Method and device for cleaning residual bi-anode electrolyte

A technology of residual double anode and cleaning device, which is applied in the field of electrolytic aluminum anode carbon block production, can solve the problems of excessive equipment occupation and low cleaning efficiency of residual double anode electrolyte, so as to improve production efficiency, shorten cleaning time, and reduce dust pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

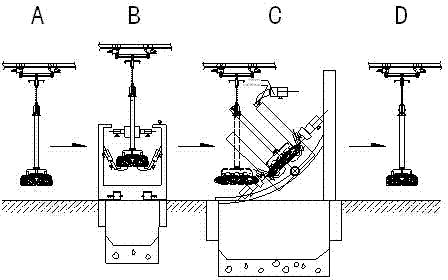

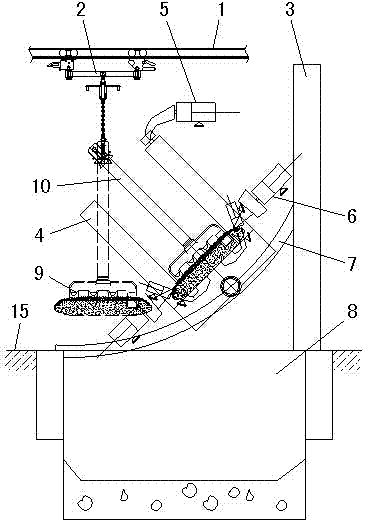

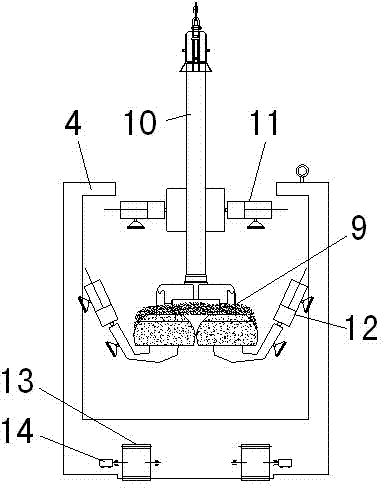

[0032] When the specific implementation is as figure 1 As shown in A, the residual double anode carbon block to be cleaned suspended on the catenary mechanism is sent to the residual double anode carbon block cleaning station through the catenary conveying channel. Such as figure 1 As shown in B, after the residual double anode carbon block to be cleaned enters the tray frame of the cleaning station, the light emitted by the light emitting device on one side of the tray frame is cut off, and the light receiving device on the other side of the tray frame cannot receive light. After the signal, start the clamping device to clamp the aluminum guide rod on the remaining double anode carbon block to be cleaned, and start the jacking mechanism at the same time to tighten the bottom of the remaining double anode carbon block to be cleaned, and tighten the entire remaining double anode carbon block to be cleaned. fixed in the pallet rack. Such as figure 1 As shown in C, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com