A kind of preparation method of composite methanation catalyst

A methanation catalyst and catalyst technology, applied in the direction of producing hydrocarbons from carbon oxides, etc., can solve the problems of complex process, many influencing factors, difficult to guarantee the quality of the finished catalyst, etc., achieve good thermal stability, improve interaction force, improve Effect of crystal phase stability and thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

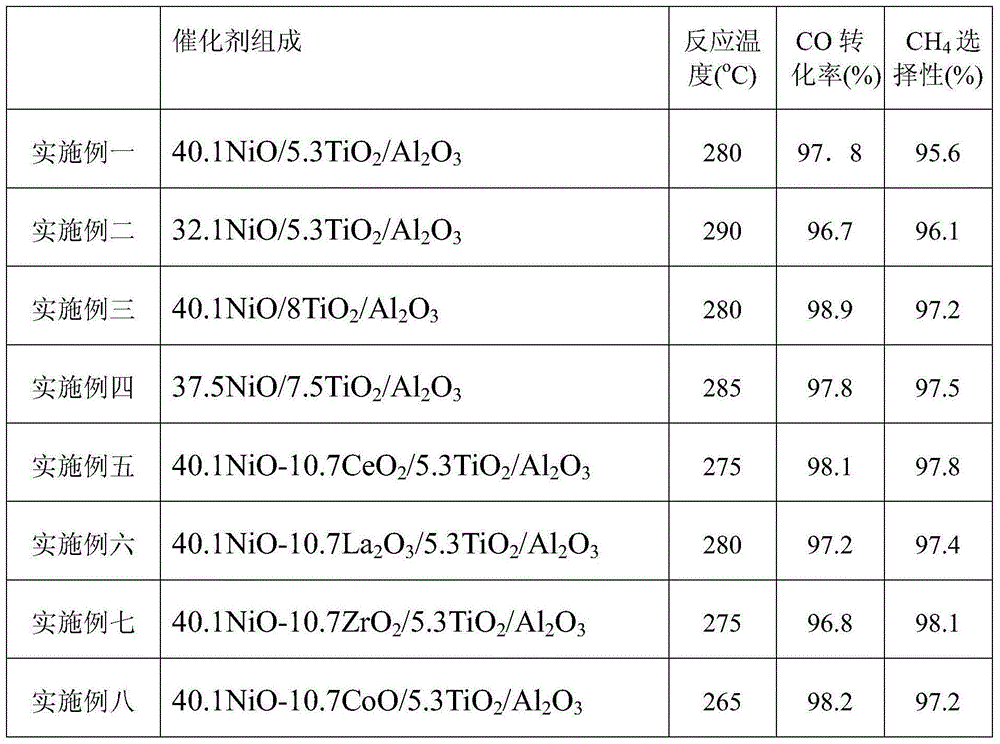

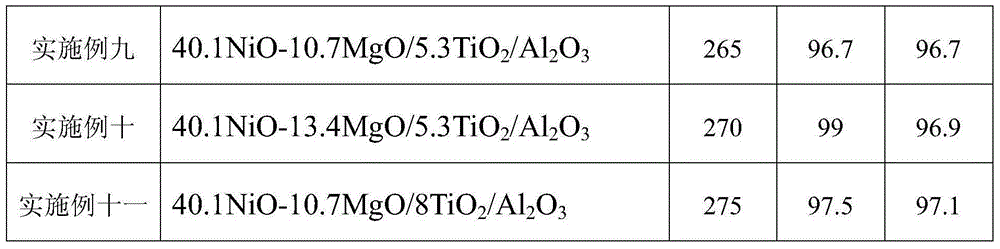

Examples

Embodiment 1

[0031] A preparation method of composite methanation catalyst, comprising the following steps:

[0032] Step 1. Weigh 20ml of tetrabutyl titanate and mix with 40ml of absolute ethanol, stir evenly to obtain tetrabutyl titanate ethanol mixed solution;

[0033] Step 2: Mix 25ml of deionized water with 25ml of absolute ethanol, add a small amount of nitric acid, and control the pH value between 3 and 4 to obtain a mixed aqueous solution of ethanol and nitric acid;

[0034] Step 3. Slowly add the ethanol nitric acid mixed aqueous solution at room temperature into the tetrabutyl titanate ethanol mixed solution dropwise using a peristaltic pump at 2 ml / min, stir vigorously at 1200 rpm to hydrolyze the tetrabutyl titanate, and continue stirring for 3 hours to obtain a sol;

[0035] Step 4. Dry the obtained sol at 80°C for 24 hours to form a gel, and place the gel in a muffle furnace for calcination at 500°C for 4 hours to obtain nano-TiO 2powder;

[0036] Step five, 1g nano-TiO 2 ...

Embodiment 2

[0041] A preparation method of composite methanation catalyst, comprising the following steps:

[0042] Step 1. Weigh 20ml of tetrabutyl titanate and mix with 45ml of absolute ethanol, stir evenly to obtain tetrabutyl titanate ethanol mixed solution;

[0043] Step 2: Mix 25ml of deionized water with 25ml of absolute ethanol, add a small amount of nitric acid, and control the pH value between 3 and 4 to obtain a mixed aqueous solution of ethanol and nitric acid;

[0044] Step 3. Slowly add the ethanol nitric acid mixed aqueous solution at room temperature into the tetrabutyl titanate ethanol mixed solution dropwise using a peristaltic pump at 2 ml / min, stir vigorously at 1200 rpm to hydrolyze the tetrabutyl titanate, and continue stirring for 3 hours to obtain a sol;

[0045] Step 4. Dry the obtained sol at 80°C for 24 hours to form a gel, and place the gel in a muffle furnace for calcination at 500°C for 4 hours to obtain nano-TiO 2 powder;

[0046] Step five, 1g nano-TiO 2...

Embodiment 3

[0051] A preparation method of composite methanation catalyst, comprising the following steps:

[0052] Step 1. Weigh 20ml of tetrabutyl titanate and mix with 40ml of absolute ethanol, stir evenly to obtain tetrabutyl titanate ethanol mixed solution;

[0053] Step 2: Mix 25ml of deionized water with 25ml of absolute ethanol, add a small amount of nitric acid, and control the pH value between 3 and 4 to obtain a mixed aqueous solution of ethanol and nitric acid;

[0054] Step 3. Slowly add the ethanol nitric acid mixed aqueous solution at room temperature into the tetrabutyl titanate ethanol mixed solution dropwise using a peristaltic pump at 2 ml / min, stir vigorously at 1200 rpm to hydrolyze the tetrabutyl titanate, and continue stirring for 3 hours to obtain a sol;

[0055] Step 4. Dry the obtained sol at 80°C for 24 hours to form a gel, and place the gel in a muffle furnace for calcination at 500°C for 4 hours to obtain nano-TiO 2 powder;

[0056] Step five, 1.5g nanometer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com