Piezoelectric type energy harvester

An energy harvester, piezoelectric technology, applied in the field of mechanical vibration energy recovery device, to achieve the effect of easy replacement, improve piezoelectric conversion efficiency, and reduce pulsation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

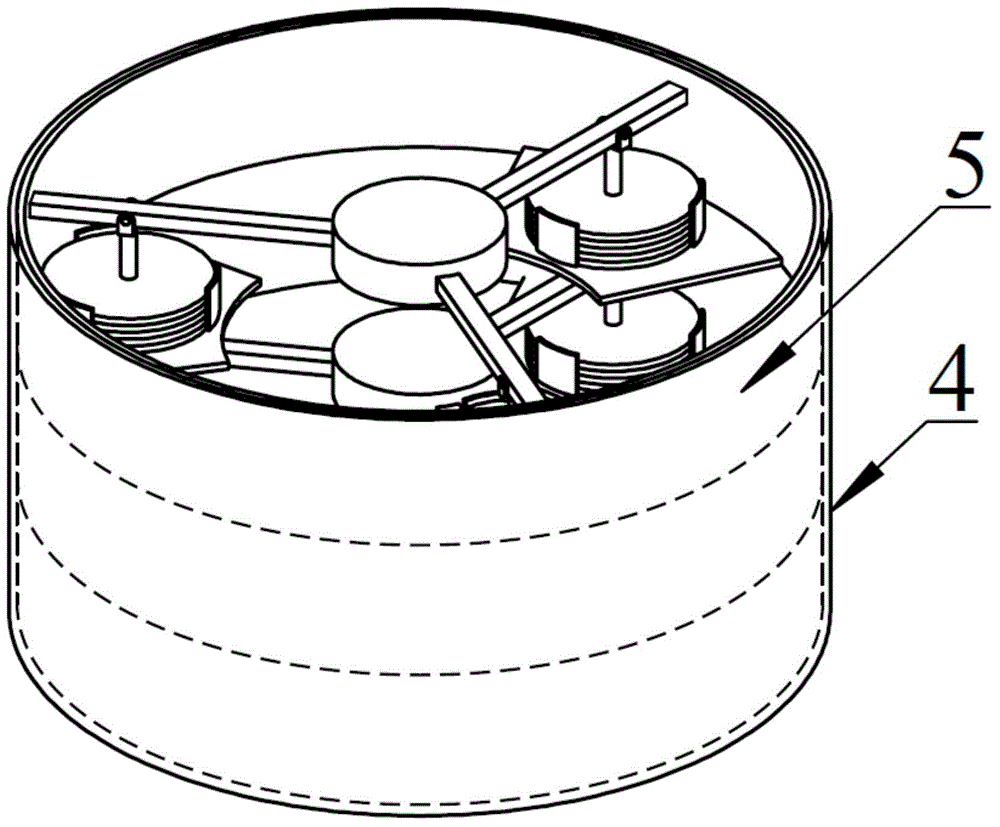

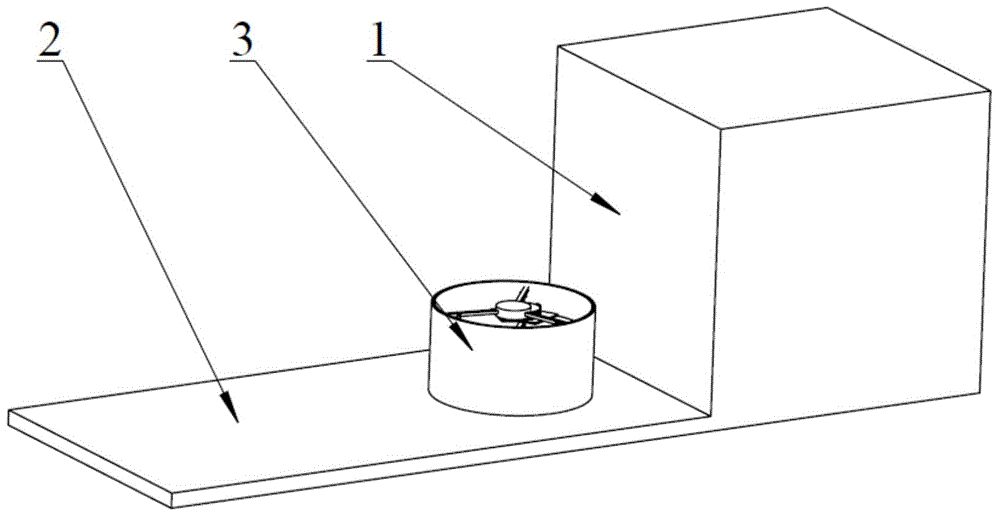

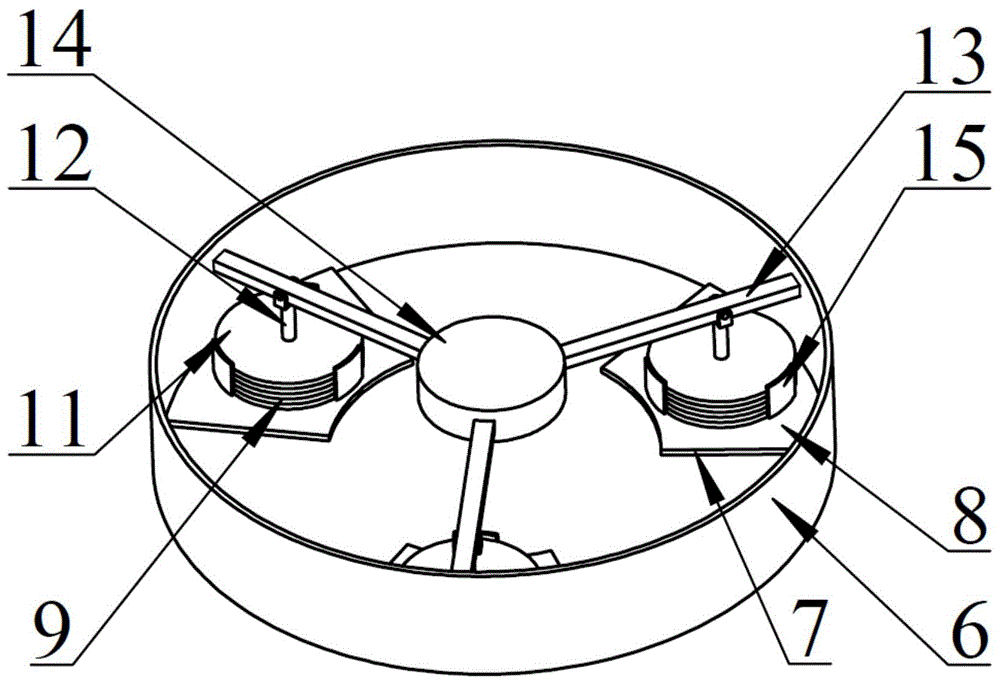

[0018] Such as Figure 1~5 As shown, the improved piezoelectric energy harvester of the present invention includes a barrel-shaped base 4 for accommodating the piezoelectric energy harvester 3 and fixing it on the base 2 of the diesel engine 1 . The barrel-shaped base 4 is provided with a piezoelectric unit 5, the piezoelectric unit 5 includes an annular shell 6, three stages 7 are evenly arranged on the inner surface of the annular shell 6, and the supporting surface 8 of each stage 7 on the same level. Each stage 7 is respectively provided with a piezoelectric ceramic stack 9 and a limit baffle 15 for limiting the position of the piezoelectric ceramic stack 9. The limit baffle 15 surrounds the periphery of the piezoelectric ceramic stack 9, and its inner surface is tight. Paste the side of piezoelectric ceramic stack 9. The piezo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com