Fruit and vegetable hydrogen gas high-pressure permeation and puffing method

A fruit and vegetable, hydrogen technology, applied in food preparation, food forming, food science, etc., can solve the problem of large damage to nutrients, achieve the effects of reducing nutrient loss, improving production efficiency and product quality, and reducing heat energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

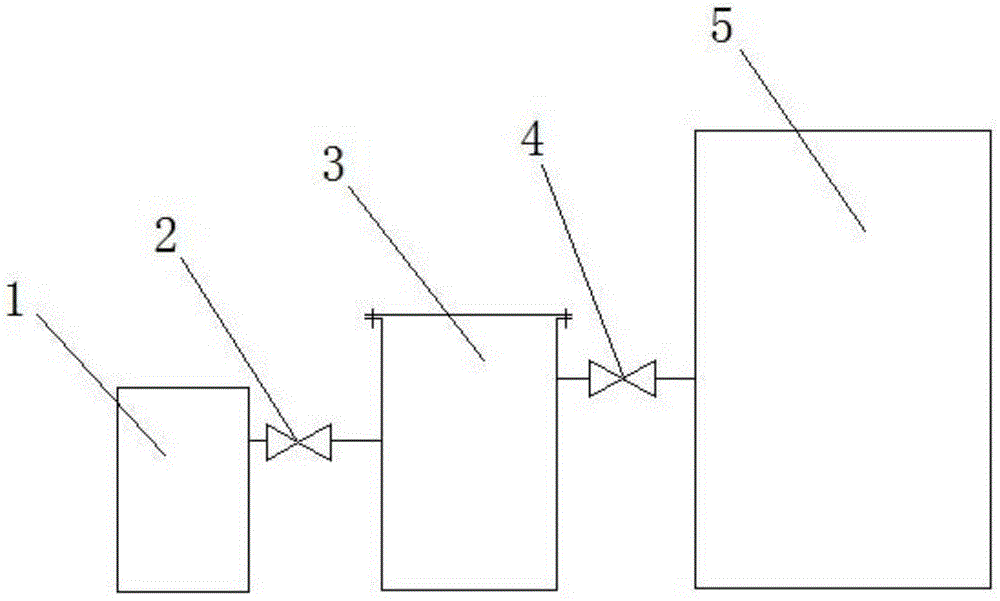

[0023] 1 kilogram of apple slices dried to a moisture content of 8% after pretreatment and a temperature higher than 30° C. is packed into an 8-liter sealed expansion tank 3 that can maintain a temperature of 35° C., and then vacuumized in the expansion tank 3 to make it The absolute pressure is less than 12KPa. Stop vacuuming and slowly fill high-pressure hydrogen into the expansion tank 3. The high-pressure gas penetrates into the inside of the raw material through the capillary pores of the raw material. The inflation time is 10 minutes, and the final inflation pressure is 0.5 MPa. Pressure balance, then connect the expansion tank with the gas recovery tank 5 which is 100 times larger than its volume, so that the pressure in the expansion tank 3 is instantly reduced to below 12KPa, and the high-pressure gas inside the apple slices or diced apples expands instantly and is absorbed by the capillary pores. The blocking effect to achieve the puffing effect.

[0024] Part of th...

Embodiment 2

[0026] 1 kg of carrot sticks dried to a water content of 10% after pretreatment and a temperature higher than 70°C is packed into an 8-liter sealed expansion tank that can maintain 80°C, and then vacuumized in the expansion tank 3 to make it absolutely The pressure is less than 12KPa. Stop vacuuming and slowly fill high-pressure hydrogen into the expansion tank 3. The high-pressure gas penetrates into the inside of the raw material through the capillary pores of the raw material. The inflation time is 60 minutes. Balance, then connect the expansion tank 3 with the gas recovery tank 5 which is 200 times larger than its volume, so that the pressure in the expansion tank 3 is instantly reduced to below 12KPa, and the high-pressure gas inside the carrot sticks or diced carrots expands instantly and is absorbed by the capillary pores. The blocking effect to achieve the puffing effect.

[0027] Part of the moisture in the carrot sticks or diced carrots is vaporized into the gas rec...

Embodiment 3

[0029] 1 kilogram of diced apples dried to a water content of 12% after pretreatment and a temperature higher than 30° C. is packed into an 8-liter sealed expansion tank 3 that can maintain 35° C., and then vacuumized in the expansion tank to make it The absolute pressure is less than 12KPa. Stop vacuuming and slowly fill high-pressure hydrogen gas into the expansion tank 3. The high-pressure gas penetrates into the inside of the raw material through the capillary pores of the raw material. The inflation time is 30 minutes, and the final inflation pressure is 1.5 MPa. Pressure balance, then connect the expansion tank with the gas recovery tank 5 which is 100 times larger than its volume, so that the pressure in the expansion tank 3 is instantly reduced to below 12KPa, and the high-pressure gas inside the apple slices or diced apples expands instantly and is absorbed by the capillary pores. The blocking effect to achieve the puffing effect.

[0030] Part of the moisture in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com