A New Type of Laser Amplifier

A technology for laser amplifiers and laser working substances, which is applied to lasers, laser components, phonon exciters, etc., to achieve the effects of improving output power, simple production, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

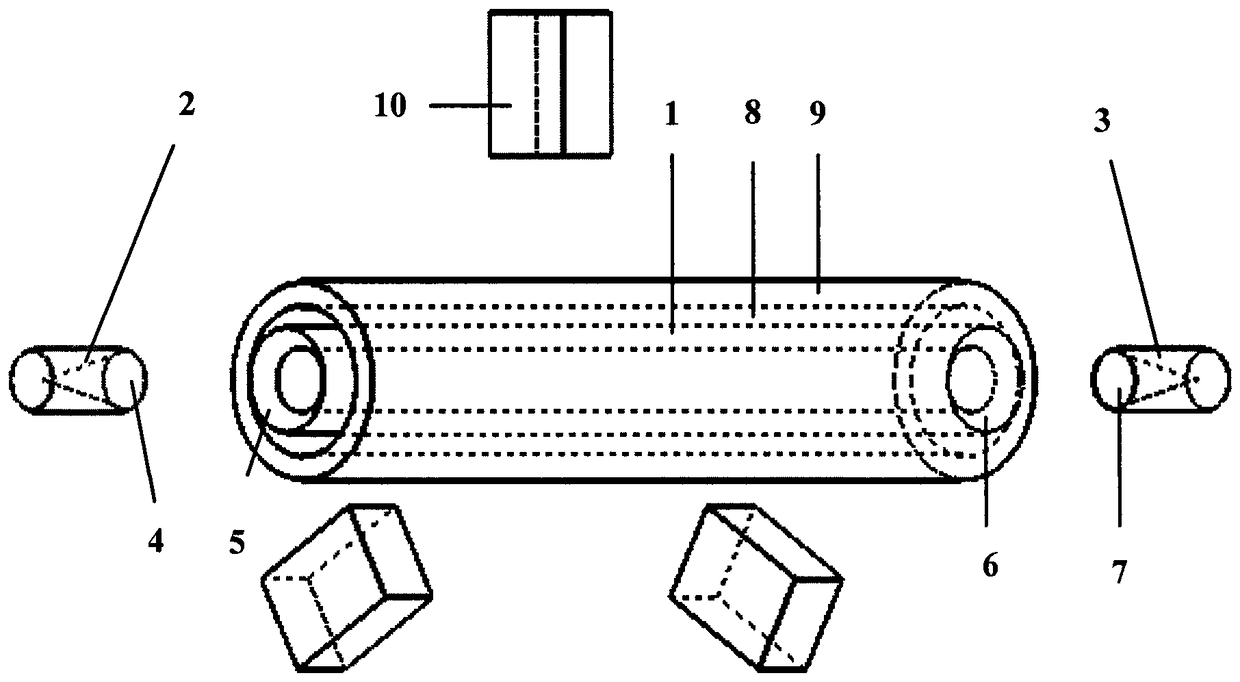

[0027] like figure 1 As shown, the novel laser amplifier of Embodiment 1 of the present invention includes: an optical prism 2, a laser working substance 1 and an optical prism 3 arranged along the optical path.

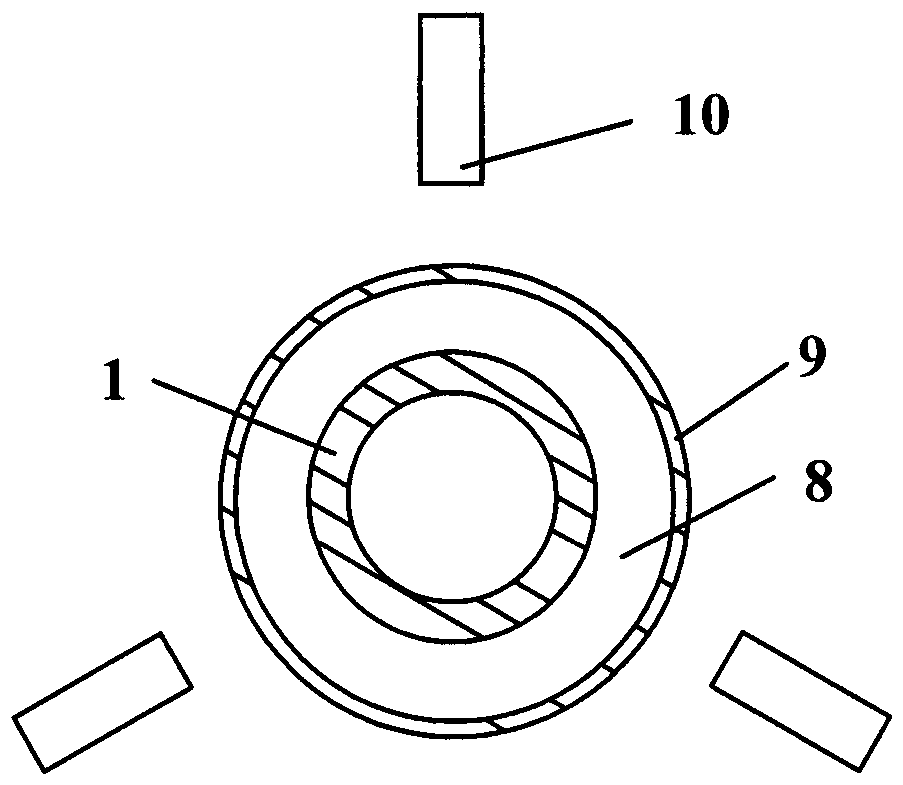

[0028] Wherein, the laser working substance 1 is a tube-shaped rod-shaped crystal, both ends of the tube-shaped rod-shaped crystal are chamfered inwardly, and the cross-section of the tube-shaped rod-shaped crystal is trapezoidal; all surfaces of the laser working substance 1 are precisely polished; The optical prism 2 and the optical prism 3 are the same.

[0029] The optical prism 2 and the optical prism 3 are the same, and the optical prism 2 and the optical prism 3 are in the shape of the cylindrical body after the vertebral body is removed.

[0030] The laser working substance 1, the optical prism 2 and the optical prism 3 have conical surfaces, namely conical surfaces 4, 5, 6, and 7, respectively. The anti-reflection coating layer may not be coated with the c...

Embodiment 2

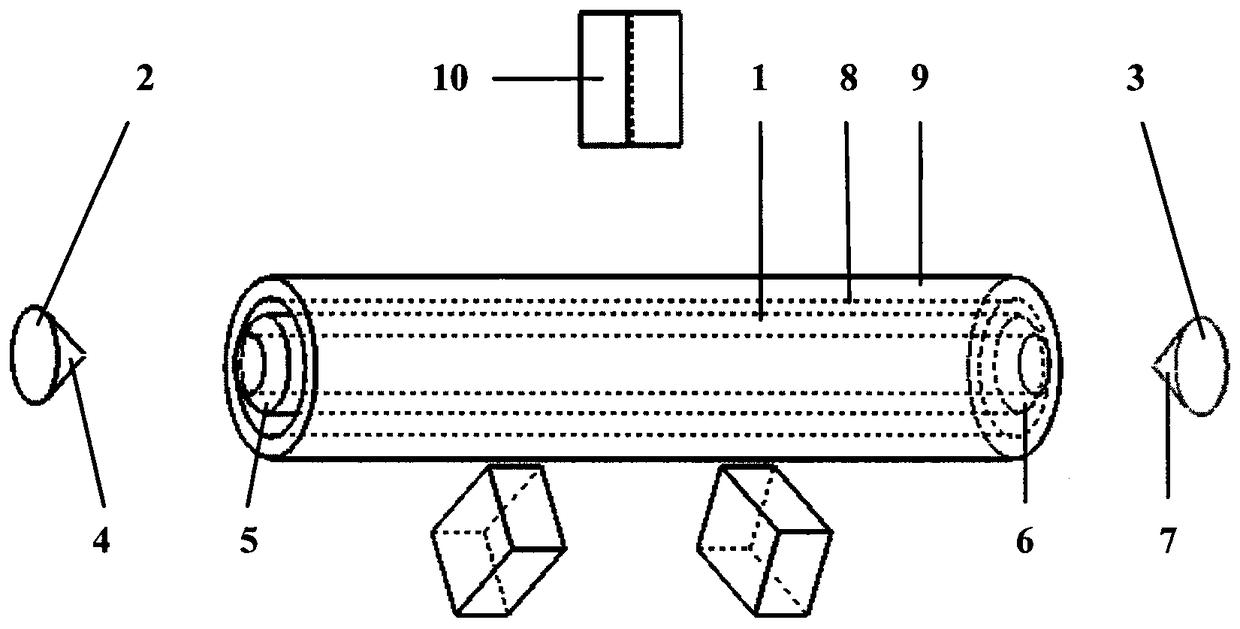

[0036] like figure 2 As shown, the novel laser amplifier of the second embodiment of the present invention includes: an optical prism 2, a laser working substance 1 and an optical prism 3 arranged along the optical path.

[0037] Wherein, the laser working substance 1 is a tube-shaped rod-shaped crystal, both ends of the tube-shaped rod-shaped crystal are chamfered outward, and the cross-section of the tube-shaped rod-shaped crystal is trapezoidal; all surfaces of the laser working substance 1 are precisely polished; The optical prism 2 and the optical prism 3 are the same.

[0038] The optical prism 2 and the optical prism 3 are the same, and the optical prism 2 and the optical prism 3 are cones.

[0039] The laser working substance 1, the optical prism 2 and the optical prism 3 have conical surfaces, namely conical surfaces 4, 5, 6, and 7, respectively. The anti-reflection coating layer may not be coated with the coating layer.

[0040] The inside and / or outside of the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com