Micro device and modeling method for studying gas-solid intrinsic chemical reaction kinetics

A technology of chemical reaction and micro-device, which is applied in the direction of measuring devices, scientific instruments, instruments, etc., can solve the problems of insufficient accuracy, small quality of solid samples, few and difficult gas products, etc., and achieve the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The technical solutions of the present invention will be described in detail below with reference to the accompanying drawings.

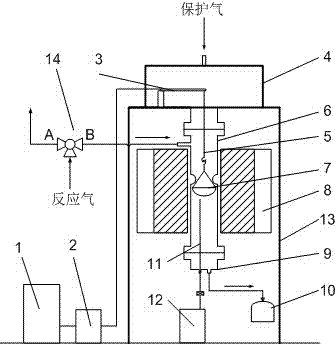

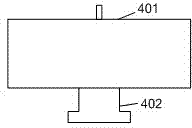

[0032] Such as figure 1 and figure 2 As shown, a micro-device for studying gas-solid intrinsic chemical reaction kinetics of the present invention includes a weighing assembly, a reactor assembly, a bracket 13 and a three-way switching valve 14 . The weighing assembly includes a computer 1 , a data collector 2 , a strain gauge 3 , a glass protective cover 4 and a wire hook 5 . The signal input terminal of the computer 1 is connected with the signal output terminal of the data collector 2, the signal input terminal of the data collector 2 is connected with one end of the strain gauge 3 through a data line, and the other end of the strain gauge 3 is connected with the wire hook 5. The protective glass cover 4 includes a cover body 401 and a hollow boss 402 fixedly connected to the bottom of the cover body 401 . The top of the protective gl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com