Treatment system of waste gas generated by polyolefin wood-plastic granulation

A treatment system, polyolefin technology, applied in the direction of dispersed particle separation, chemical instruments and methods, combined devices, etc., can solve the problems of difficult production waste gas treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below with reference to specific embodiments in conjunction with the accompanying drawings, so as to better understand the present invention.

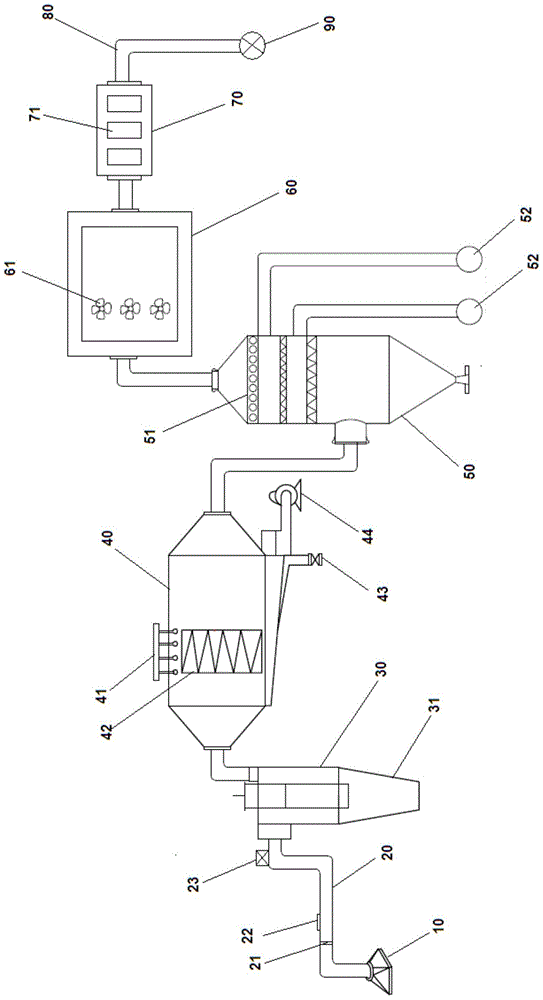

[0037] refer to figure 1 , a treatment system for waste gas produced in polyolefin wood pellets, comprising a waste gas collection device, a primary dust removal device, a spray washing device, a secondary dust removal device, a deodorization device and a fan 90 connected in sequence.

[0038] The waste gas collection device includes a dust collection hood 10 and a conveying pipe 20, one end of the conveying pipe 20 is connected to the outlet of the dust collection hood 10, and the other end is connected to the inlet of the primary dust removal device.

[0039] The dust collection hood 10 can be provided with one or more according to the air flow rate. When there are multiple dust collection hoods, branch pipelines are designed, and each branch pipeline is collected into the main pip...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com