Plate type preheater for acid bath, flash evaporation device of plate type preheater for acid bath and alkaline cleaning process

A technology of preheater and acid bath, applied in the field of plate preheater for acid bath and plate preheater flash device for acid bath, can solve the problem of reducing heat transfer coefficient, rapid decay of flash performance, and easy gaps on both sides of the plate. Clogging and other problems, to achieve the effect of smooth flow channel, expansion of heat transfer area, and improvement of plate utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

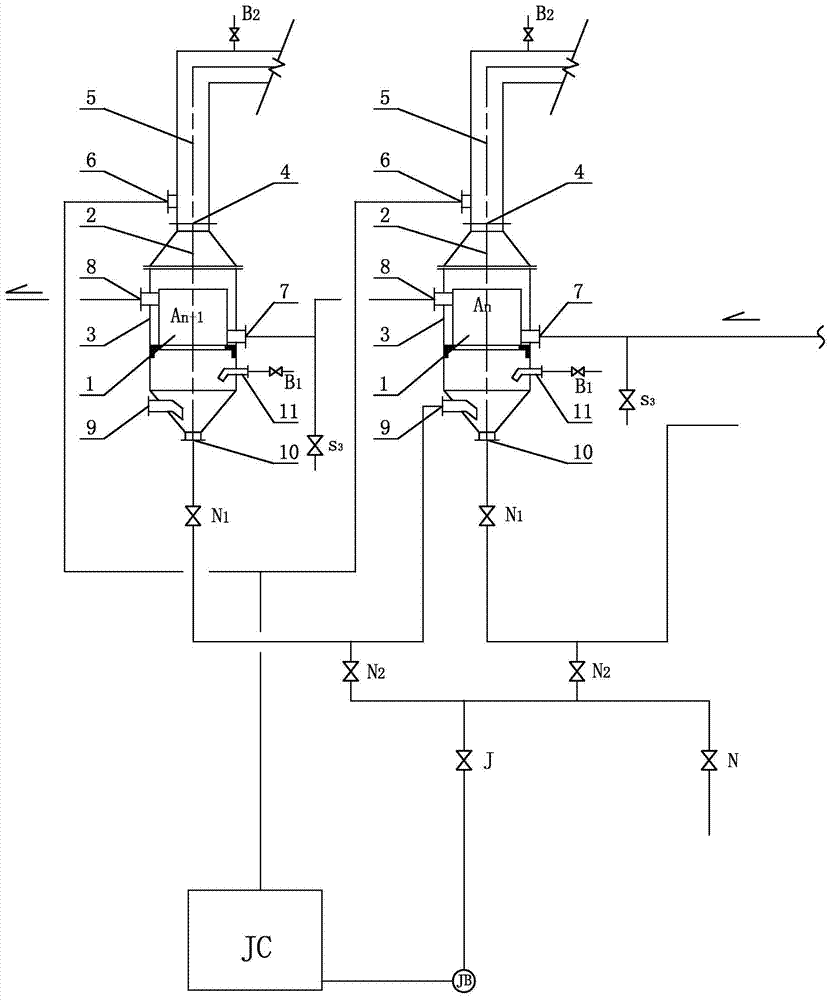

[0073] Such as figure 1 As shown, a plate preheater for an acid bath includes a preheater plate assembly 1, a preheater upper cover 2, and a preheater shell 3; the preheater plate assembly 1 is a plate After being arranged and assembled, the assembly is fixed or welded with screws; the top of the preheater upper cover 2 is provided with a preheater steam inlet 4, and the preheater steam inlet 4 is connected to the preheater steam inlet pipe 5, and the preheater steam The inlet pipe 5 is provided with an alkaline water overflow port 6; the preheater shell 3 is provided with a preheater acid bath inlet 7, a preheater acid bath outlet 8, a flash condensate inlet 9, and a preheater Condensed water outlet 10 and non-condensable gas outlet 11; the steam inlet 4 of the preheater is arranged above the plate gap on the steam side of the plate assembly 1, and the condensed water outlet 10 of the preheater is arranged on the side of the plate assembly 1 Below the gap on the steam side; ...

Embodiment 2

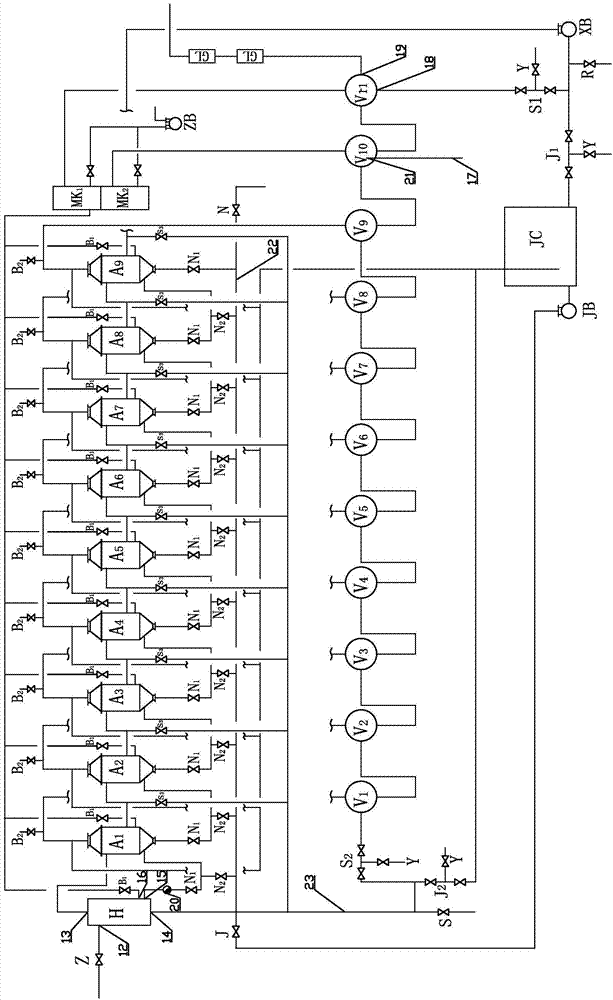

[0075] Such as figure 2 As shown, an acid bath plate preheater flash device, including heater H, preheater A 1 to preheater A 9 and flasher V 1 to flasher V 11 , Condenser MK 1 , Condenser MK 2 , Vacuum pump ZB, circulation pump XB, alkali water tank JC, alkali water pump JB. The preheater A 1 to preheater A 9 Both are equipped with preheater acid bath inlet 7 and preheater acid bath outlet 8, and are connected to corresponding pipe sections; the heater H is provided with H acid bath inlet 13, H acid bath outlet 14 and H condensate outlet 15. The non-condensable gas port 16 of H row, the preheater steam inlet 4 of each stage of preheater are respectively connected with the preheater steam outlet of flash steam of the same level, and the flash evaporator V 10 and flasher V 11 The steam outlets are respectively connected with the condenser MK 2 and condenser MK 1 The steam inlet is connected, the condenser MK 1 and condenser MK 2 They are respectively connected to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com