Bottom sizing agent for humid environment and preparation method of bottom sizing agent

A wet environment, primer technology, applied in the coating and other directions, can solve the problems of fire, lower than ambient temperature, defective, etc., to avoid the increase of energy consumption and ensure the effect of coating quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The preparation method of the primer used in the humid environment of the present invention includes the following steps:

[0029] Step 1: Add the primer and solvent into a clean container and stir and mix to prepare a primer diluent;

[0030] Step 2: Mix the bridging agent and the solvent to prepare a diluent of the bridging agent;

[0031] Step 3: Mix the catalyst, catalyst promoter and solvent uniformly to prepare a catalyst diluent;

[0032] Step 4: Mix the anchoring agent and the solvent uniformly to prepare an anchoring agent dilution;

[0033] Step 5: Mix the dewatering agent and the solvent to prepare the dewatering agent diluent;

[0034] Step 6. Mix and stir the primer diluent, bridging agent diluent, catalyst diluent, anchor diluent, dewatering agent diluent and solvent in order to prepare a primer that can be used in humid environments ;

[0035] Step 7: Coating a primer that can be used in a humid environment on the surface of the substrate, desolving and curing it in...

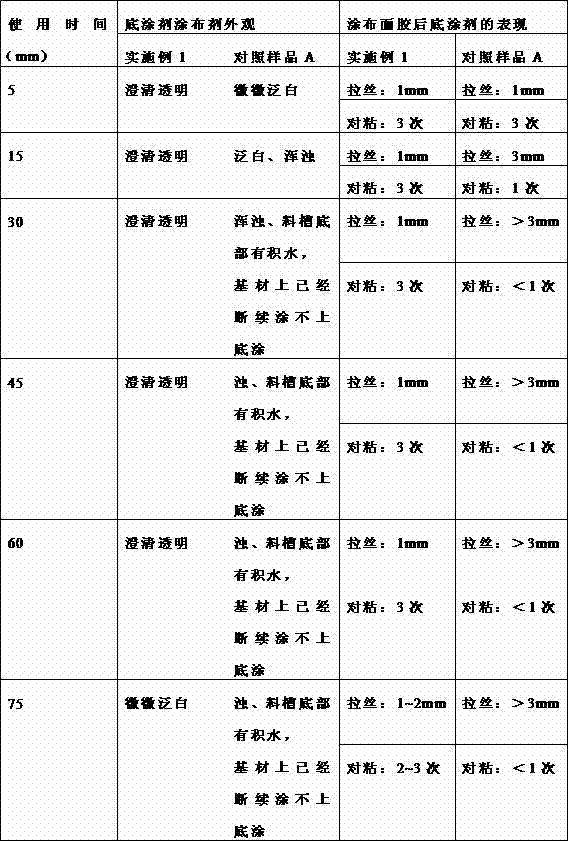

Embodiment 1

[0038] A primer for silicone pressure-sensitive adhesives used in humid environments, including silicone release agent Dow Corning ? 7499, bridging agent Syl-Off ? 7048, organotin catalyst Syl-Off ? 176. Catalytic promoter Syl-Off ? 2-7131 Monooxazolidine water-removing agent ALT-201 with hydroxyl terminal and solvent toluene.

[0039] The preparation method of the primer used in humid environment is:

[0040] First, pour 3000g of toluene into a clean stainless steel container, and then pour 1000g of silicone release agent Dow Corning ? 7499, stir and dissolve for 15 minutes to prepare primer diluent; to 10.0g bridging agent Syl-Off ? Add 100g of solvent toluene to 7048 and stir evenly to prepare a diluent of cross-linking agent; to 30g of organotin catalyst Syl-Off ? Add 400g of toluene solution to 176, stir for 5 minutes and then add 15g of catalytic accelerator Syl-Off ? 2-7131, continue to stir for 5 minutes until uniform, to prepare a catalyst diluent; add 1000g of tolue...

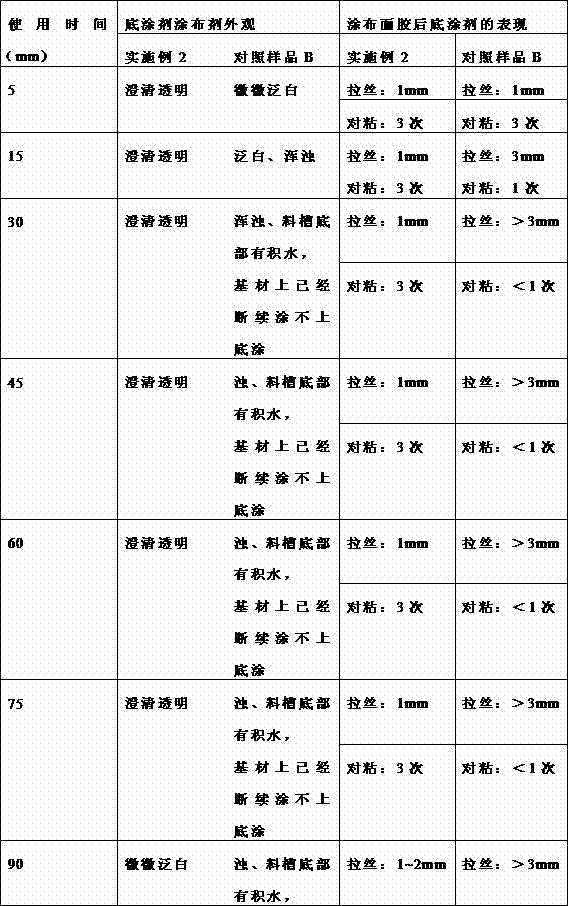

Embodiment 2

[0056] A primer for silicone pressure-sensitive adhesives used in humid environments, including silicone release agent Dow Corning ? 7499, bridging agent Syl-Off ? 7028, organotin catalyst Syl-Off ? 2700, catalytic accelerator Syl-Off ? 2-7131 Anchor agent Syl-Off ? 9176. Monooxazolidine water-removing agent ALT-201 with hydroxyl terminal and solvent toluene.

[0057] The preparation method of the primer for humid environment is:

[0058] First, pour 4000g of toluene into a clean stainless steel container, and then pour 1000g of silicone release agent Dow Corning ? 7499, stir and dissolve for 15 minutes to prepare primer diluent; to 12.0g bridging agent Syl-Off ? Add 100g of solvent toluene into 7028 and stir evenly to prepare a diluent of cross-linking agent; add 30g of organotin catalyst Syl-Off ? Add 400g of toluene solution to 2700, stir for 5 minutes and then add 15g of catalytic accelerator Syl-Off ? 2-7131, continue to stir for 5 minutes until uniform, to prepare the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| cure temperature | aaaaa | aaaaa |

| cure temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com