Hydrogenation method for preparing hydrogen peroxide by adopting anthraquinone process

A technology of hydrogen peroxide and anthraquinone method, applied in the field of hydrogenation, can solve the problems of poor product quality, large investment, high production consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

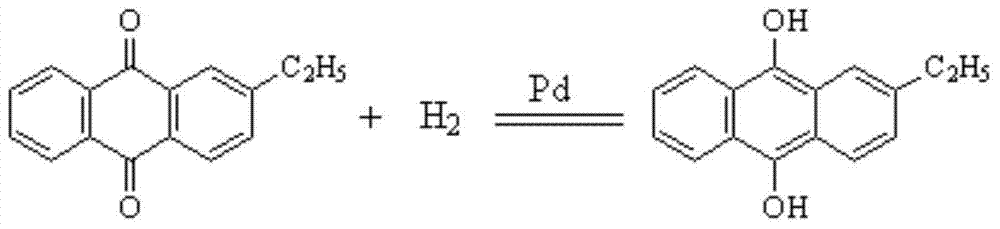

Image

Examples

Embodiment Construction

[0017] According to the characteristics of hydrogen peroxide technology, raw materials, reaction and production control, the present invention develops an anthraquinone hydrogen peroxide production hydrogenation partial fluidized bed hydrogenation process. The present invention will be further described below in conjunction with the examples, and the examples are only for explanation and not intended to limit the protection scope of the present invention.

[0018] The raw materials of this embodiment are mainly divided into three parts: a. hydrogen-containing gas, b. anthraquinone working fluid, and c. solid particles containing catalyst, wherein:

[0019] a. Hydrogen-containing gas. The hydrogen needed to generate hydroanthraquinone is mixed with the cycle gas and nitrogen from the hydrogen cycle compressor before entering the fluidized bed hydrogenation reactor, and the mixed hydrogen accounts for 40-100% of the volume of the hydrogen-containing gas. The feed hydrogen gas e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com