Steam-turbine generator retaining ring ultrasonic imaging testing method

A technology of ultrasonic imaging detection and turbogenerator, which is applied in the direction of using sound wave/ultrasonic wave/infrasonic wave to analyze solids. Echo and defect echo, overcoming the complexity of detection steps, the effect of reliable non-destructive testing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

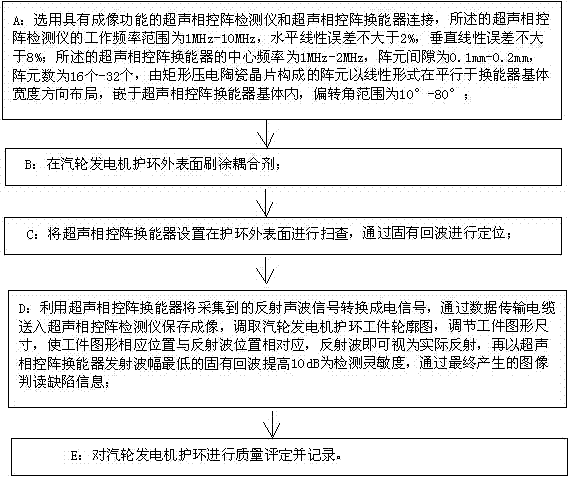

[0018] Such as figure 1 As shown, the ultrasonic imaging detection method of the turbogenerator retaining ring of the present invention comprises the following steps in turn:

[0019] A: Choose an ultrasonic phased array detector with imaging function and connect it with an ultrasonic phased array transducer. The linear error is not more than 8%; the center frequency of the ultrasonic phased array transducer is 1MHz-2MHz, the array element gap is 0.1mm-0.2mm, the number of array elements is 16-32, and it is made of rectangular piezoelectric ceramics The array elements composed of wafers are laid out in a linear form parallel to the width of the transducer substrate, embedded in the ultrasonic phased array transducer substrate, and the deflection angle ranges from 10° to 80°;

[0020] B: Brush the coupling agent on the outer surface of the turbine generator retaining ring;

[0021] C: Set the ultrasonic phased array transducer on the outer surface of the guard ring for scanni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com