Method for manufacturing immediate dental implants with periodontal bioactivity

A technology of biological activity and manufacturing method, applied in dental implants, dentistry, dental prosthetics, etc., can solve problems such as gaps, and achieve the effect of improving the success rate, shortening the time of missing teeth, and improving the guiding activity of bone tissue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

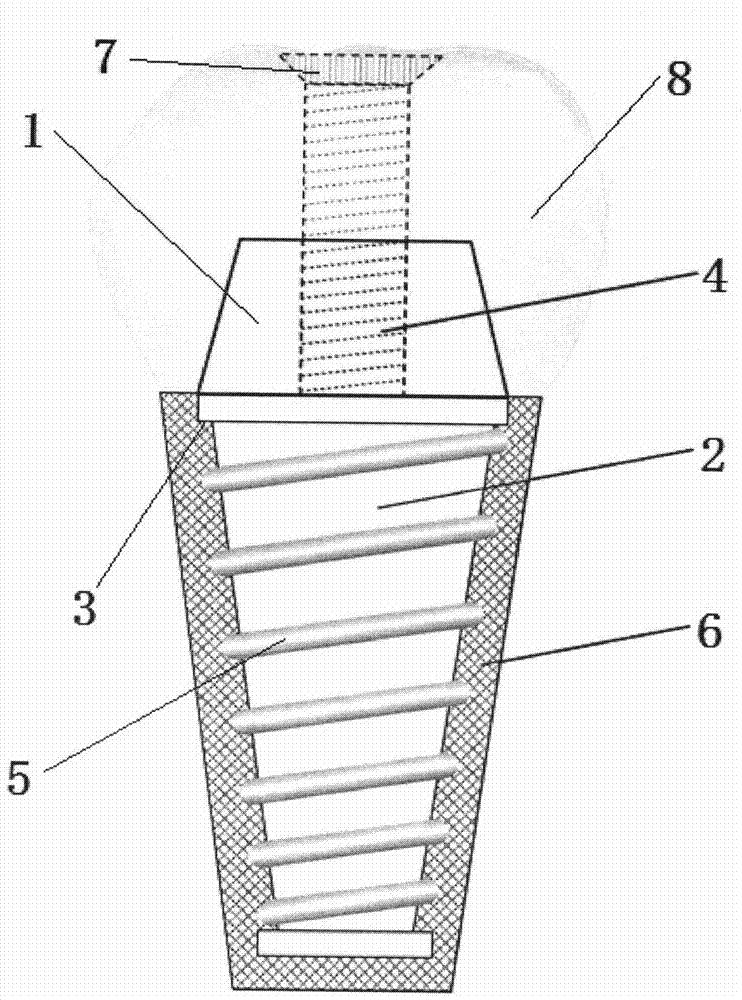

[0012] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, and the content of the specific embodiments is not intended to limit the protection scope of the present invention.

[0013] The manufacturing method of the immediate dental implant with periodontal bioactivity according to the present invention utilizes the non-coating biological modification technology combining material science and tissue engineering technology to construct the artificial tooth root with bionic cementum structure, so that the prepared implant The tooth can be implanted immediately after tooth extraction, which has some life characteristics of natural implanted teeth, greatly shortens the restoration time of missing teeth, and significantly improves the success rate of implantation.

[0014] The idea of the present invention is to use small molecule peptides to build biological activity, and use self-curing calcium phosph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com