Liquid/air cooling sheet laser, gain module and wavefront distortion self-compensation method

A thin-film laser, gain module technology, applied in the field of lasers, can solve the problems of poor laser output beam quality, large wavefront distortion value, difficult application, etc., to improve beam quality, reduce wavefront distortion, and implement reliable effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] This embodiment discloses a self-compensation method for wavefront distortion of a gain module of a liquid / air-cooled sheet laser.

[0033] Direct liquid / air-cooled thin-film lasers usually immerse the thin solid gain medium directly in the cooling medium. The matrix materials of commonly used sheet solid gain media mainly include the following categories: 1. Glass; 2. Oxide, such as sapphire, garnet, alumina and sulfur oxide; 3. Phosphate and silicate; 4. Tungstic acid Salt, molybdate, vanadate and beryllium; 5. Fluoride; 6. Ceramic materials. Among these materials, some materials have a positive thermo-optic coefficient, such as yttrium aluminum garnet (YAG); some materials have a negative thermo-optic coefficient, such as yttrium lithium fluoride (YLF). The cooling media commonly used in direct liquid-cooled thin-film lasers mainly include deionized water, heavy water, carbon tetrachloride, tetrachloroethylene, siloxane, aromatic compounds, halogenated hydrocarbons,...

Embodiment 2

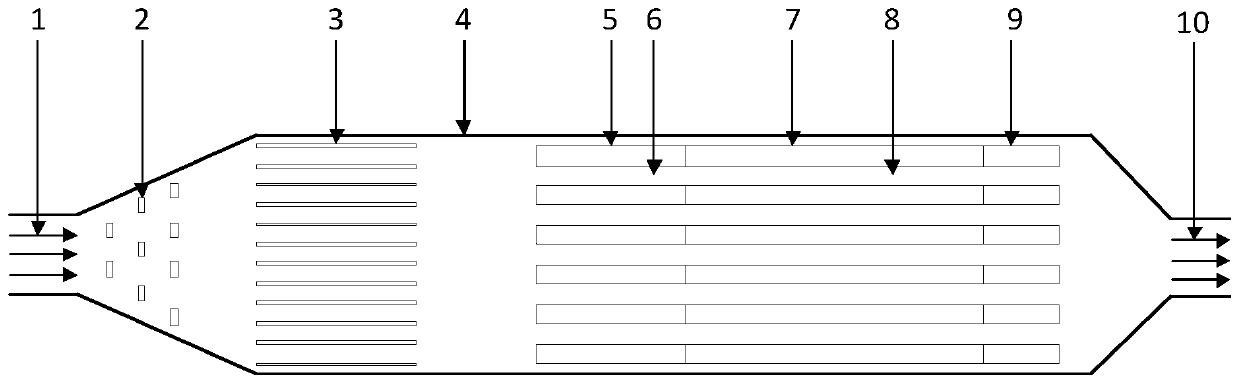

[0039] See attached figure 1 , this embodiment discloses a gain module of a liquid / air-cooled sheet laser, which includes a cooling medium 8 and a gain medium 7, the gain medium is formed with a flow channel 6, the cooling medium 8 directly flows into the flow channel 6, and after flowing through the flow channel 6, the gain medium 7 is cooled, and the cooling medium 8 is a liquid cooling medium and / or a gas cooling medium; the thermo-optic coefficient of the cooling medium 8 is opposite in polarity to that of the gain medium 7.

[0040] In front and / or behind the gain medium 7, a flow field homogenization device 3 is arranged to homogenize the cooling flow field entering the gain module. Further, at the inlet of the cooling medium, a cooling flow field rectification device 2 is also provided to rectify the cooling flow field and improve the uniformity of the flow field.

Embodiment 3

[0042] Such as figure 1 As shown, this embodiment discloses a gain module of a liquid / air-cooled sheet laser, which includes a cooling flow field rectification device 2, a flow field homogenization device 3, a gain module outer frame 4, and a gain medium pre-extension section 5, The laser gain medium 7, and the gain medium is equipped with an extension section 9. The gain medium is formed with flow channels 6 . The cooling medium 8 directly enters the gain module through the inlet 1 of the gain module outer frame 4, passes through the flow field rectifying device 2 and the flow field homogenizing device 3 for homogenization, flows into the flow channel 6, flows out from the cooling medium outlet 10, and flows through the flow In the process of track 6, the gain medium 7 is cooled, and the cooling medium 8 is a liquid cooling medium and / or a gas cooling medium; the thermo-optic coefficients of the gain medium 7 and the cooling medium 8 are opposite in polarity. The flow field...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com