Intelligent transfer trolley for sample collection and preparation

An intelligent, sample technology, applied in the fields of motor vehicles, transportation and packaging, non-electric variable control, etc., can solve the problems of low degree of transfer automation, high production and maintenance costs, low work efficiency, etc., to achieve automatic sample preparation and transfer. Excellent safety and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be described in further detail below in conjunction with specific embodiments and accompanying drawings.

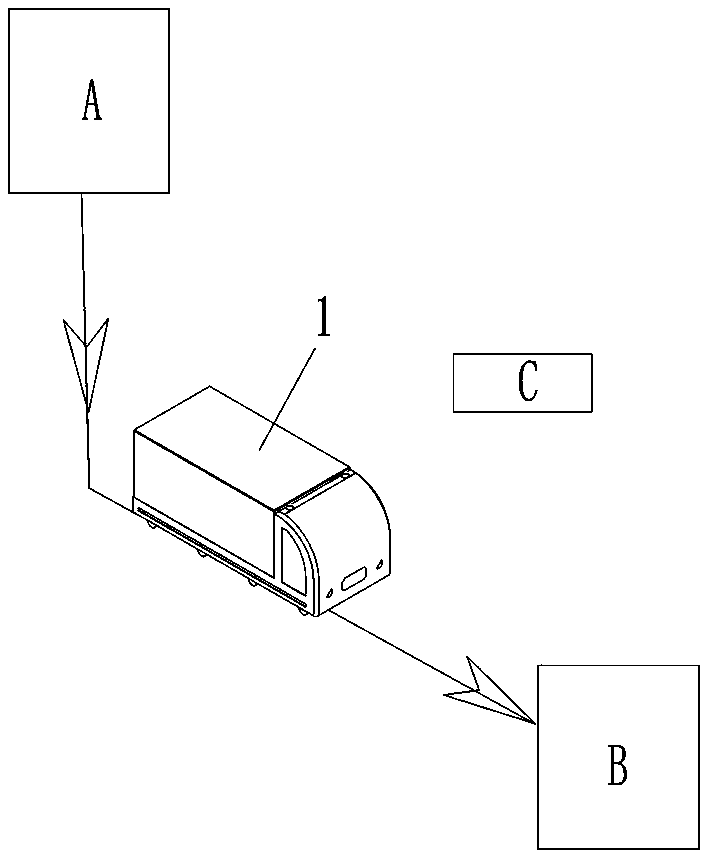

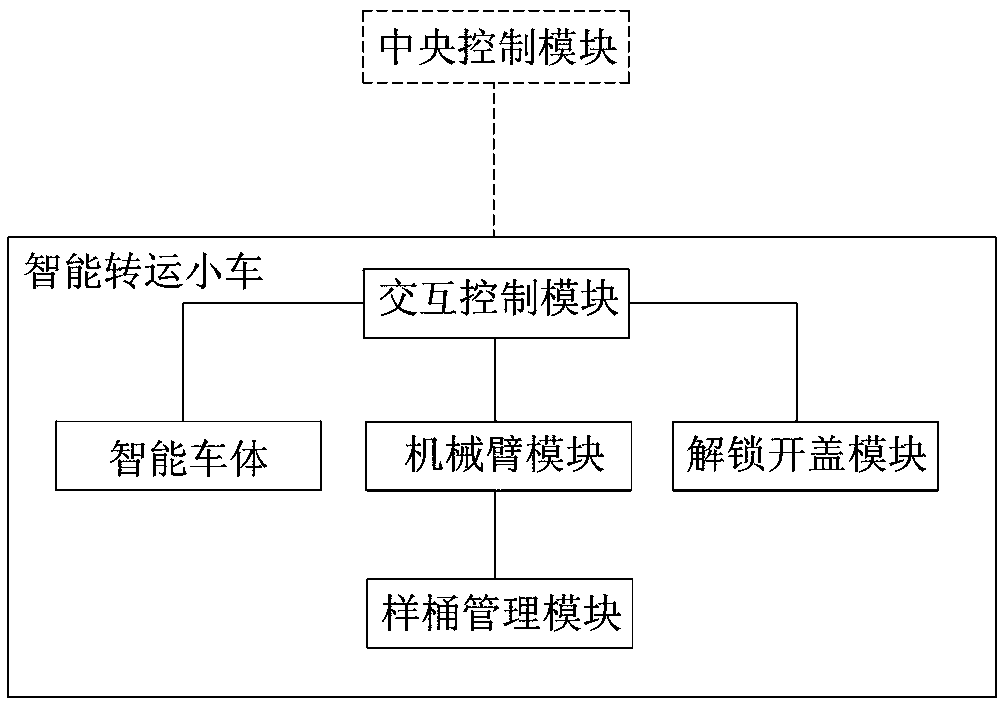

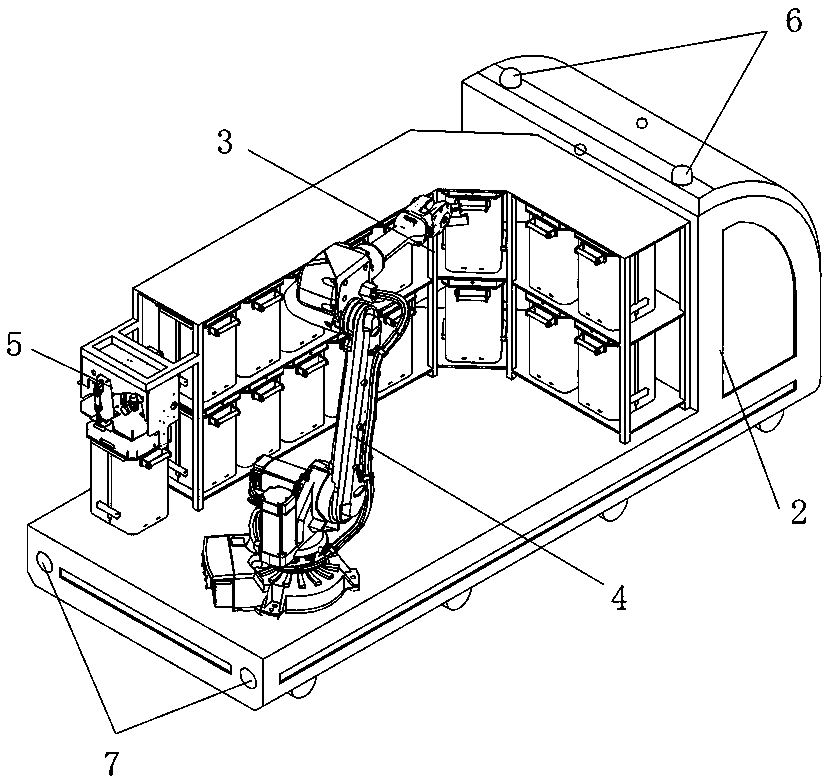

[0043] Such as Figure 1 to Figure 6 As shown, the present invention provides an intelligent transfer trolley for sample collection and processing, including an intelligent vehicle body 1, and the length of the intelligent vehicle body 1 is not less than 0.5 meters. The intelligent car body 1 is provided with an interactive control module 2 and a mechanical arm module 4; the interactive control module 2 communicates interactively with the central control module of the sample collection and processing system, and is used to control the movement of the intelligent car body 1 in the sample collection and processing system; the interactive control The module 2 communicates with the robotic arm module 4, and is used to control the robotic arm module 4 to clamp the sampling bucket to move between the smart car body 1 and the outside world to re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com