Ultrasonic cleaning machine for decreasing vibration and reducing noise

A technology of ultrasonic wave and washing machine, which is applied in the direction of liquid cleaning methods, cleaning methods and utensils, chemical instruments and methods, etc., which can solve the problems of vibration noise and pollution, and achieve the effect of reducing vibration and noise pollution and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

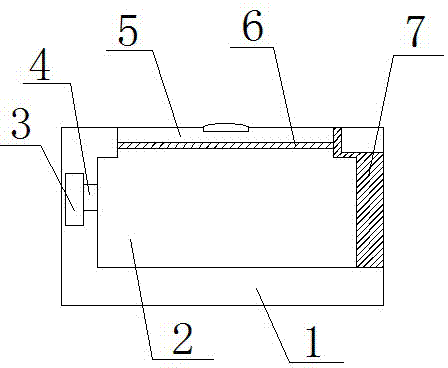

[0014] For the defects of vibration and noise pollution when the ultrasonic cleaning machine works, the present invention provides a method such as figure 1 The shown shock-absorbing and noise-reducing ultrasonic cleaning machine includes a box body 1, a cleaning container 2 in the box body 1, an ultrasonic oscillation device 3, an ultrasonic transducer 4 and a sealing cover 5, and the inner surface layer of the sealing cover 5 is A sound-absorbing layer 6 is provided, and a shock-absorbing interlayer 7 is provided between the box body 1 and the cleaning container 2 . The ultrasonic cleaning machine is provided with a sound-absorbing layer and a shock-absorbing layer, which can effectively reduce vibration and noise pollution.

Embodiment 2

[0016] On the basis of Embodiment 1, the sound-absorbing layer 6 and the sealing cover 5 are bonded by Velcro. The sound-absorbing layer 6 is an environmentally friendly sound-absorbing cotton, and the sound-absorbing layer 6 can be disassembled and bonded freely. After too much water and dust, it can be easily removed for cleaning or replacement; the shock-absorbing interlayer 7 is on the opposite side of the ultrasonic oscillation device 3, and the shock-absorbing interlayer 7 is made of rubber material. This structure is effective Aiming at the vibration generated by the ultrasonic oscillation device 3, the vibration is reduced, thereby reducing noise pollution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com