Mining-method tunnel inner shield receiving construction method

A construction method and mining method technology, applied in tunnels, tunnel linings, mining equipment, etc., can solve the problem of low utilization rate of urban underground space, and achieve the effect of ensuring sustainable development and wide application and solving limitations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] The shield receiving construction method in the built mine method tunnel of the present invention, concrete construction steps are as follows:

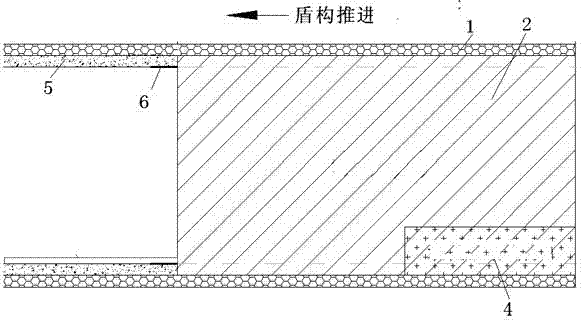

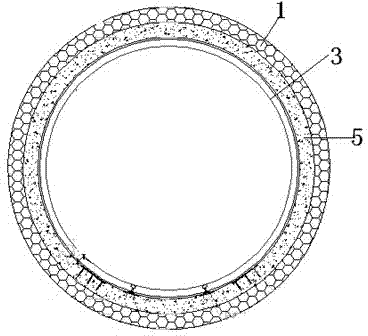

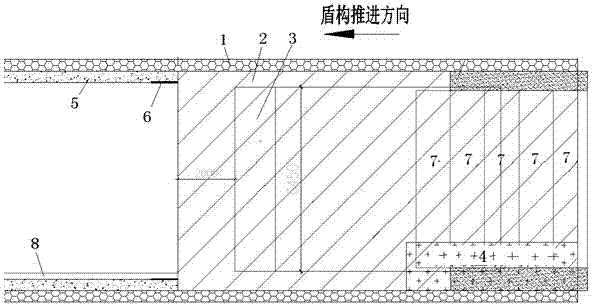

[0061] (1) Determine the reinforcement scope and pouring method ( figure 1 , shown in 2)

[0062]According to the working conditions, it is determined to pour a section of plain concrete reinforcement 2 with a length of about 15m in the clear space of the initial lining 1 in the built mine tunnel. At this time, the remaining 1.7m inverted arch (hard rock 4) has not yet been blasted, so the pouring method is to choose multiple layers of pouring, each layer is 2m thick, and the length is about 4~6m. Remove formwork and supports in time when the reinforcement strength is reached;

[0063] (2) Drainage pipeline made by blasting water seepage on the tunnel surface

[0064] Before the pouring of each layer, bricks should be used to build a drainage ditch on the pouring base surface, and a plastic film should be fixed on the palm ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com