Stone crushing hammer for stone crusher

A stone crushing hammer and stone crusher technology, which is applied in grain processing and other directions, can solve the problems of fast wear, lower strength of stone crushing hammer, and lower stone crushing effect of stone crusher.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in further detail below by means of specific embodiments:

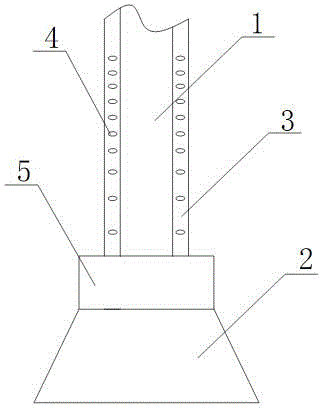

[0012] The reference signs in the accompanying drawings of the specification include hammer handle 1 , hammer head 2 , chute 3 , protruding teeth 4 , and buffer block 5 .

[0013] The crushing hammer of the embodiment is as attached figure 1 Shown: It includes hammer handle 1 and hammer head 2. The hammer head 2 is in the shape of a truncated cone. The hammer handle is vertically installed at the center of the upper part of the hammer head 2. Add reinforcement plates around, hammer handle 1 is provided with buffer block 5, the material of buffer block 5 is cast iron or other materials that are harder and denser and the material with lower cost, the shape of buffer block 5 becomes cylindrical, with The cost of the buffer block 5 is lower, and the cylindrical structure is more convenient to process and the force effect is better. The cross section of the hammer handle 1 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com