Composite pane with electrical contact-making means

A composite sheet, electrical contact technology, applied in the direction of connecting contact material, conductive connection, ohmic resistance heating parts, etc., can solve the problems of difficult composite sheet manufacturing, reduce thermal load, reduce current flow , to create a simplified effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

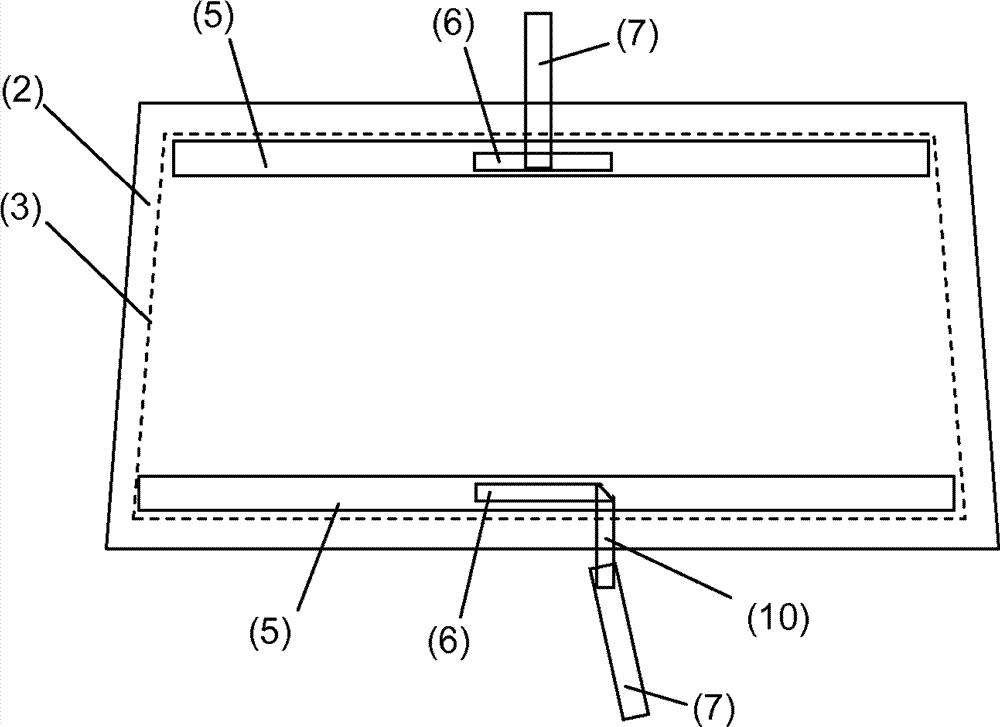

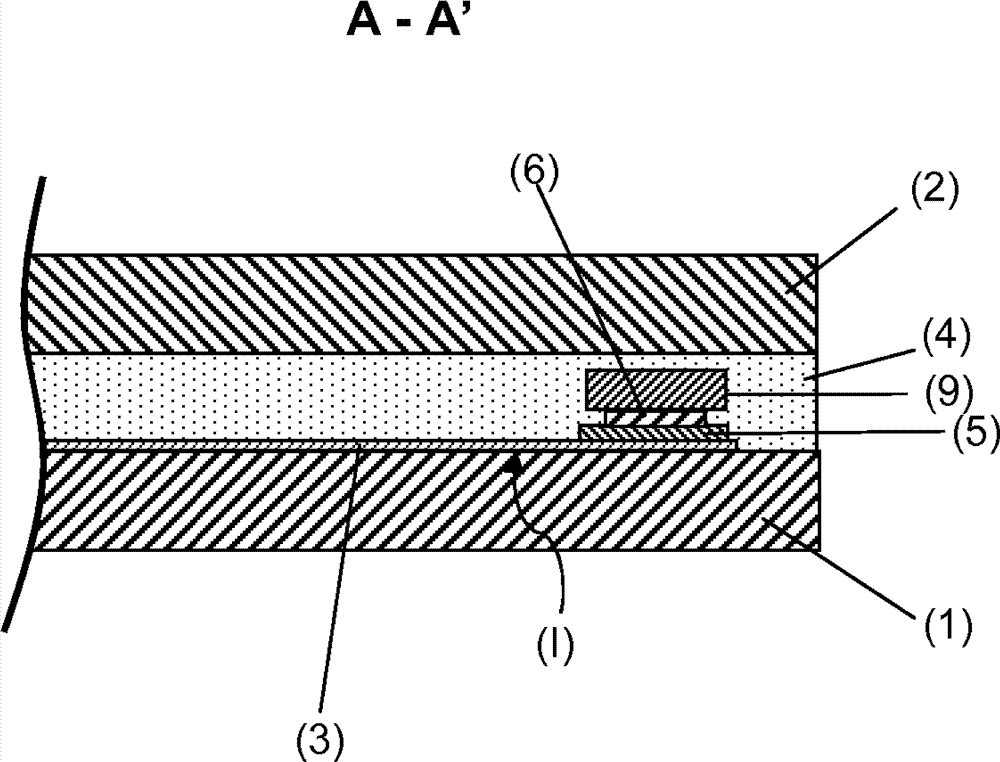

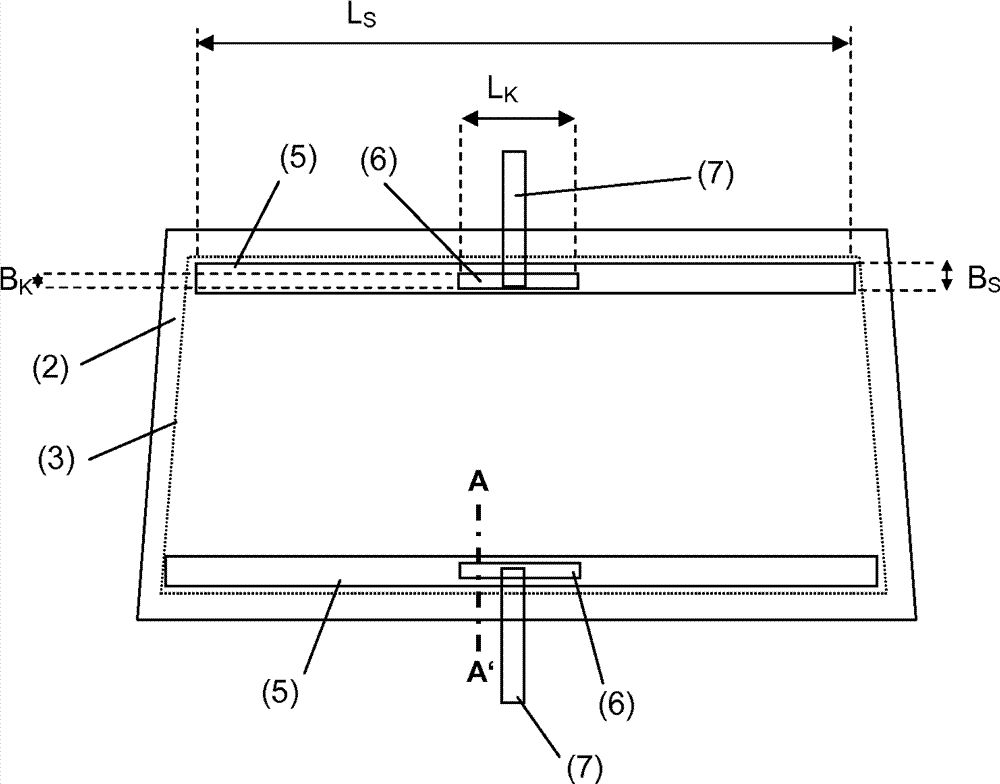

[0103] figure 1 with figure 2 The details of one configuration of the composite sheet according to the invention with electrical contacts are shown in each case. The transparent composite sheet comprises a first sheet 1 and a second sheet 2 which are connected to each other via a thermoplastic interlayer 4 . The composite sheet is a windshield of a passenger car, wherein the first sheet is arranged to face the interior in the installed position. The first sheet 1 and the second sheet 2 consist of soda lime glass. The thickness of the first sheet 1 is 1.6 mm, and the thickness of the second sheet 2 is 2.1 mm. The thermoplastic intermediate layer 4 consists of polyvinyl butyral (PVB) and has a thickness of 0.76 mm. On the inner side surface (I) of the first sheet 1 is applied a conductive coating 3 . The electrically conductive coating 3 is a layer system comprising, for example, three electrically conductive silver layers which are separated from one another by a dielectr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com