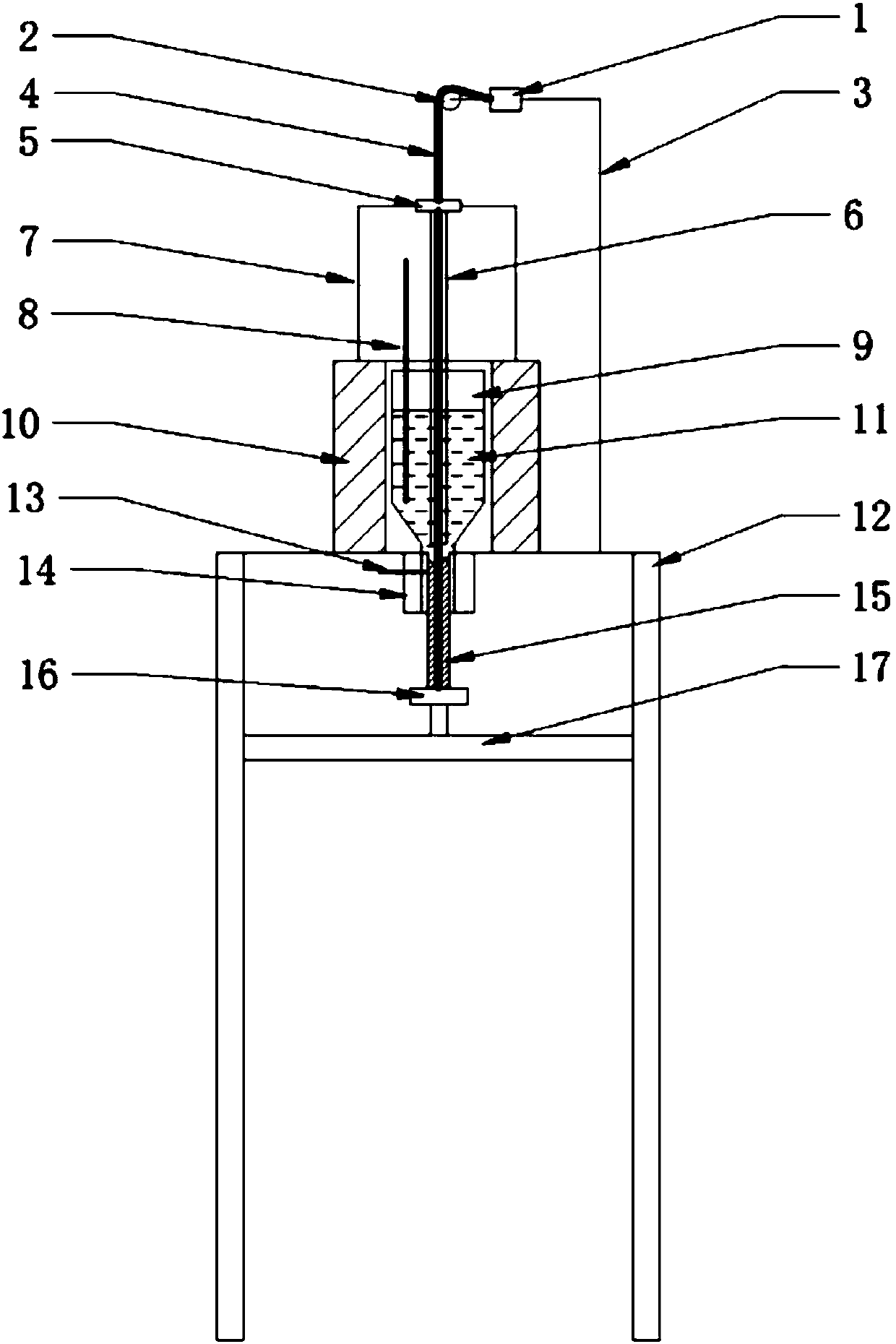

Long carbon fiber and metal composite continuous casting machine and process

A long carbon fiber and metal composite technology, applied in the field of metal materials, can solve the problems of poor performance of long carbon fibers and metal composite materials, and achieve the effects of low cost, simple equipment structure and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0086] Casting of aluminum and long carbon fiber layered composites

[0087] The aluminum and long carbon fiber layered composite material is a rod with a diameter of 12mm, and the diameter of the long carbon fiber bundle at the core is 2mm; the heating method of the metal temperature-controlled furnace adopts resistance heating; the temperature of the metal temperature-controlled furnace is controlled within the range of the metal solidification temperature of 100°C; Graphite material; the crystallizer adopts water-cooled graphite crystallizer, adopts circulating water cooling method; carbon fiber pre-tightening force is controlled at 0-20N; the test results show that the interface of the sample is dense and neat, and the mechanical properties of the test rod made of pure aluminum are greater promote.

Embodiment 2

[0089] Copper and Long Carbon Fiber Laminated Composite Casting Forming

[0090] The copper and long carbon fiber layered composite material is a pipe with an outer diameter of 20mm and an inner diameter of 14mm, and the diameter of the long carbon fiber bundle on the pipe wall is 1mm; the heating method of the metal temperature control furnace adopts electromagnetic induction heating; the temperature of the metal temperature control furnace is controlled at the metal solidification temperature point 100 ℃ The crucible is made of graphite; the crystallizer is water-cooled copper crystallizer, and the cooling method is adopted by circulating water; the carbon fiber preload is controlled at 0-20N; The performance has been greatly improved.

Embodiment 3

[0092] Casting Forming of Lead and Long Carbon Fiber Laminated Composite

[0093] The lead and long carbon fiber layered composite material is a rod with a diameter of 15mm, and the diameter of the long carbon fiber bundle at the core is 1mm; the heating method of the metal temperature-controlled furnace adopts resistance heating; the temperature of the metal temperature-controlled furnace is controlled within the range of the metal solidification temperature of 100°C; 45 steel; the carbon fiber preload is controlled at 0-20N; blowing cooling is adopted; the test results show that the interface of the sample is dense and neat, and the mechanical properties of the test bar made of pure lead are greatly improved.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com