Fish roasting stove

A fish grill and casing technology, applied in the field of fish grills, can solve the problems of increased charcoal usage, slag falling and fragmentation, and potential safety hazards, so as to reduce the loss of heat, reduce energy waste, and be safe and reliable sex high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with accompanying drawing with specific embodiment:

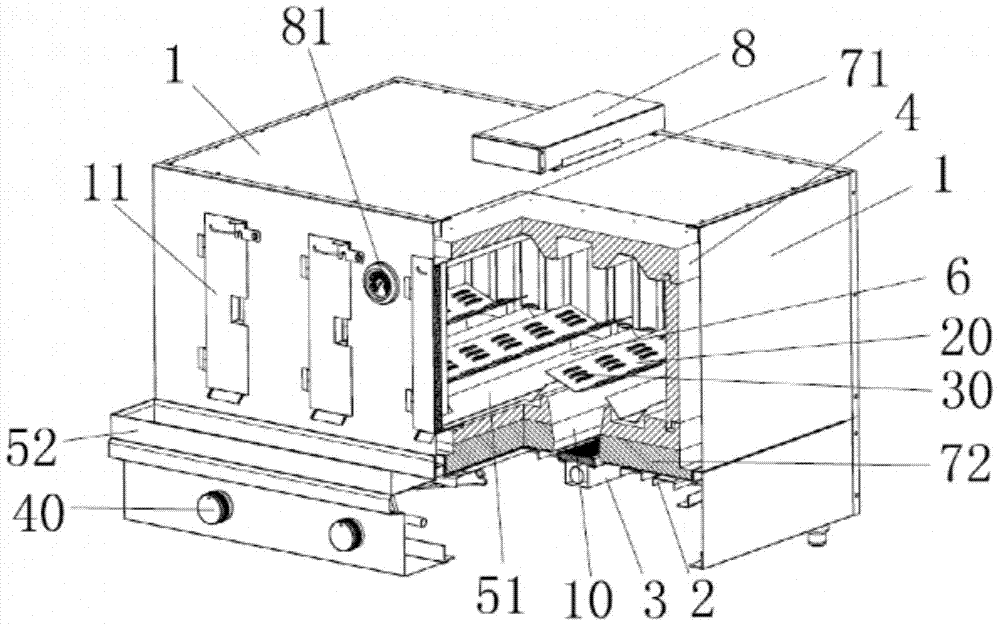

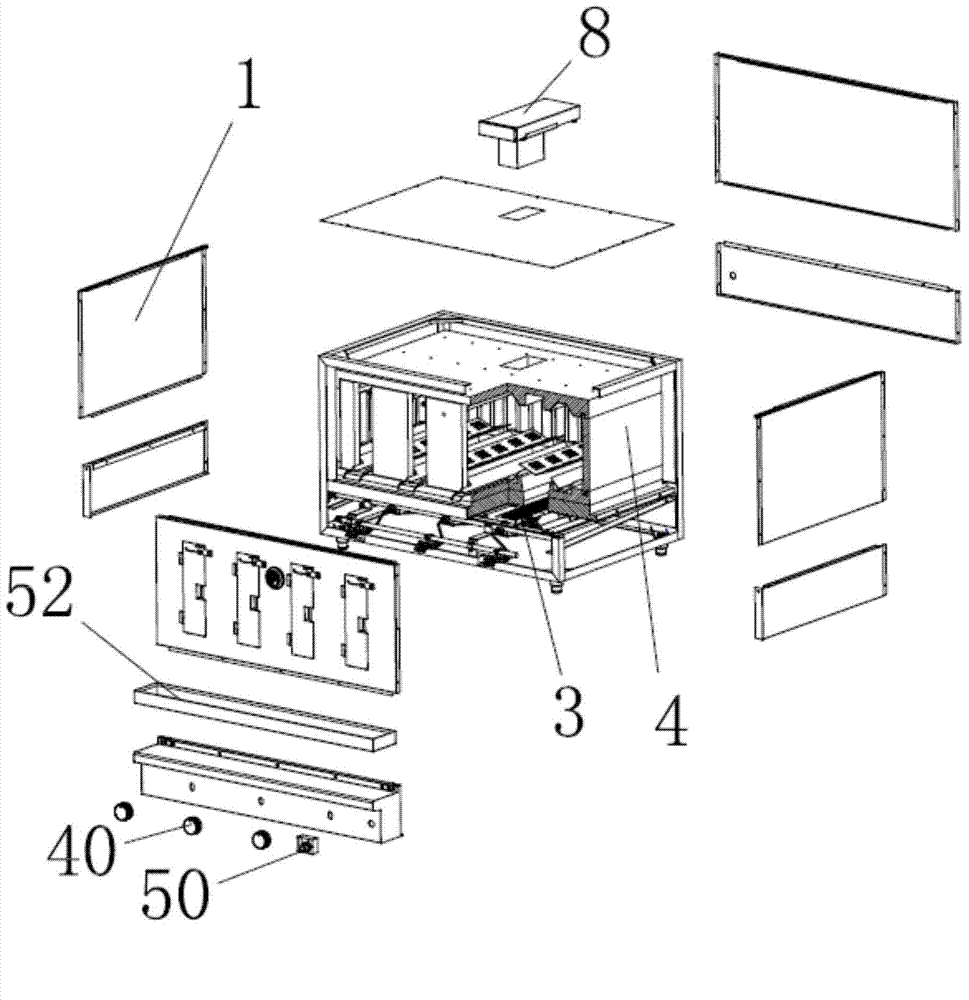

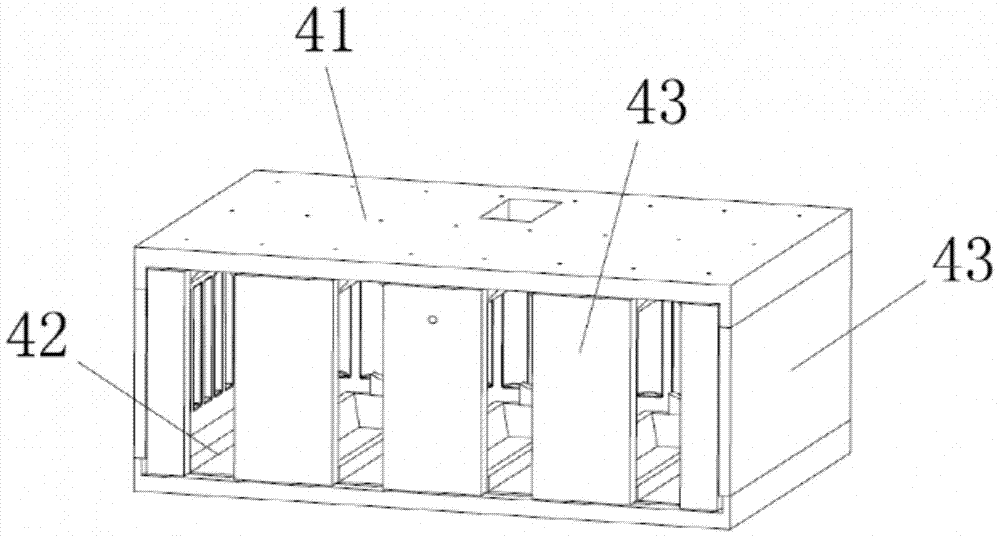

[0038] Reference attached figure 1 - attached Figure 8As shown, a fish grill includes a shell 1 with a door 11, a bracket 2 is arranged inside the shell 1, a burner group 3 is arranged on the bracket 2, and a refractory brick liner 4 is arranged above the burner group 3 , the refractory brick liner 4 includes a top plate 41, an oil guide groove 51 is arranged above the burner group 3, and a circulating heating space 6 is formed by the top plate 41 and the oil guide groove 51; There are glass fibers and a first ceramic fiber board 71 (not shown in the figure), and a second ceramic fiber board 72 is arranged below the refractory brick liner 4; a smoke exhaust port 8 is arranged on the top plate 41; such a structural design is reasonable and environmentally friendly , safe, the grilled fish tastes delicious and has a good taste; in addition, the des...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com