A temperature-adjusting and anti-deformation structure for aluminum electrolytic cell shell

An aluminum electrolytic cell and anti-deformation technology, applied in the field of aluminum electrolytic equipment, can solve problems such as overheating of the side plate steel plate of the tank shell, deformation of the outer arch of the side plate, etc., to prevent overheating of the side plate, avoid local deformation, and strengthen the fastening bearing capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Materials such as flat plates, corrugated plates, cradle frames, hoardings, and ribs used in the embodiments of the present invention are all ordinary steel materials.

[0030] The corrugated plate in the embodiment of the present invention may have a corrugated cross-section that is semicircular, triangular, rectangular, trapezoidal, trapezoidal with rounded corners or a polygonal half-section, and the number of corrugations within the height of the vertical direction is 5-10.

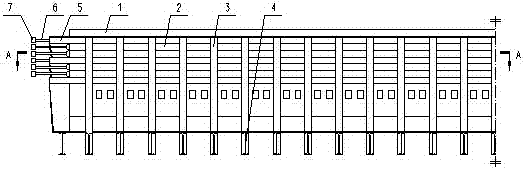

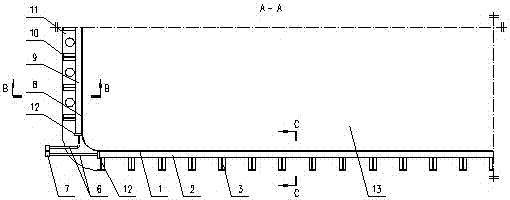

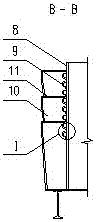

[0031] Embodiment of the present invention: a structure for adjusting the temperature and preventing deformation of the shell of an aluminum electrolytic cell such as figure 1 As shown, the top view structure is as figure 2 As shown, the A-A surface structure is as image 3 As shown, the B-B surface structure is as Figure 4 As shown, the shape of the electrolytic cell shell is an open three-dimensional rectangular structure, including two large side panels (composed of a large inner flat pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com