Surface modification method of magnetic microspheres

A technology of surface modification and magnetic microspheres, which is applied in the field of polymer materials, can solve problems such as difficult uniformity and controllable surfaces, and achieve the effect of high uniformity and low leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Weigh 1 g (15 μm) of polyethyleneimine-modified magnetic microspheres and disperse them in 200 g of deionized water, add 1 g of glycidyl methacrylate, 2 g of 1,4-butanediol diglycidyl ether, ethylene glycol di 1 g of methacrylate was reacted at 80° C. for 10 h, 40 g of sodium persulfate aqueous solution (1%) was added dropwise, and the reaction was continued for 12 h after the addition was completed. Washing with absolute ethanol and deionized water in sequence to obtain magnetic microspheres modified with epoxy groups on the surface.

Embodiment 2

[0032] Weigh 1g (25um) of polyethyleneimine-modified magnetic microspheres and disperse them in 200g of deionized water, add 1g of allyl glycidyl ether, 1.5g of ethylene glycol diglycidyl ether, ethylene glycol dimethacrylic acid 1g of ester was reacted at 70°C for 12h, 40g of sodium persulfate aqueous solution (1%) was added dropwise, and the reaction was continued for 10h after the addition was completed. Washing with absolute ethanol and deionized water in sequence to obtain magnetic microspheres modified with epoxy groups on the surface.

Embodiment 3

[0034] Weigh 1 g of the surface epoxy group-modified magnetic microspheres prepared in Example 2 and disperse them in 200 g of 0.1 M NaOH aqueous solution, stir at 75 ° C for 4 h, wash with deionized water until the supernatant is neutral, and dry to obtain magnetic microspheres. ball powder. Take 0.5g of the above magnetic microsphere powder and ultrasonically disperse it in 100g of N,N-dimethylformamide, add 0.1g of pyridine and 1g of succinic anhydride, stir at room temperature for 6h, and wash with absolute ethanol, 0.1M NaOH, and deionized water successively. Wash until the supernatant is neutral to obtain magnetic microspheres with carboxyl groups on the surface.

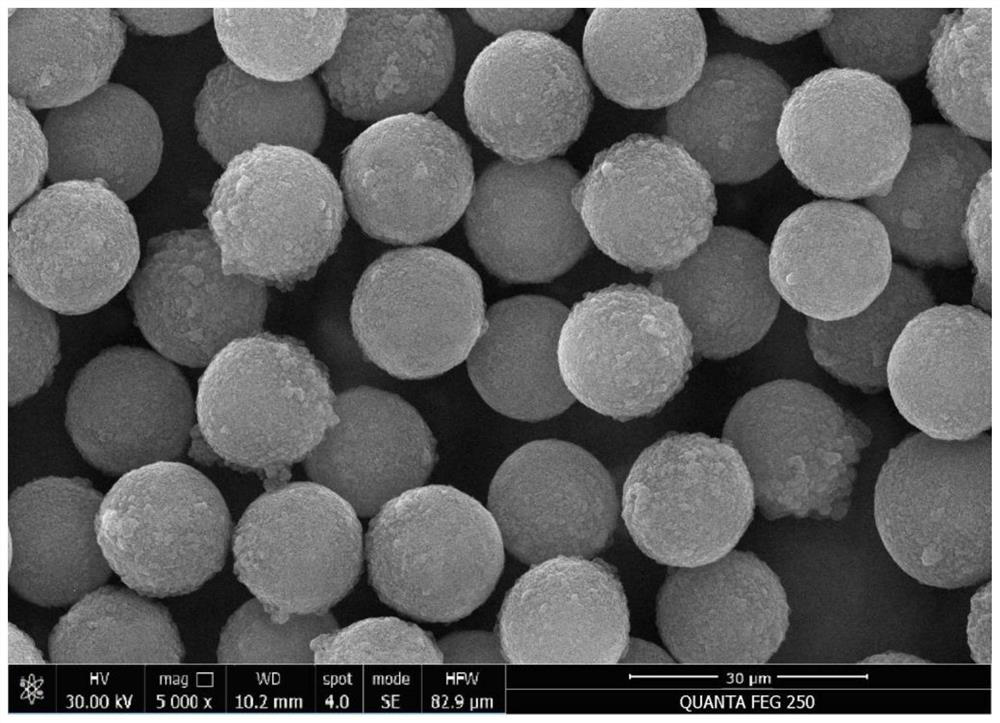

[0035] Depend on figure 1 It can be seen that the surface of the magnetic microspheres prepared in Example 1 is uniform and there is no aggregation of magnetic particles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com