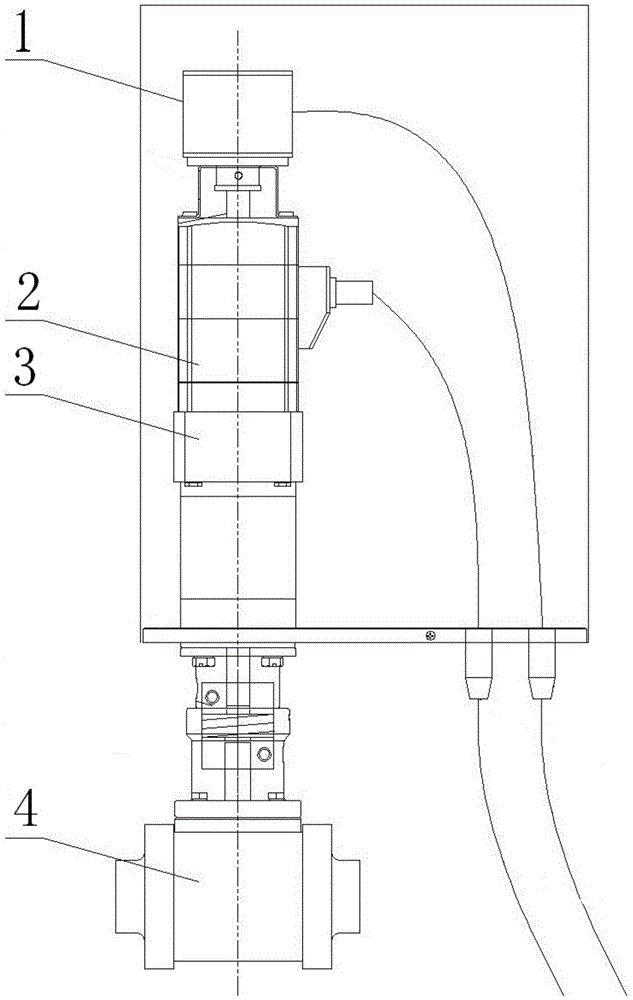

[0025] see figure 1, a dilution water hydraulic headbox dilution water valve control device, including a banner quantitative control computer, a quantitative scanning frame arranged in the drying section of a paper machine, a dilution water valve control computer, and several dilution water controllers (the numbers are respectively 1# Dilution water controller, ..., N# dilution water controller) and up to four dilution water valves connected to one dilution water controller (the numbers are respectively 1# dilution water valve, 2# dilution water valve, ...), banner quantitative The control computer obtains the quantitative data of each area of the paper from the quantitative scanning rack. The OPC communication protocol sends the quantitative data to the control computer of the dilution water valve. The dilution water controller has different communication address nu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com