Fish raft net cage prepared from steel material

A net cage and fishing raft technology, which is applied in the fields of application, fish farming, climate change adaptation, etc., can solve the problems of not being resistant to wind and waves, not being strong enough, and the net cage is easily corroded by seawater, etc., to improve safety and ensure safety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

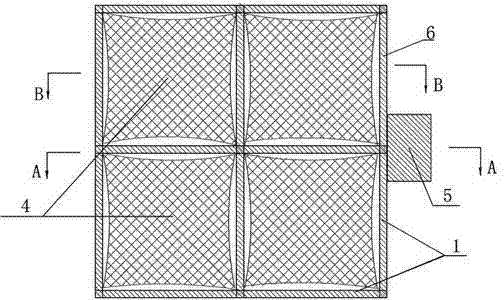

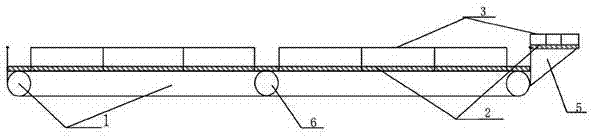

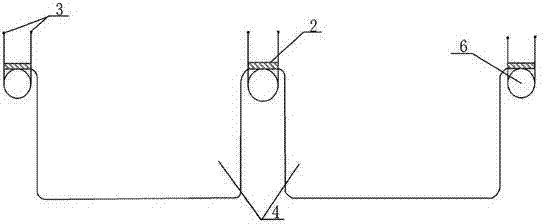

[0017] The present invention will be further described below in conjunction with accompanying drawing, a kind of fishing raft cage made of steel, such as figure 1 as shown, figure 1 What is shown is only a top view of one unit of the present invention, and the present invention can be combined and connected by multiple units. The present invention comprises a floating body steel frame 1, a steel pedal 2, a steel frame guardrail 3, and a cage 4 connected to the inner side of the floating body steel frame 1. The floating body steel frame 1 of a unit is in the shape of a square, including 4 network ports, each network port has a specification of 8m×8m, and the floating body steel frame 1 has an inner diameter of 245-610mm and a wall thickness of 1-10mm. Made of seamless steel pipe 6, the bending part of the floating body steel frame 1 is connected with an elbow, and the connection without bending part is to cut the gaps of the steel pipes that need to be connected and then weld ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com