Structure of engine cooling system

A technology of engine cooling and system structure, which is applied in the direction of engine cooling, engine components, machine/engine, etc., can solve the problems of poor comprehensive performance and high thermal load of engine cylinder head, achieve performance improvement, improve stability and reliability, and reduce heat load effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

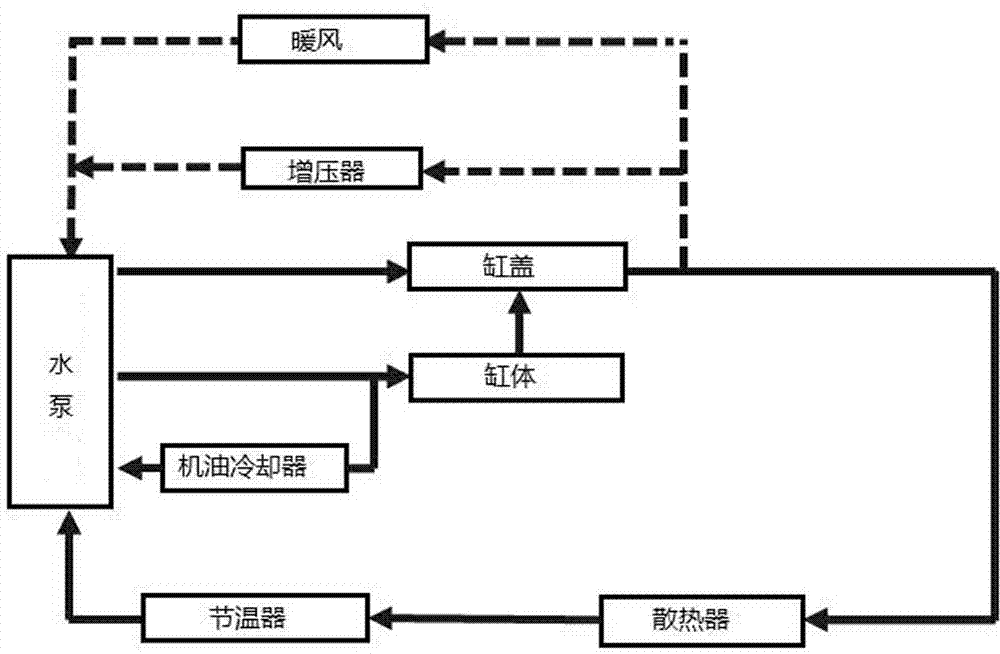

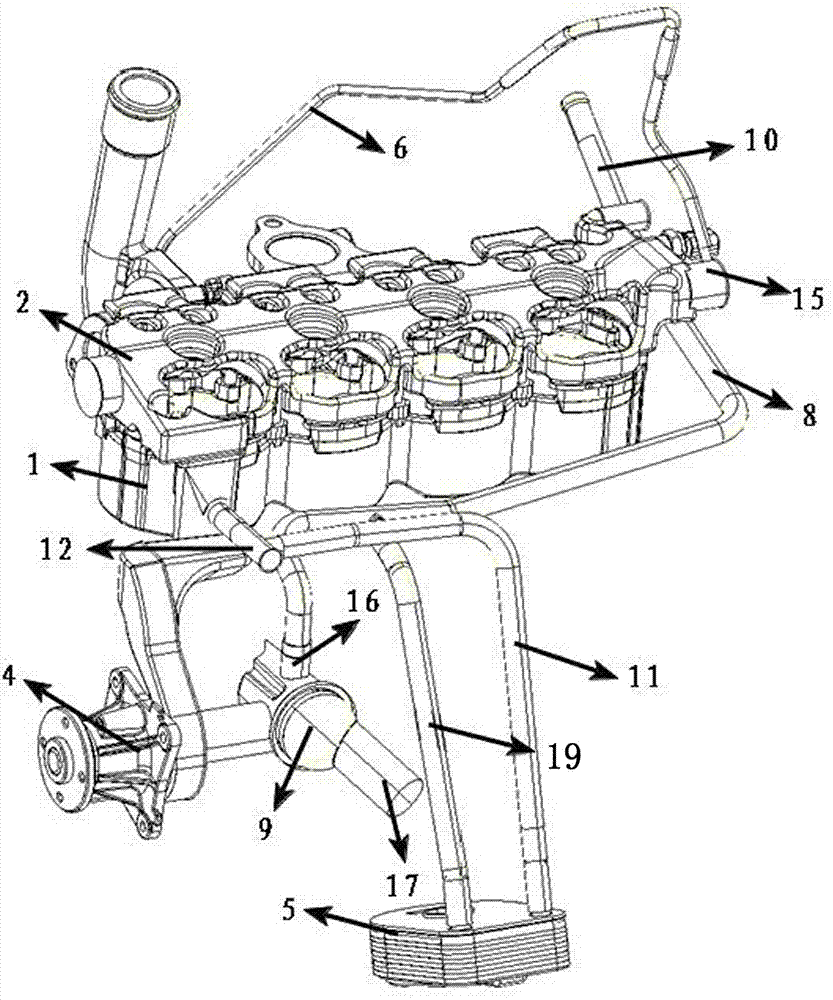

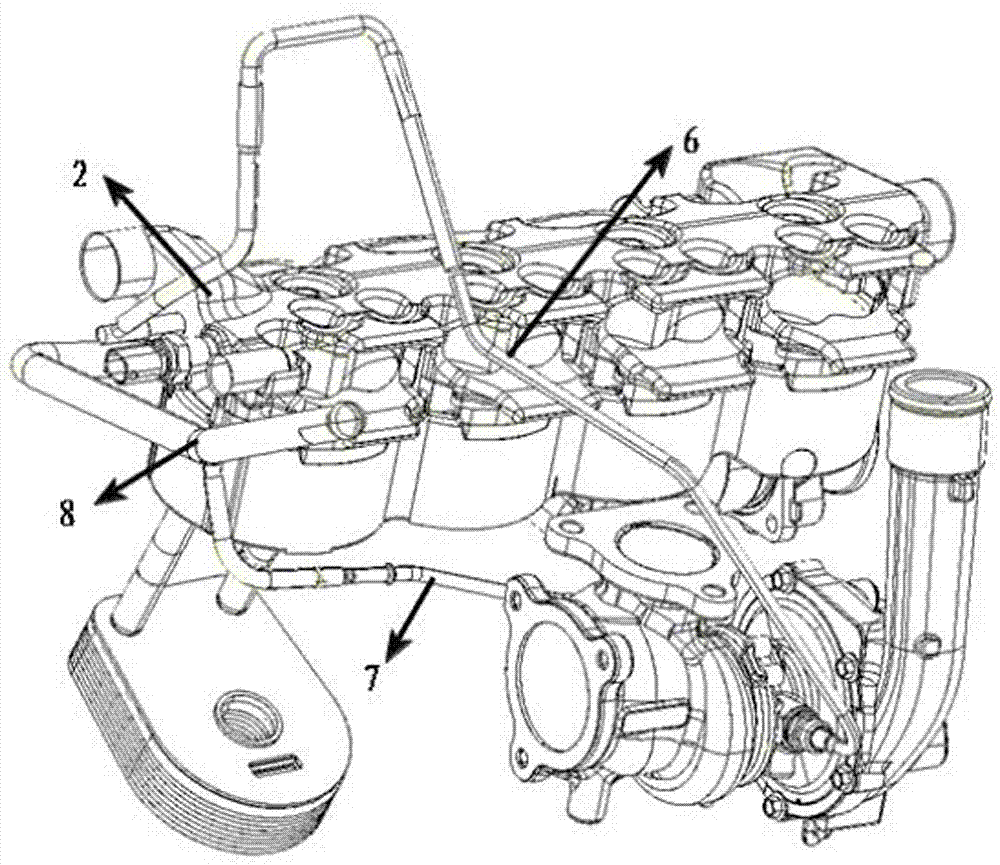

[0015] according to Figure 1~6 The specific structure of the present invention will be described in detail. The engine cooling system structure includes a cylinder water jacket 1, a cylinder head water jacket 2 assembled on the cylinder body water jacket, a cylinder gasket 3 assembled between the cylinder body water jacket and the cylinder head water jacket, and a cylinder head gasket 3 assembled on the front of the cylinder body. The water pump 4, the oil cooler 5 assembled on the air intake end of the cylinder block, the supercharger assembled on the cylinder block and other parts, the cylinder gasket 3 is provided with a number of cylinder gasket water holes 14, and the cooling water of the cylinder head water jacket The cavity communicates with the cooling water cavity of the water jacket of the cylinder body through the water holes of the cylinder pad, and the water pump water inlet is provided with a water pump water inlet water jacket 13 . Among them, the water pump i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com