A kind of method for preparing magnesium boride superconducting film

A technology of superconducting thin film and magnesium boride, which is applied in the field of superconducting electronics, can solve the problems of degradation of superconducting properties of samples, instability of Mg vapor pressure, susceptibility to external pollution, etc., and achieves significant Josephson effect and long-term working characteristics Effect of stabilization, deposition process and condition simplification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

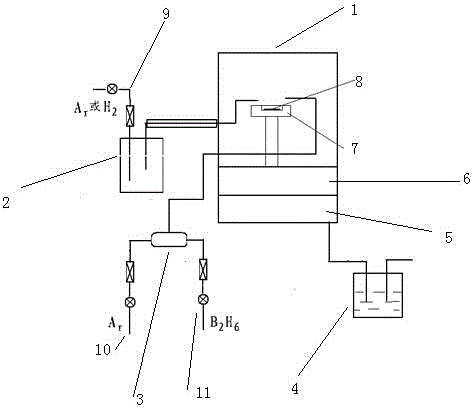

[0026] A device for preparing a magnesium boride superconducting thin film comprises a deposition chamber, a bubble meter communicates with the deposition chamber through a pipe, a gas mixing device communicates with the deposition chamber through a pipe, and the deposition chamber communicates with a waste gas treatment device.

[0027] The bubble meter is provided with a carrying gas inlet pipe, and a flow meter and a valve are installed on the carrying gas inlet pipe.

[0028] The air mixing device is provided with a first air intake pipe and a second air intake pipe, and a flow meter and a valve are installed on the first air intake pipe and the second air intake pipe.

[0029] A mechanical pump and a molecular pump are arranged at the bottom of the deposition chamber, and the mechanical pump and the molecular pump communicate with the deposition chamber.

[0030] A substrate heating device is arranged in the deposition chamber, and the substrate is placed on the substrate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com