Corrosion-resistant and penetration-resistant material and production method thereof

A production method and penetration-resistant technology are applied in the field of new materials with strong corrosion resistance and penetration resistance, which can solve the problems of difficulty in compounding graphite-resin composite materials, and achieve the effects of excellent thermal conductivity and excellent corrosion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Preparation of graphite material modifier:

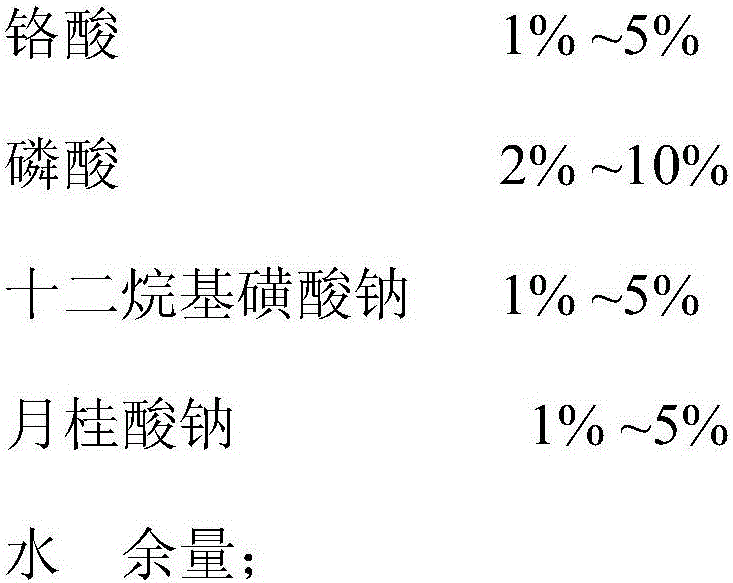

[0028] The graphite material modifier is an aqueous solution, including 3% of chromic acid, 2% of phosphoric acid, 5% of sodium dodecylsulfonate, 2% of sodium laurate and the rest of water, and the above amounts are percentages by mass.

[0029] As a graphite material modifier, it has the following characteristics, which can effectively improve the composite degree between PTFE resin and graphite: chromic acid and phosphoric acid react with the graphite surface to enhance the hydrophilicity of the graphite surface. However, sodium dodecylsulfonate and sodium laurate are used as surfactants, and their hydrophilic ends are more likely to combine with the hydrophilic graphite surface. After the combination, the affinity between the graphite surface and the polytetrafluoroethylene resin is significantly improved. strengthen.

[0030] (2) Modification of graphite substrate:

[0031] Heat the graphite substrate to more than 2...

Embodiment 2

[0037] (1) Preparation of graphite material modifier:

[0038] The graphite material modifier is an aqueous solution containing 5% of chromic acid, 10% of phosphoric acid, 3% of sodium dodecylsulfonate, 5% of sodium laurate and the rest of water.

[0039] As a graphite material modifier, it has the following characteristics, which can effectively improve the composite degree between PTFE resin and graphite: chromic acid and phosphoric acid react with the graphite surface to enhance the hydrophilicity of the graphite surface. However, sodium dodecylsulfonate and sodium laurate are used as surfactants, and their hydrophilic ends are more likely to combine with the hydrophilic graphite surface. After the combination, the affinity between the graphite surface and the polytetrafluoroethylene resin is significantly improved. strengthen.

[0040] (2) Modification of graphite substrate:

[0041] Heat the graphite substrate to more than 250 degrees Celsius to completely remove the mo...

Embodiment 3

[0047] (1) Preparation of graphite material modifier:

[0048] The graphite material modifier is an aqueous solution, including 5% chromic acid, 2% phosphoric acid, 5% sodium dodecylsulfonate, 5% sodium laurate and the rest of water.

[0049] As a graphite material modifier, it has the following characteristics, which can effectively improve the composite degree between PTFE resin and graphite: chromic acid and phosphoric acid react with the graphite surface to enhance the hydrophilicity of the graphite surface. However, sodium dodecylsulfonate and sodium laurate are used as surfactants, and their hydrophilic ends are more likely to combine with the hydrophilic graphite surface. After the combination, the affinity between the graphite surface and the polytetrafluoroethylene resin is significantly improved. strengthen.

[0050] (2) Modification of graphite substrate:

[0051] Heat the graphite substrate to more than 250 degrees Celsius to completely remove the moisture and oil ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com