Organic fertilizer fermentation device and using method thereof

A fermentation device and organic fertilizer technology, applied in the field of organic fertilizer fermentation devices, can solve problems such as inability to infiltrate feces, inability to absorb oxygen, and insufficient contact with feces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

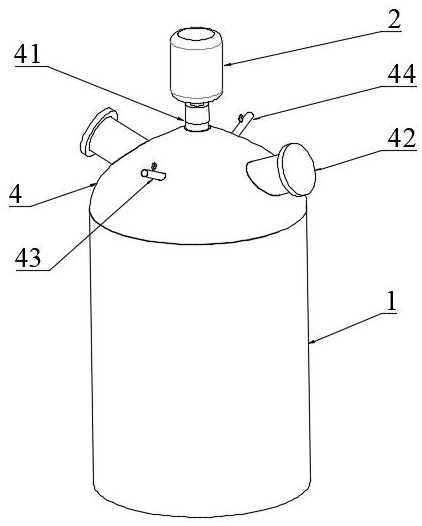

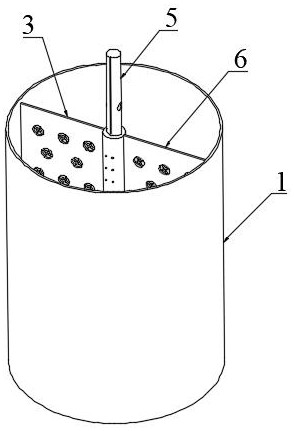

[0051] Such as figure 1 , Figure 7 As shown, this embodiment provides an organic fertilizer fermentation device, including a fermentation shell 1 , a rotating structure 2 , and a stirring structure 3 .

[0052] Specifically, the top of the fermentation shell 1 is provided with a feed structure 4, and the top of the feed structure 4 is provided with a through hole 41. The feed structure 4 includes two manure inlets 42, a water pipe 43, an oxygen pipe 44, and two manure inlets. 42 are arranged symmetrically, and the fermenting shell 1 is used to accommodate feces and ingredients required for fermenting feces.

[0053] Specifically, the rotating structure 2 is arranged above the feeding structure 4, and the rotating structure 2 includes a rotating motor 21, and the rotating motor 21 is arranged on a support frame. The support frame in this embodiment belongs to a conventional structure, and will not be described in detail here.

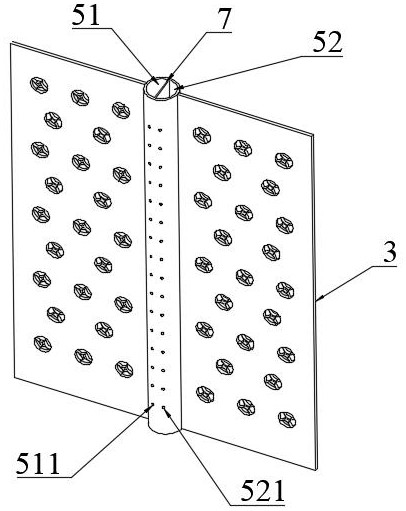

[0054] Specifically, such as image 3 As shown...

Embodiment 2

[0061] Such as Figure 8 As shown, another organic fertilizer fermentation device provided in Example 2 has basically the same structure as that in Example 1, and the similarities will not be described again. The difference is that it also includes a control system.

[0062] The control system includes a water content sensor, an oxygen content sensor, a temperature controller, and a PLC. The water content sensor is located in the water pipe 43 for monitoring the water content in the fermentation shell 1 and sending the water content value to the PLC; the oxygen content sensor is located in the The oxygen pipe 44 is used to monitor the oxygen content in the fermentation shell 1 and send the oxygen content value to the PLC; the temperature controller is arranged on the side wall of the feed structure 4 and is used to monitor the temperature in the fermentation shell 1 and send the temperature value to the PLC. Send to PLC; PLC is used to receive water content value, oxygen conte...

Embodiment 3

[0064] Such as Figure 9 As shown, the present embodiment provides a method for using an organic fertilizer fermentation device. The organic fertilizer fermentation device described in Example 1 is used to ferment poultry manure. The specific method for using the fermentation device includes the following steps:

[0065] Feeding stage: feed poultry manure and ingredients into the fermentation shell 1 from the manure inlet 42 according to a certain ratio, and the input amount of poultry manure and ingredients cannot exceed the height of the stirring blade 6, wherein the ingredients include one or more of plant roots, stems and leaves. various;

[0066] Water injection stage: turn on the control switch of the water pump, and inject the water of preset volume into the water chamber 51 through the water pipe 43; The two stirring blades 6 rotate, and the rotating motor 21 stops after rotating the preset number of turns;

[0067] Oxygen injection stage: turn on the control switch ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com