Control method used for self-propelled thermal atomizing machine

A control method and self-propelled technology, which is applied in two-dimensional position/channel control and other directions, can solve problems such as manual on-site operation, and achieve the effects of reducing pollution, improving spraying efficiency, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

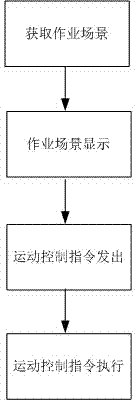

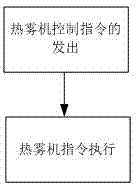

Method used

Image

Examples

Embodiment Construction

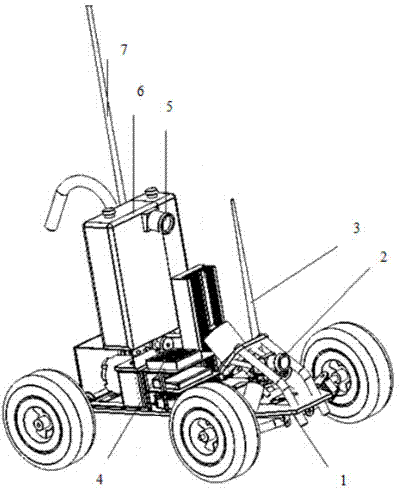

[0037] In order to have a further understanding and understanding of the structural features of the present invention and the achieved effects, the preferred embodiments and accompanying drawings are used for a detailed description, as follows:

[0038] Such as image 3 As shown, a self-propelled heat fog machine based on wireless video transmission control includes a vehicle frame 11 on which a vehicle motion assembly 1 and a heat fog machine body 6 are mounted, and the vehicle motion assembly 1 is mounted on the frame 11 It is used to realize the movement of the vehicle frame 11, and the movement of the hot fog machine body 6 during the spraying operation.

[0039] Such as Figure 4 As shown, the vehicle movement assembly 1 includes a trapezoidal steering mechanism 13 installed on the front portion of the vehicle frame 11. Front wheels 14 are respectively installed at both ends of the front axle of the trapezoidal steering mechanism 13. The trapezoidal steering mechanism 13...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com