A kind of processing method of alpine jade bud tea

A processing method and technology of jade bud tea are applied in the processing field of tea leaves to achieve the effects of increasing content, strong and mellow aroma, and pure aroma

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

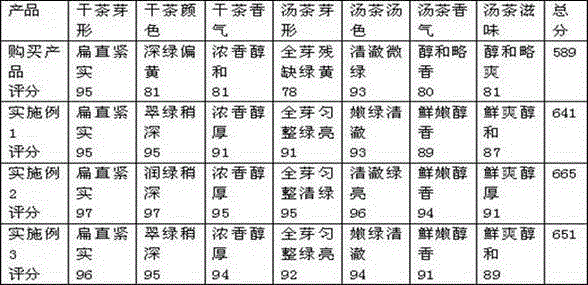

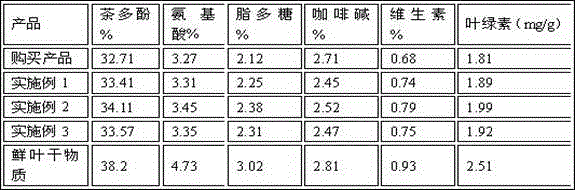

Embodiment 1

[0019] On March 8, 2014, from 9:00 to 11:30 in the morning, the single bud tip of the Bayu special morning tea planted in Xiaopo Village, Zhongtang Township, Qianjiang District, Wuling Mountain was picked. After harvesting, put the bud tips in a bamboo sieve and spread them flat, with a thickness of 2-3cm. Then place the bamboo sieve compartment in a well-ventilated room, start the breeze around the room, and keep the indoor temperature at 13°C. Let stand for 5 hours. Then microwave-steam linkage is used to fix the greens, that is, the output power of the microwave killing machine is determined to be 10kW, the microwave frequency is determined to be 2400MHz, and the greening is completed for 70 seconds. The temperature is controlled at 80°C, and the shoots are taken out when the moisture content of the bud tips is 55%. Then quickly put the finished bud tips into the cooling and dampening machine, set the temperature in the cooling and dampening machine to 5°C, rehydrate for 2...

Embodiment 2

[0025] On March 18, 2014, from 9:00 to 11:30 in the morning, the single bud tip of the Bayu special early tea variety tea tree planted in Xiaping Village, Xiaonanhai Town, Qianjiang District, Wuling Mountain was picked. After harvesting, put the bud tips in a bamboo sieve and spread them flat, with a thickness of 2-3cm, and then place the bamboo sieve compartment in a well-ventilated room, start the breeze around the room, and keep the indoor temperature below 15°C time, spread out for 5.5 hours. Then microwave-steam linkage is used to fix the greens, that is, the output power of the microwave killing machine is determined to be 10kW, the microwave frequency is determined to be 2450MHz, and the greening is completed for 60 seconds. The temperature is controlled at 85°C, and the shoots are taken out when the moisture content of the bud tips is 57%. Then quickly put the finished bud tips into the cooling and dampening machine, set the temperature in the cooling and dampening ma...

Embodiment 3

[0031] On March 30, 2014, from 9:00 to 11:30 in the morning, we picked the single bud tip of the Bayu special morning tea planted in Dengqian Village, Shanling Township, Qianjiang District, Wuling Mountain. After harvesting, put the bud tips in a bamboo sieve and spread them flat, with a thickness of 2-3cm, and then place the bamboo sieve compartment in a well-ventilated room, start the breeze around the room, and keep the indoor temperature below 17°C Time, spread out for 6 hours. Then adopt microwave-steam linkage to fix green, be about to determine the output power of microwave clear green machine as 10kW, microwave frequency is determined as 2500MHz, clear blue green for 50 seconds, put into steam clear green machine immediately when leaf temperature rises to 85 ℃, clear green time 6 minutes, leaves The temperature is controlled at 90°C, and the shoots are taken out when the moisture content of the bud tips is 59%. Then quickly put the finished bud tip into the cooling an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com