Steam-utilizing condensate water recycling system for cut tobacco production workshop of cigarette factory

A technology of recycling system and condensate water, applied in the field of cigarette production, can solve the problems of affecting the environment, unable to fully recover condensate water, and high temperature of condensate water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

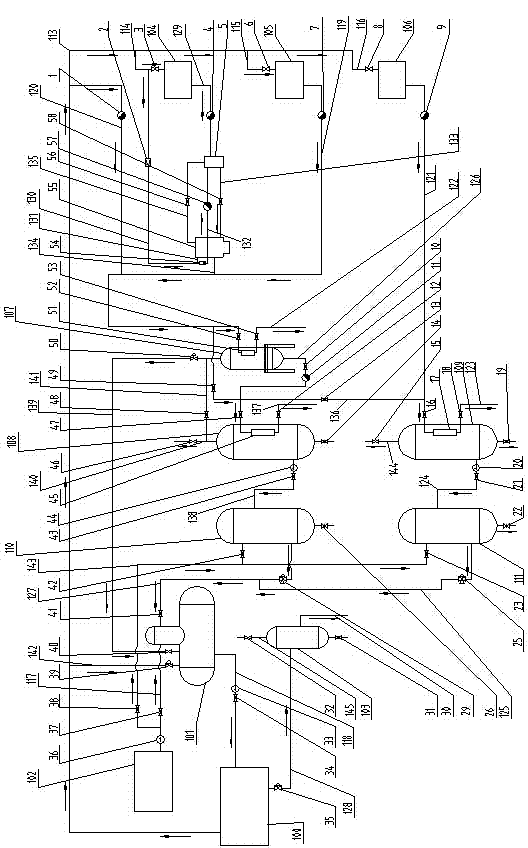

[0033] Such as figure 1 As shown, the steam utilization condensed water recovery system of the cigarette factory silk workshop of the present invention includes a boiler 100, a deaerator 101, a softened water station 102, a regular blowdown expansion tank 103, high-temperature process equipment 104, low-temperature process equipment 105, and a combined air conditioner 106. Flash tank 107, high-pressure condensed water recovery tank 108, low-pressure condensed water recovery tank 109, first iron removal equipment 110 and second iron removal equipment 111;

[0034] The water outlet of the demineralized water station 102 is connected with the water inlet of the deaerator 101 through the first water pipe 117, and the first water pump 36 and the first ball valve 37 are arranged successively along the water flow direction on the first water pipe 117, and the water outlet of the deaerator 101 The second water pipe 118 is connected to the water inlet of the boiler 100, and the second ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com