Laser amplification system

A laser amplification and laser medium technology, applied in the direction of lasers, laser parts, laser parts, etc., can solve the problems of inability to make large-sized slatted media, limit the size of slatted media, and limit the output laser energy, etc. Improve output beam quality, small thickness and low thermal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

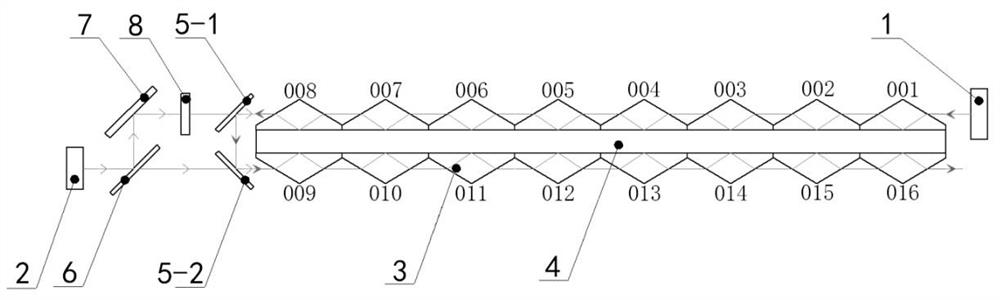

[0027] This embodiment proposes a laser amplification system with a structure such as figure 1 As shown, it includes: seed source 1, pump source 2, gain medium group 3 composed of 16 gain medium units, heat sink 4, first dichroic mirror 5-1, second dichroic mirror 5-2, polarizer 6 , total reflection mirror 7 and 1 / 2 wave plate 8.

[0028] The 16 gain medium units are symmetrically arranged on both sides of the heat sink 4 in turn, the 8 gain medium units on the upper side of the heat sink 4 are numbered from 001 to 008, and the 8 gain medium units on the lower side are the same as the 001 on the upper side There is a one-to-one correspondence between No. 008 and No. 008 gain medium units, and they are numbered sequentially from No. 016 to No. 009;

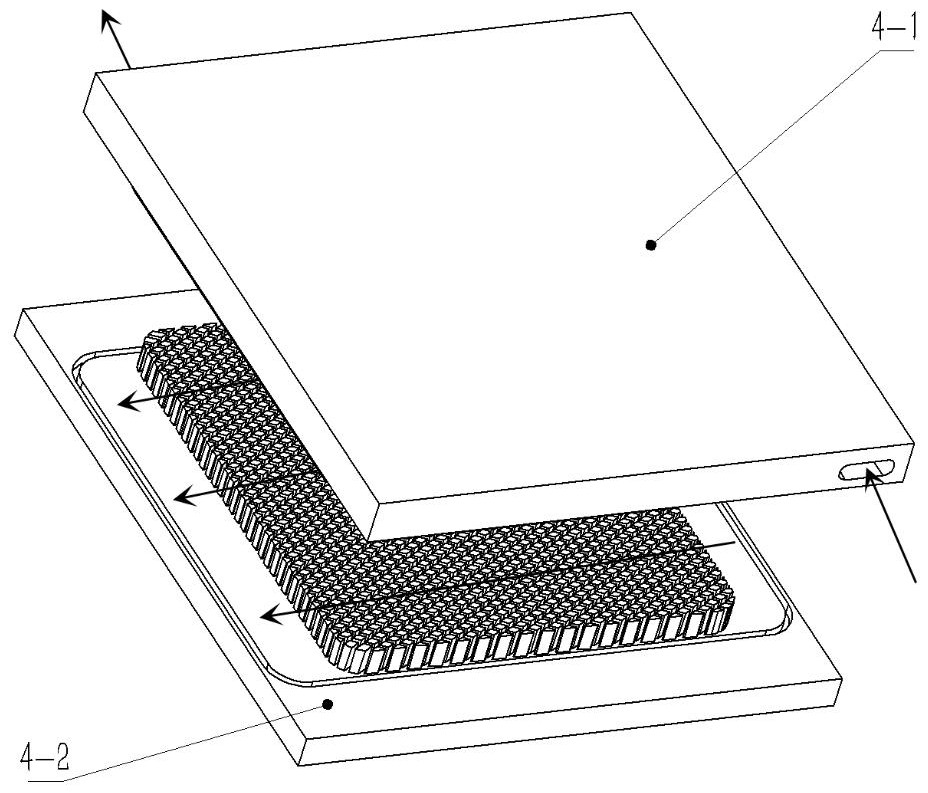

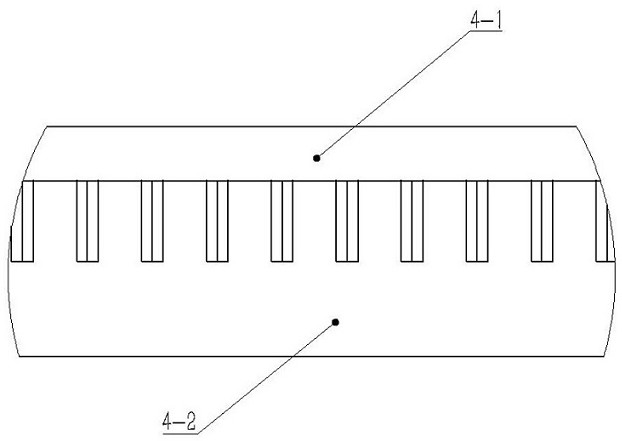

[0029] The gain medium unit is composed of a thin sheet gain medium bottom doped with active ions and a pure matrix laser medium top undoped with active ions, and the bottom of the thin sheet gain medium connects with the heat sin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com