Liquid filling system for anti-fouling film coating

An antifouling and liquid medicine technology, which is applied in sputtering plating, ion implantation plating, vacuum evaporation plating, etc. It can avoid problems such as unstable temperature, and achieve the effect of eliminating frequent maintenance, improving equipment utilization rate, and eliminating costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

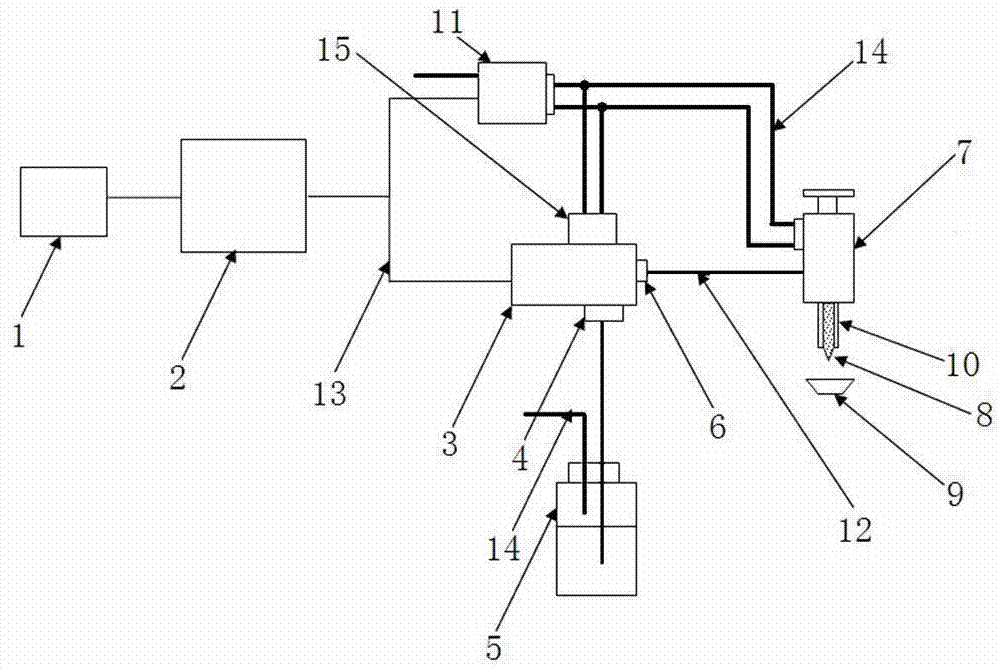

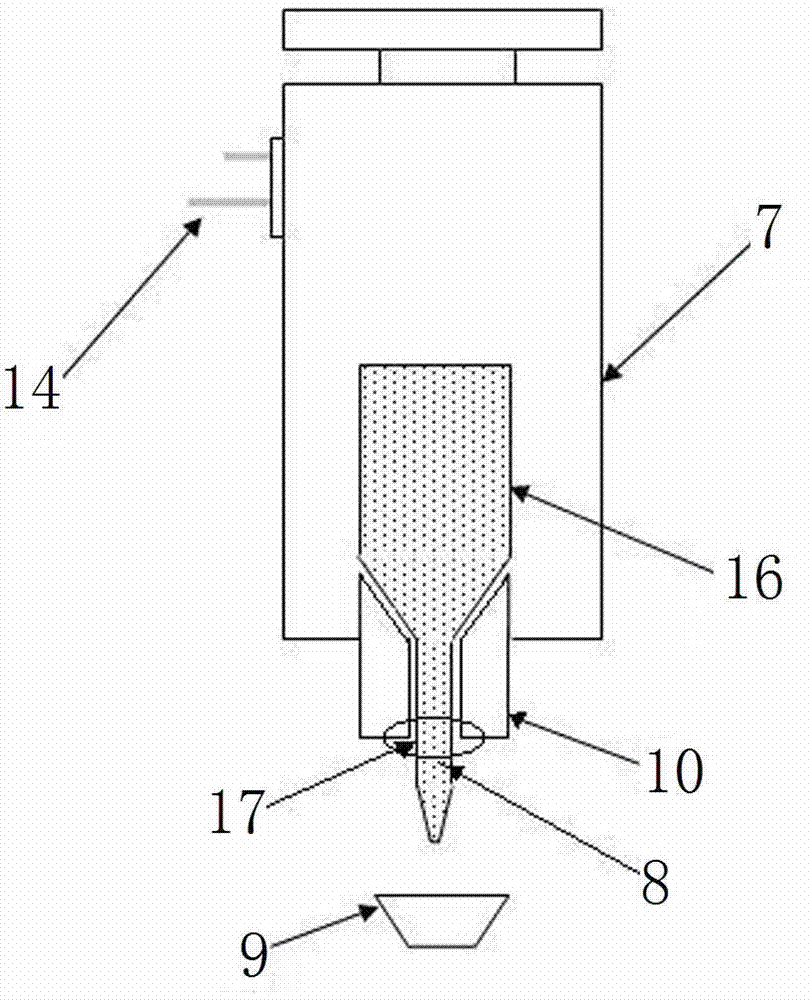

[0017] Embodiment one: if figure 1 As shown, the liquid feeding system for anti-fouling film coating in this embodiment is used to fill the liquid medicine in the liquid medicine bottle 5 of the anti-fouling film material into the crucible 9 for containing the liquid medicine during vacuum coating. The liquid addition system includes a liquid addition controller 2 and a set of liquid addition devices composed of a volumetric metering valve 3 and a medicine drop valve 7 . The liquid adding device has an infusion line, a pneumatic line and a control line, wherein the infusion line refers to the pipeline for transmitting the coating liquid, and the pneumatic line is the gas movement path in the system. These gases are the driving force of the liquid medicine, and the control line is Refers to the circuit that controls the opening and closing of valve components.

[0018] Infusion line: the liquid medicine inlet 4 of the volumetric metering valve 3 and the liquid medicine bottle ...

Embodiment 2

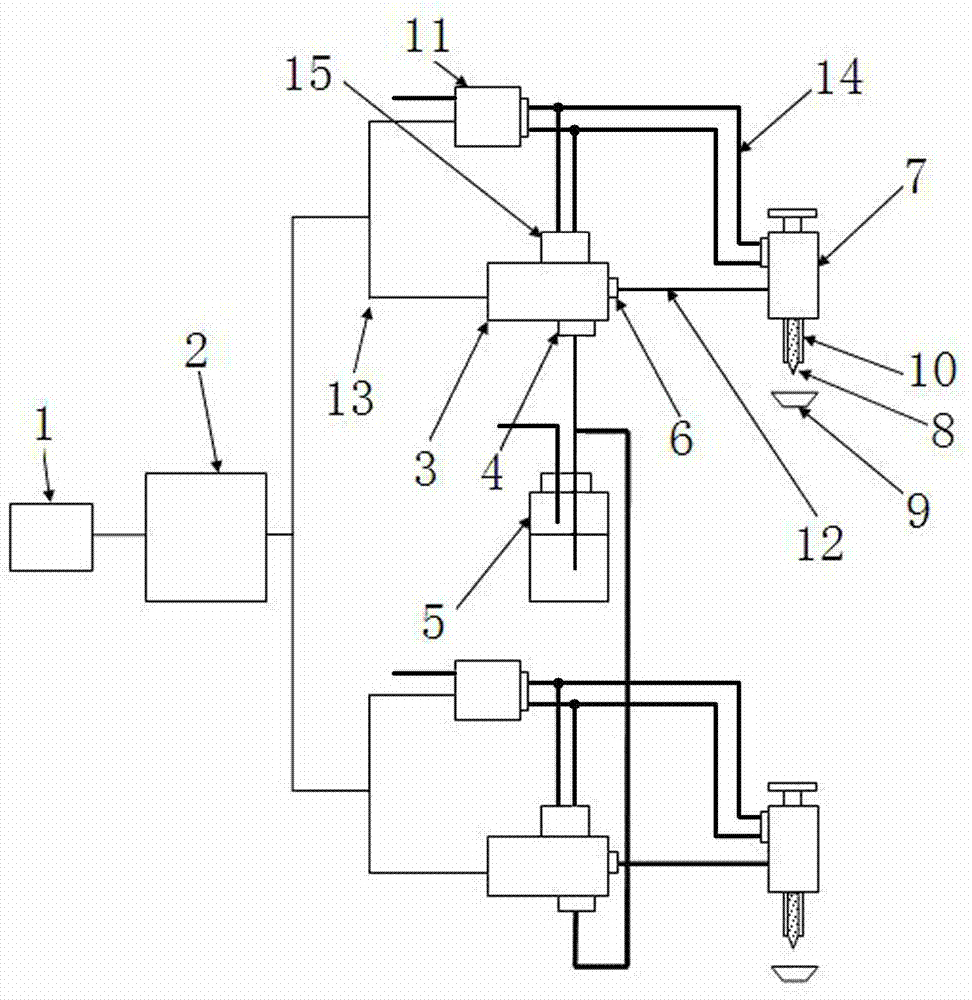

[0029] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the liquid addition system includes a liquid addition controller 2 and two sets of liquid addition devices composed of a volumetric metering valve 3 and a medicine drop valve 7, that is, through a A set of liquid addition controller 2 (may include the host industrial computer 1) controls two sets of liquid addition devices, and the volumetric metering valve 3 in each liquid addition device is connected in parallel with the antifouling membrane material liquid bottle 5, namely The coating liquid can be extracted from the same antifouling film material liquid bottle 5 respectively. The connection mode, control mode and working mode of the remaining components in each liquid adding device are the same as those in Embodiment 1, and will not be repeated one by one.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com