Electrochemical oxidation device for advanced treatment of wastewater produced by amidoximation

A technology for production wastewater and advanced treatment, applied in water/sewage treatment, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve the problem of many by-products and intermediate products, long production process, and large amount of recycled materials And other problems, to achieve the effect of not easy to react, long service life, high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

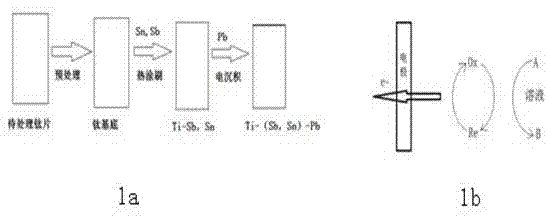

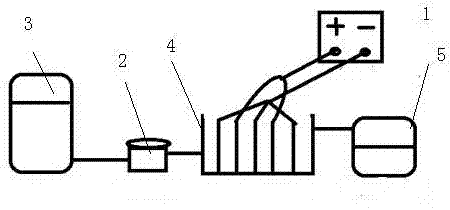

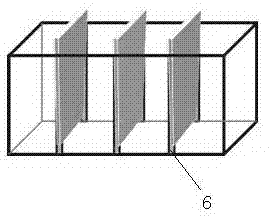

[0032] An electrochemical oxidation device for advanced treatment of amidoximation production wastewater, including a DC stabilized power supply (1), a constant current pump (2), a storage tank (3), an advanced oxidation pool (4), and a drainage storage tank ( 5), the storage tank (3) and the drainage storage tank (5) are respectively connected to the advanced oxidation tank (4), and a constant flow pump (2) is arranged between the storage tank (3) and the advanced oxidation tank (4), so The reaction pool is provided with an electrode array composed of an oxide anode of a titanium sheet substrate and a stainless steel cathode connected to a power supply. The oxide anode of the titanium sheet substrate is based on titanium, and its surface is provided with an intermediate layer and an oxide layer in sequence. The middle layer is SnO 2 and Sb 2 o 5 The mixed layer, the oxide layer is PbO 2 layer;

[0033] The stainless steel cathode is mesh-shaped.

[0034] The inner wall o...

Embodiment 2

[0041] An electrochemical oxidation device for advanced treatment of amidoximation production wastewater, including a DC stabilized power supply (1), a constant current pump (2), a storage tank (3), an advanced oxidation pool (4), and a drainage storage tank ( 5), the storage tank (3) and the drainage storage tank (5) are respectively connected to the advanced oxidation tank (4), and a constant flow pump (2) is arranged between the storage tank (3) and the advanced oxidation tank (4), so The reaction pool is provided with an electrode array composed of an oxide anode of a titanium sheet substrate and a stainless steel cathode connected to a power supply. The oxide anode of the titanium sheet substrate is based on titanium, and its surface is provided with an intermediate layer and an oxide layer in sequence. The middle layer is SnO 2 and Sb 2 o 5 The mixed layer, the oxide layer is PbO 2 layer;

[0042] The stainless steel cathode is mesh-shaped.

[0043] The inner wall of ...

Embodiment example 1

[0057] Implementation Case 1: Using the above-mentioned preparation method, the required anode is used to treat the production wastewater of a caprolactam ammoximation process in Shandong. The quality of the wastewater is: COD about 6400mg·L -1 , about 255mg·L ammonia nitrogen -1 , pH=11-13, through the design of the treatment tank volume 4L; anode area: 30cm 2 (two pieces), cathode area: 30 cm 2 (three pieces);

[0058] The device is first filled with 4L of waste water that has been adjusted to pH=3 (H 2 SO 4 Adjustment), power on under different conditions, first static treatment for 3 hours, to ensure that the 4L wastewater in the treatment pool is qualified, then turn on the constant flow pump, control the inflow and outflow flow and residence time, treat according to the following different conditions, take samples once an hour, and monitor For the COD and ammonia nitrogen of the water samples at the outlet of the pool, each test runs continuously, the COD of the effl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com