Device for analyzing stability of embankment under effect of earthquake load and manufacturing method of device

A seismic load and stability technology, applied in the direction of measuring devices, machine/structural component testing, vibration testing, etc., to achieve high measurement accuracy, reduce box weight, and reduce weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

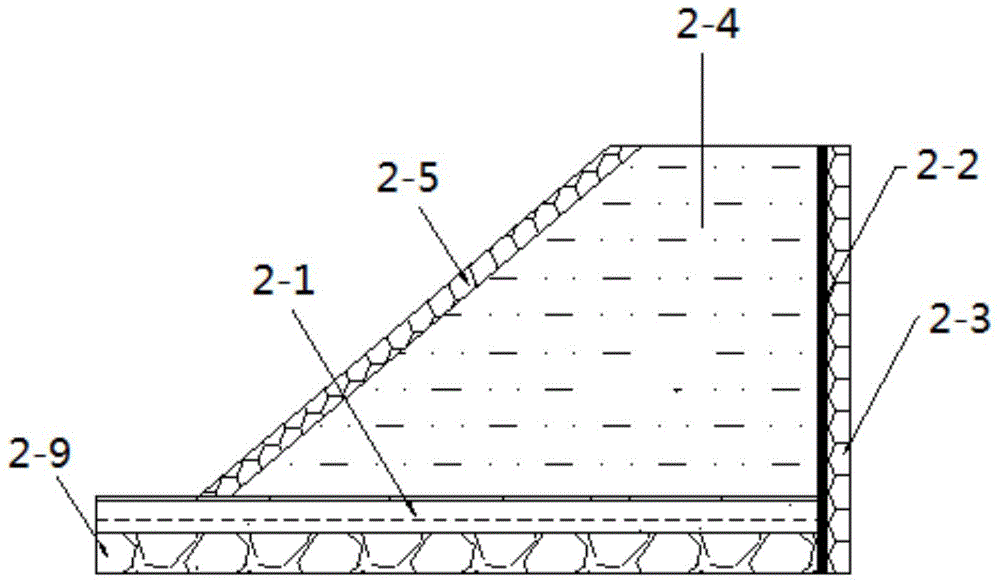

[0046] Step 1: First make a sandbox 1, one group of facing surfaces of the sandbox 1 is plexiglass 1-3, and the other surface is a wooden board 1-4, secondly, select sand samples from the aeolian sand area and lay them on the bottom of the sandbox first Gravel layer 2-9, lay sand layer 2-1 on the gravel layer 2-9, and then adopt layered compaction method to lay aeolian 2-4 sand layer by layer, and aeolian sand 2-4 Tamping, control the degree of compaction and water content, use L-shaped baffles 2-10 to assist slope compaction, first make the model into a ladder shape, and then use cutting to cutting to form, the slope with wrapping layer is made using two The method of filling and cutting is formed. After the embankment is filled for the first time, the excess sand is cut off, and the edge wrapping material is added for filling and compaction for the second time, and the excess edge wrapping layer material is cut off. slope forming;

[0047] Step 2: set waterproof sponge 2-3 ...

Embodiment 2

[0053] Step 1: First make a sandbox 1, one group of facing surfaces of the sandbox 1 is plexiglass 1-3, and the other surface is a wooden board 1-4, secondly, select sand samples from the aeolian sand area and lay them on the bottom of the sandbox first Gravel layer 2-9, lay sand layer 2-1 on the gravel layer 2-9, and then adopt layered compaction method to lay aeolian 2-4 sand layer by layer, and aeolian sand 2-4 Tamping, controlling the degree of compaction and water content;

[0054] Step 2: set waterproof sponge 2-3 on the side of plank 1-4, the surface layer of waterproof sponge 2-3 is covered with plastic film 2-2, and set scale 5 outside plexiglass 1-3 and plank 1-4;

[0055] Step 3: Mark the filling thickness of each layer and the outline of the slope slope on the plexiglass 1-3, and fill each layer of filling materials in layers according to the drawn lines, with clay-bound edges Draw the contour lines of the aeolian sand and the edged clay on the side slope, and fil...

Embodiment 3

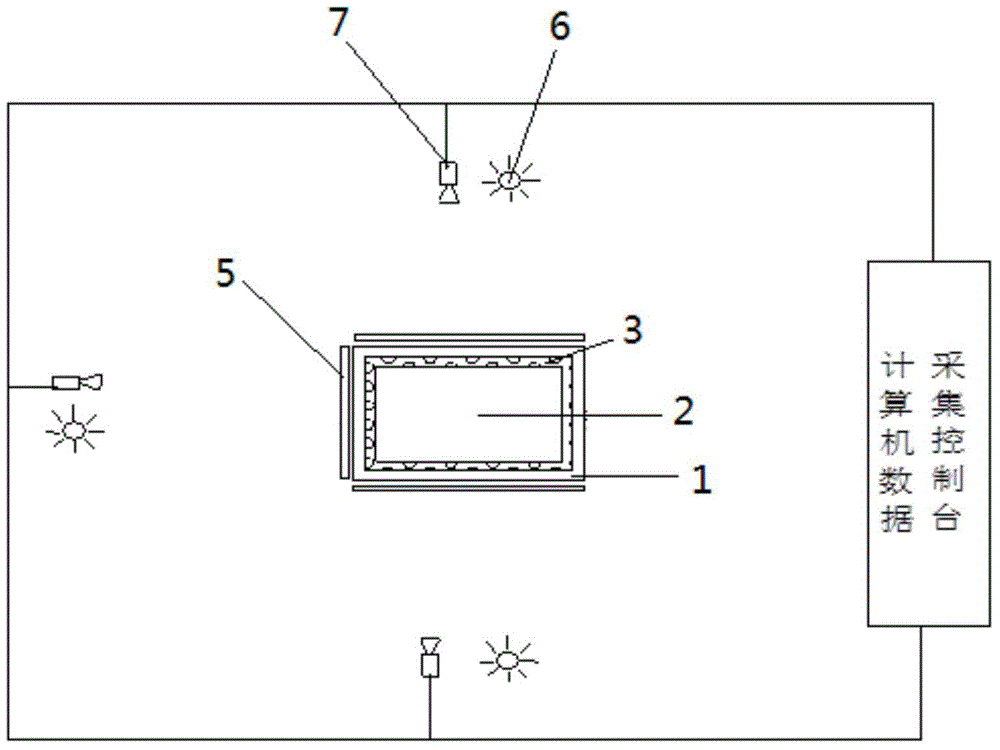

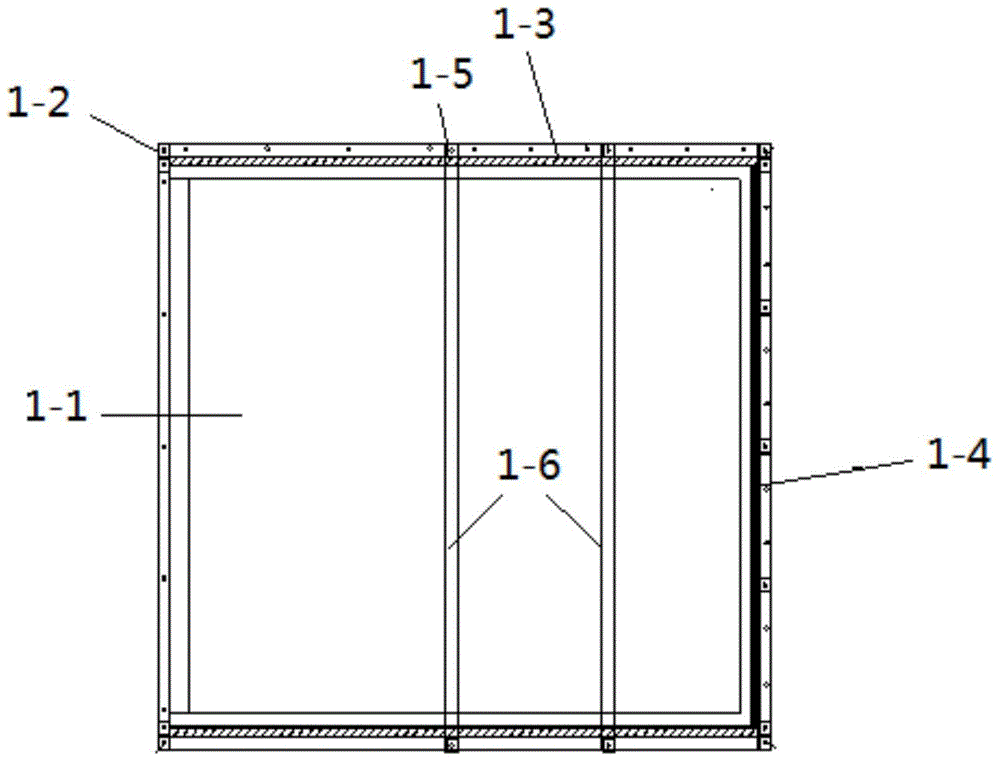

[0060] 1. Design and production of model box

[0061] (1) This test uses a rigid model box with three sides closed and one side open. The size of the model box is about 1960*1700*800 (length*width*height). The frame is made of 40*3 equilateral angle steel, and 20mm thick Plexiglass, and a 20mm thick composite wood board is installed on the other side; 100*100*3 (length*width*height) type H steel is used as the base, and 2mm thick steel plates are laid on the base, and small steel plates are welded vertically and unevenly on the steel plate The purpose is to increase the friction between the embankment model and the box base; the model box base and the vibration table are connected by bolts, and the base H-shaped steel is cut with openings for fixing bolts. In order to prevent the frame from deforming during hoisting, transportation and vibration of the model box, reinforcing ribs are added on the upper part of the model box and on the wall of the wooden box, and the reinforcin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com