Magnetic impurity filtering system used for producing lithium battery material

A technology of magnetic impurity and filtration system, applied in the fields of magnetic separation, solid separation, chemical instruments and methods, etc., can solve the problems of reducing the specific capacity and energy density of lithium battery materials, large content of magnetic impurities, and improving the self-discharge rate of finished batteries.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

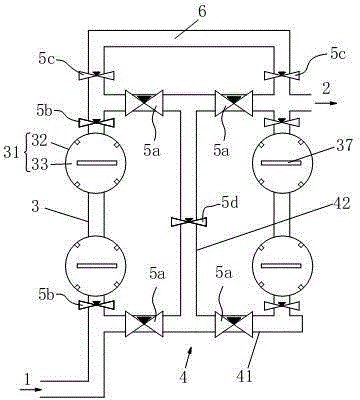

[0023] Such as figure 1 As shown, a magnetic impurity filtration system for the production of lithium battery materials described in the first embodiment of the present invention includes a feed port 1 and a discharge port 2, and a Two groups of filter tubes 3 are connected by a reversing pipeline 4 in the shape of "I" between adjacent filter tubes 3, and valves 5a are respectively provided on the four branch pipes 41 of the reversing pipeline 4; the two ends of the filter tubes 3 Valves 5b are respectively provided, and each set of filter tubes 3 includes at least one magnetic filter device 31 . The setting of the magnetic filter device can effectively filter the magnetic impurities in the slurry. The setting of multiple sets of filter tubes ensures a more thorough filtering effect. At the same time, considering that the magnetic filter device needs to be cleaned and replaced regularly, the reversing pipeline and the corresponding valve settings , to achieve flexible control...

Embodiment 2

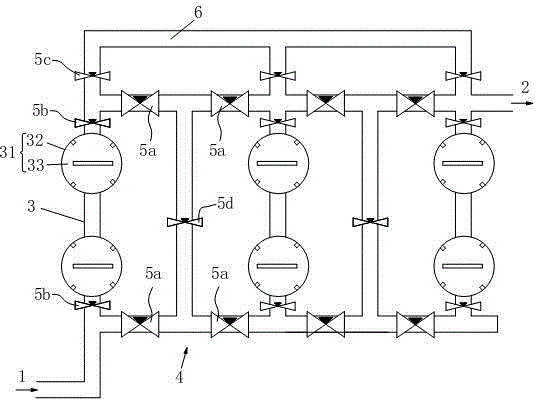

[0035] Such as figure 2 As shown, the difference between the second embodiment and the first embodiment is that three sets of filter tubes 3 are arranged between the feed port 1 and the discharge port 2 . The working principle is the same as that of the first embodiment, only the change in the number of reversing pipelines to be operated will not be repeated.

Embodiment 3

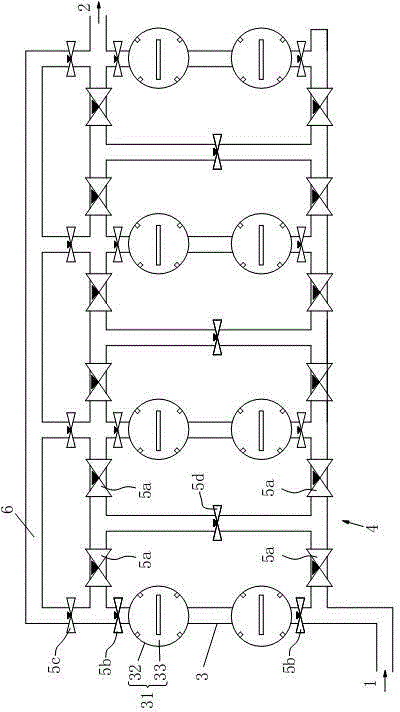

[0037] Such as image 3 As shown, the difference between the third embodiment and the first two embodiments is that four sets of filter tubes 3 are arranged between the feed port 1 and the discharge port 2 . The working principle is the same as that of the first embodiment, only the change in the number of reversing pipelines to be operated will not be repeated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com