FOCKE350 packing machine card paper propeller sliding device

A sliding device, machine jamming technology, applied in the direction of packaging machines, packaging, packaging cigarettes, etc., can solve the problems of affecting the effective operation rate of equipment, long shutdown and replacement maintenance time, wear and tear, etc., so as to reduce the maintenance workload and maintenance costs , The time required for replacement and maintenance is short, and the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

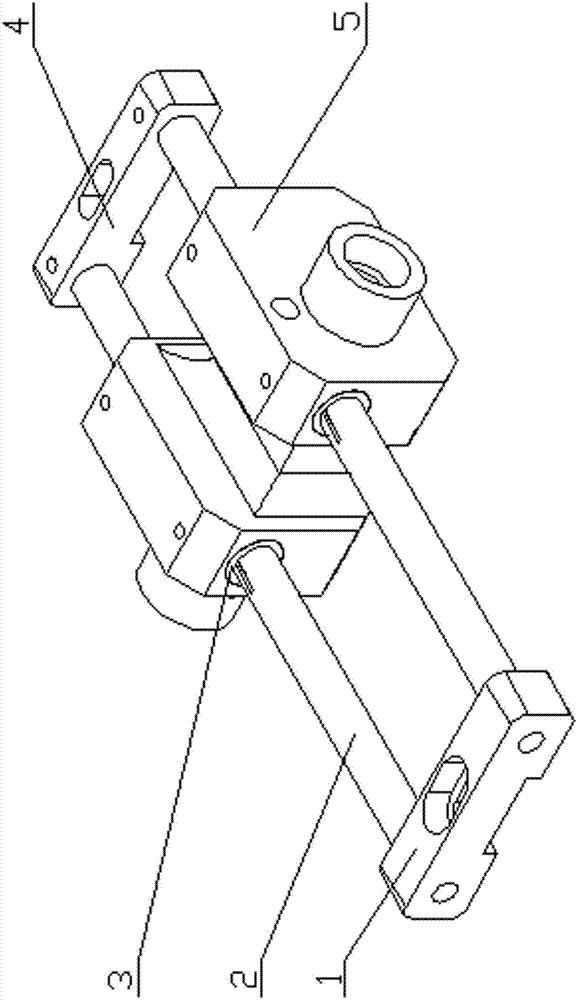

[0029] 1. First survey and map out the bracket of the block before the transformation, and design the shaft supports at both ends to determine the position of the shaft installation hole.

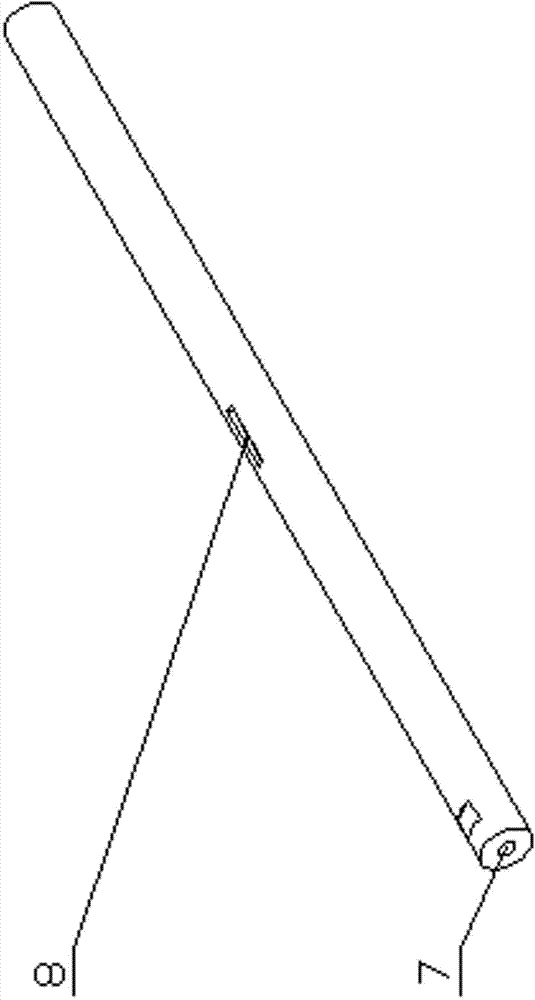

[0030] 2. Survey and map the position of the installation shaft on the trolley bracket, and redesign and manufacture the trolley support 1 under the premise of ensuring that the function of the original mechanism remains unchanged.

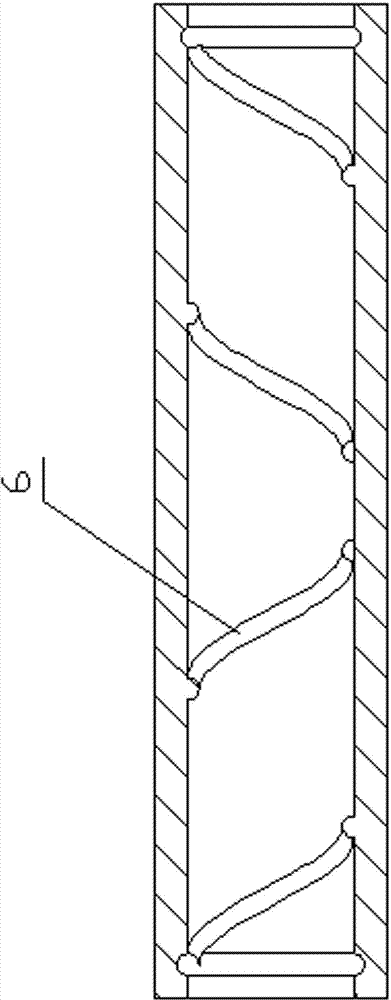

[0031] 3. In order to ensure that the pulley is fully lubricated when it moves on the shaft, the central lubricating oil supply pipeline of the original machine is adopted, the lubricating oil channel is designed on the shaft, and the helical line storage lubricating oil channel is designed in the Boss sleeve 3.

[0032] 4. The distance between the installation hole of shaft 2 and the installation hole of Boss sleeve 3 is 26mm, because the hole and the installation hole of Boss sleeve 3 form a cross-shaped intersection. The shaft installation hole is a step hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com