A balanced solenoid valve with mechanical valve position indicator and manual device

A manual device and indicator technology, applied in the field of solenoid valves, can solve the problems of large volume, large installation space, difficult installation and debugging, etc., and achieve the effect of small volume, small movement friction and smooth movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

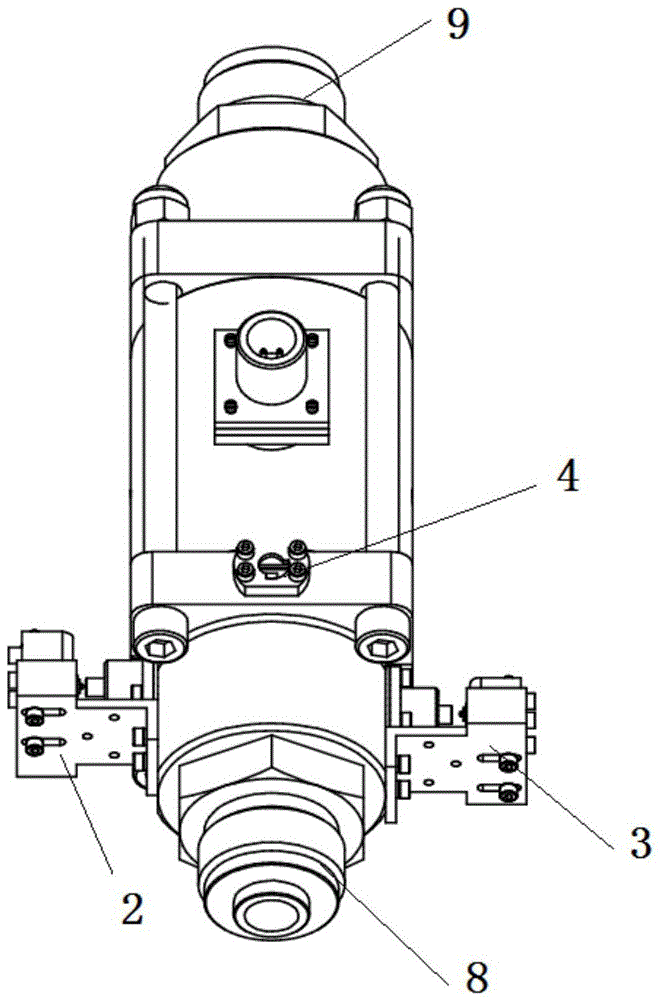

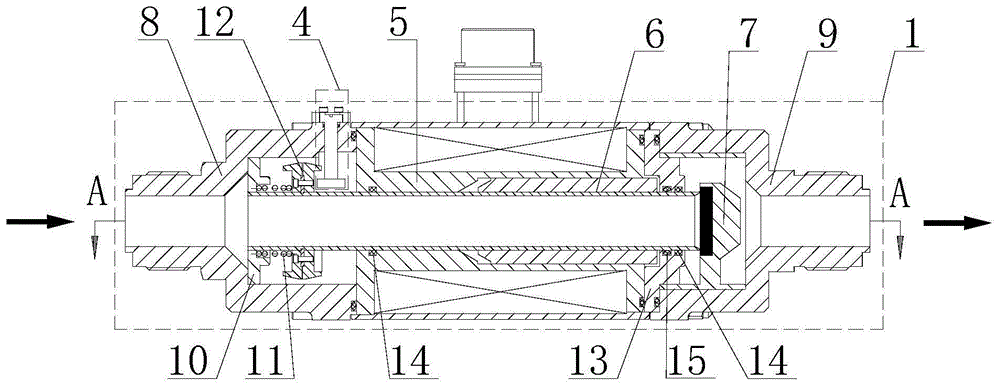

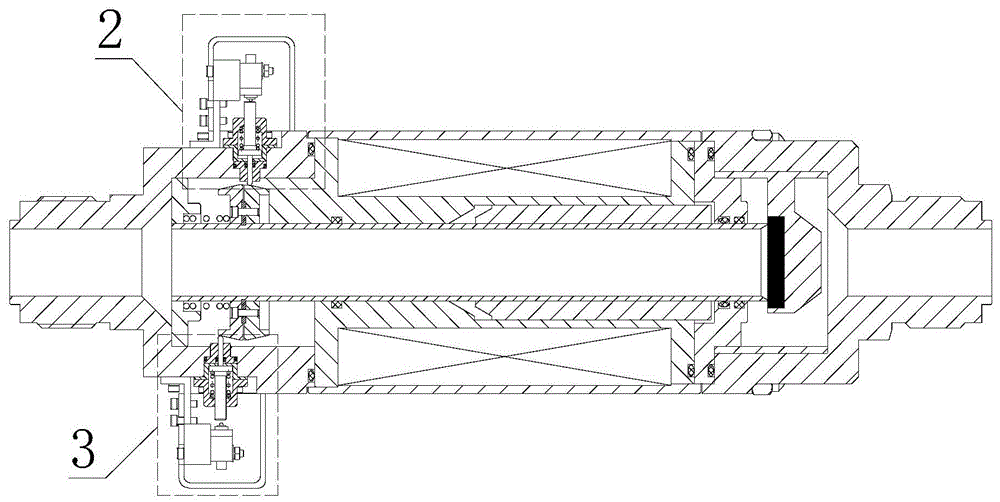

[0024] Such as Figure 1 to Figure 4 As shown, it is a schematic structural diagram of an example of the present invention, which is mainly composed of a main valve 1 , a valve position indicator 2 at a fully closed position, a valve position indicator 3 at a fully open position and a manual device 4 . The main valve 1 includes a coil assembly 5 , a valve core assembly 6 , a valve seat assembly 7 , an inlet flange 8 , an outlet flange 9 , a spring seat 10 , a main spring 11 , a limiting device 12 , and a pressure ring 13 . The system pipeline is respectively connected with the inlet flange 8 and the outlet flange 9; the coil assembly 5 and the valve core assembly 6 form a closed magnetic circuit, and the valve core assembly 6 moves axially guided by the inner hole of the coil assembly 5; the valve core assembly 6 is a split welded structure, which adopts a pressure balance design, and only uses a star-shaped sealing ring 15 to realize dynamic sealing; when the solenoid valve i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com