Header body pressure-bearing type water storage type heat exchanger

A water storage type, heat exchanger technology, applied in the direction of heat exchanger shell, indirect heat exchanger, heat exchanger type, etc., can solve the problems of repeated welding of stainless steel materials, defects in cracking, and high maintenance costs, to reduce After-sales service maintenance cost, resistance to fatigue damage, high product qualification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

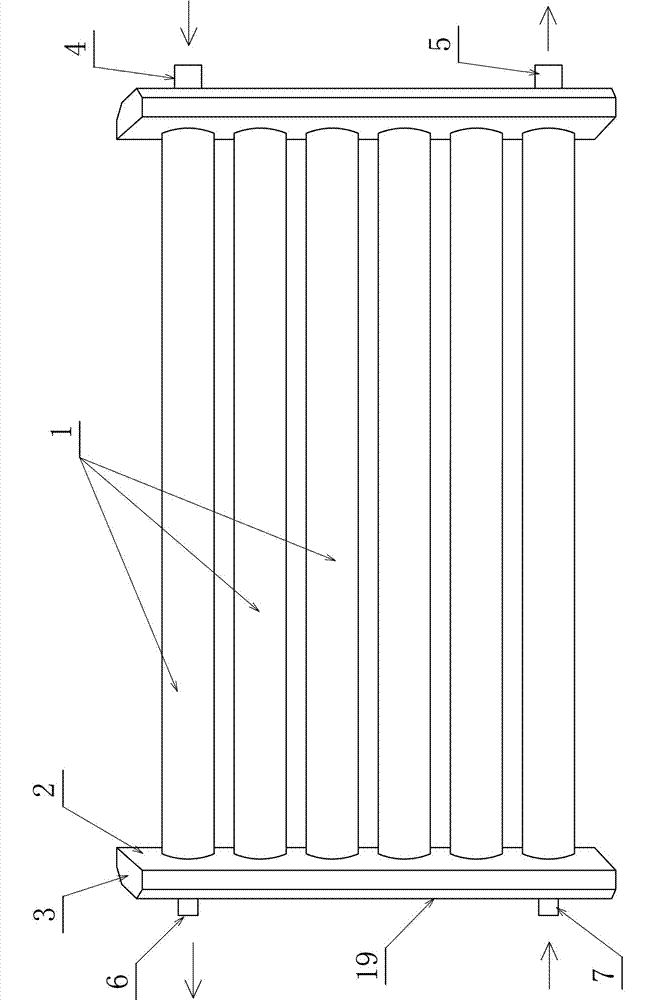

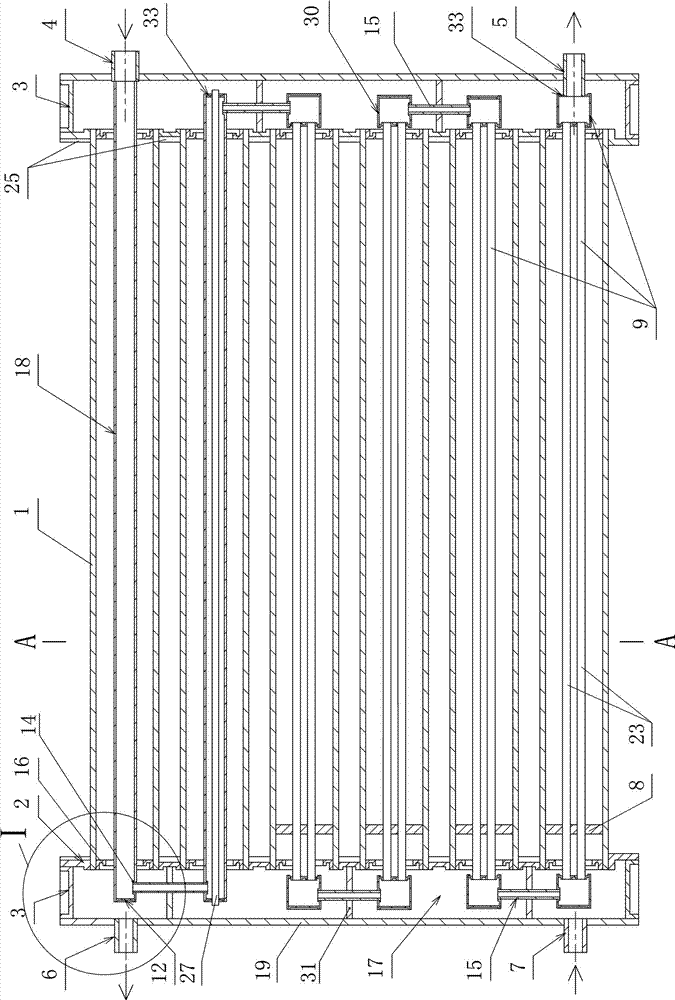

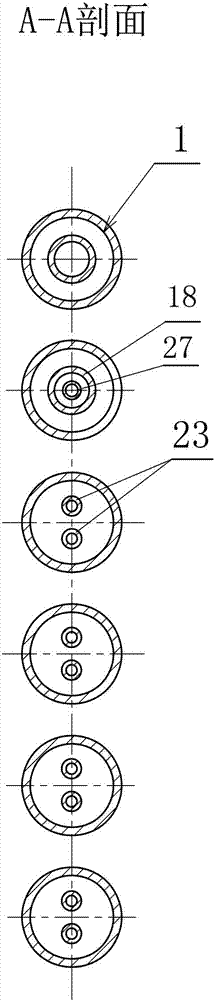

[0045] 1. The pressure-bearing water storage heat exchanger of the header body of the present invention, such as figure 1 , figure 2 , Figure 4 , Figure 5 , Figure 6 , Figure 18 As shown, it includes two header bodies, which are provided with a heating inlet pipe joint 4, a heating outlet pipe joint 5, a cold water inlet pipe joint 7, and a cold water outlet pipe joint 6; the header body includes: the orifice plate inside the header 2. The outer side plate 19 of the header and the end cover plate 3; the space where the orifice plate 2 inside the header and the outer plate 19 of the header are hermetically combined is the inner chamber 17 of the header, and the end cover plate 3 seals off the port of the header; There are a plurality of cold water round pipe installation holes 11 on the orifice plate 2 inside the header; there are mult...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com