Flow-isolating and energy-saving rice mill and rice milling method

A rice milling machine and rice machine technology, applied in energy saving measures, agricultural machinery and equipment, grain processing and other directions, can solve the problems of high pressure, power consumption and energy consumption in the whitening chamber, so as to improve production efficiency, reduce power consumption, Rice milling effect is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

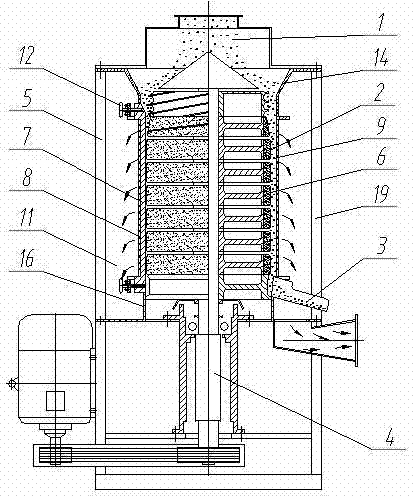

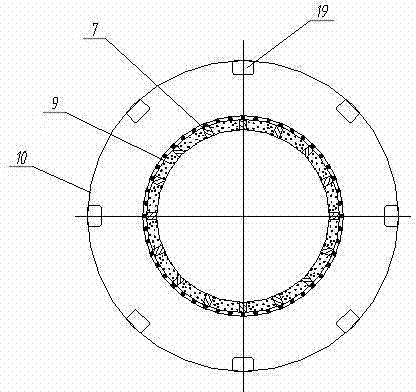

[0028] An energy-saving rice milling machine with cut-off flow, its composition includes: feeding device 1, whitening chamber 2, discharge device 3, transmission device 4 and frame 5, and described whitening chamber includes a set of rolls 6, A rice milling room 9 composed of a spacer body 7 and a rice sieve 8, the distance between the spacer body and the roller is less than 2 millimeters, and the rice sieve is installed on the outside of the spacer body, and the rice There is a negative pressure space 11 between the outside of the screen and the casing 10, and the negative pressure space is connected with a suction fan.

Embodiment 2

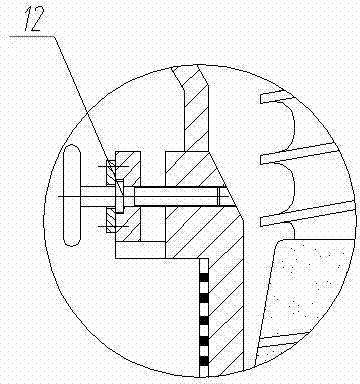

[0030] In the energy-saving rice mill with cut-off flow described in Embodiment 1, the cut-off body has a gap adjustment mechanism 12, and the number of cut-off bodies is 4-40.

Embodiment 3

[0032] In the flow-blocking energy-saving rice milling machine described in embodiment 1 or 2, the upper and lower ends of the spacer body have sieve positioning grooves, and the upper end positioning groove 13 is located on the same plane as the lower surface of the upper round body 14 of the frame. The lower end locating groove 15 and the lower circular body upper surface of the frame are located on the same plane, and the rice sieve has a sieve hole 17, the width of the sieve hole is 0.6-1.8 millimeters, and the length of the sieve hole is 8 mm. -20 mm, the sieve holes are arranged obliquely.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com