Straight wire drawing machine without tuning roller, electrical system and tension calculation method

A technology of electrical system and calculation method, which is applied in the field of straight wire drawing machine, can solve the problems of high maintenance cost, signal attenuation and interference of displacement sensor and potentiometer, and achieve the effect of meeting production needs, low use cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

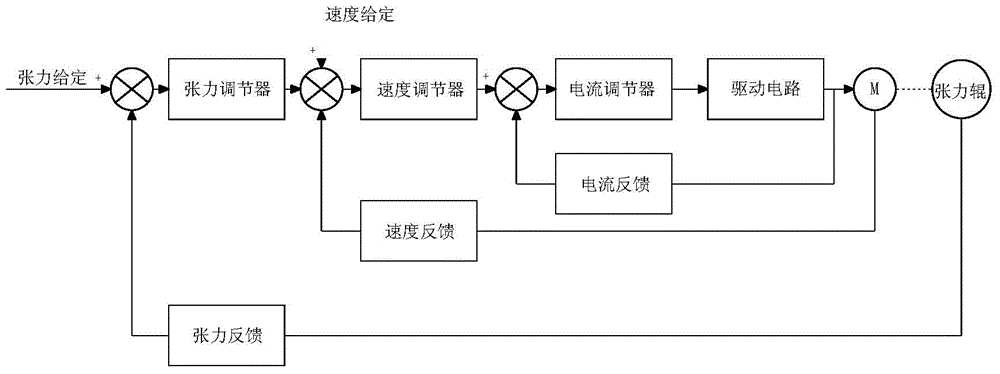

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

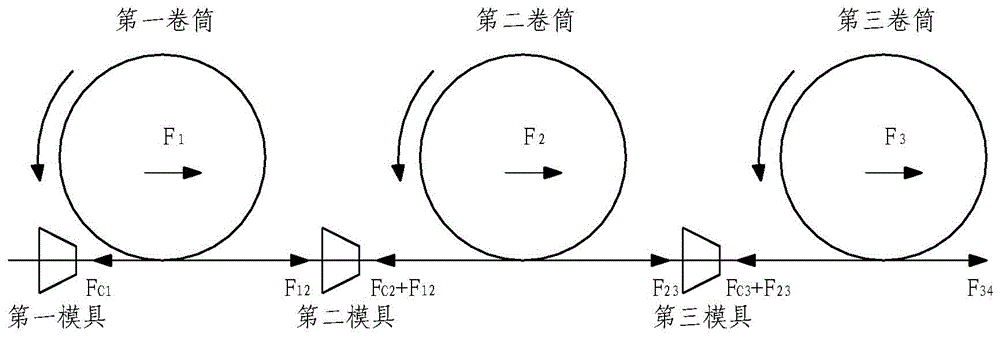

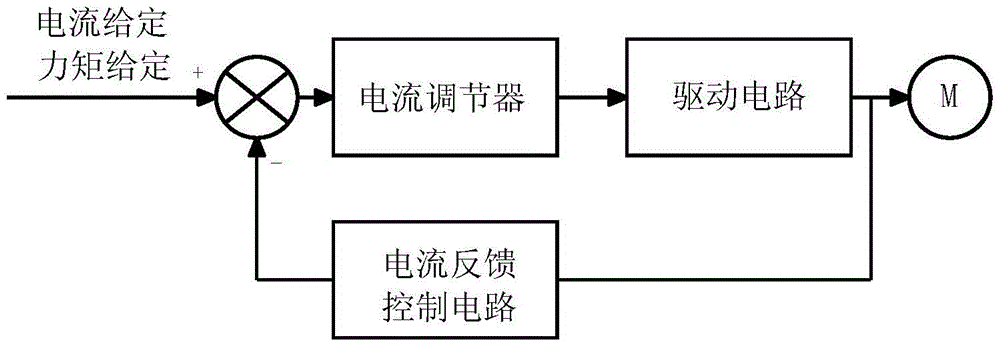

[0032] In the embodiment of the present invention, the tension calculation method for a straight wire drawing machine without tuning rollers comprises the following steps:

[0033] S1: preset the operating current I of the reel motor 1 .

[0034] S2: According to the formula Calculate the output torque of the reel motor, T in the formula e is the output torque of the reel motor, K is a constant, I 0 Is the no-load current of the reel motor, I 1 is the operating current of the reel motor.

[0035] K=3N r u 1 / W 1 , where N r is the number of pole pairs of the reel motor, U 1 is the stator phase voltage, W 1 is the supply angular frequency.

[0036] S3: according to formula F 拉 =T e I / R calculates the pulling force of the reel motor on the steel wire, F in the formula 拉 I is the pulling force of the reel motor on the steel wire, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com