Female die wedge block locking mechanism of automatic forging press

A technology of locking mechanism and forging press, which is applied in forging/pressing/hammering machinery, forging/pressing/hammer device, manufacturing tools, etc. It can solve the problems of hindering the movement of the manipulator, damaging the cutting knife, hitting the female mold, etc. , to achieve the effect of good promotion value, low pressure and large locking force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

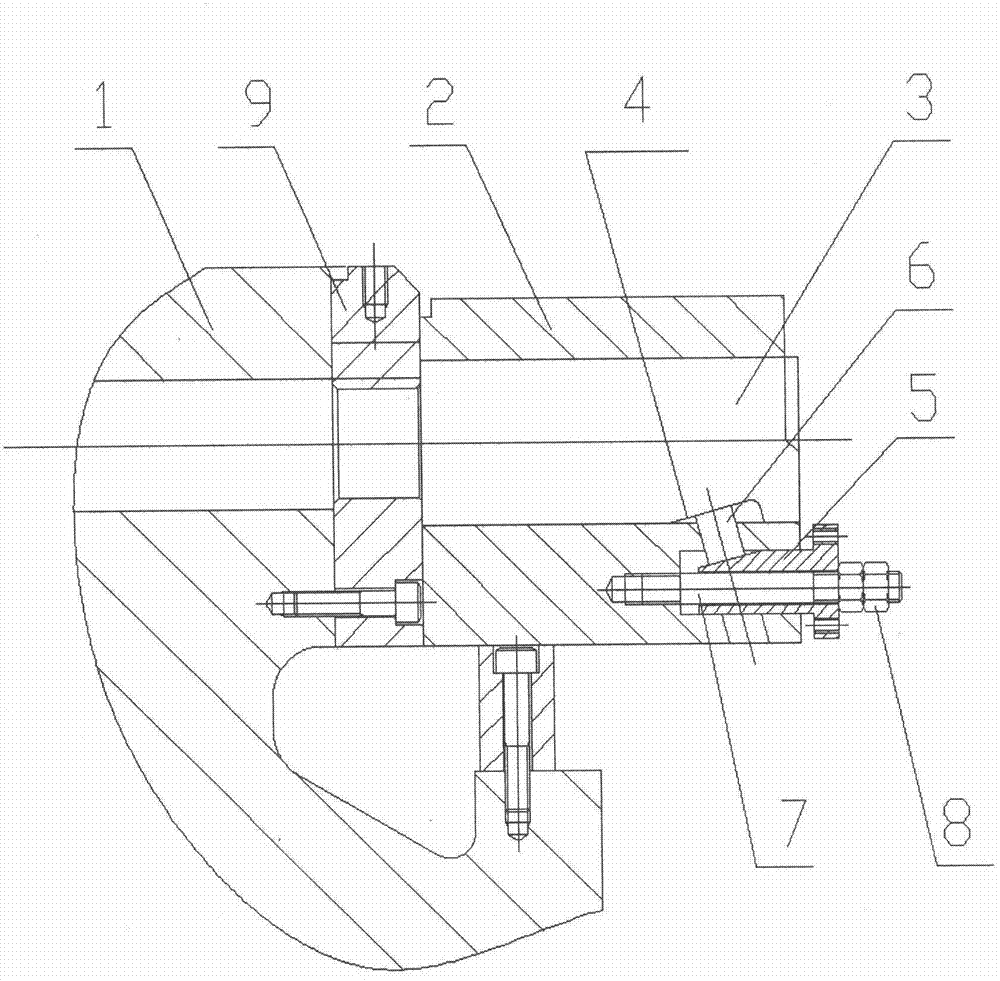

[0011] Such as figure 1 As shown, the present invention provides a locking mechanism for a female mold wedge of an automatic forging press, comprising a frame 1, a female mold seat 2 is installed on the frame, and a female mold 3 is installed in the female mold seat; the female mold and the female mold The connecting surface of the seat is the female mold locking inclined plane 4; the female mold locking sleeve 5 and the female mold locking block 6 are installed on the female mold seat, and the female mold locking sleeve is inserted into the female mold perpendicular to the female mold locking block In the locking block, the contact surface of the female mold locking sleeve and the female mold locking block is a locking slope that cooperates with each other, the top of the female mold locking block is pressed against the female mold locking slope, and the stud bolt 7 passes through the female The mold locking sleeve is connected with the female mold base. A nut 8 is installed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com