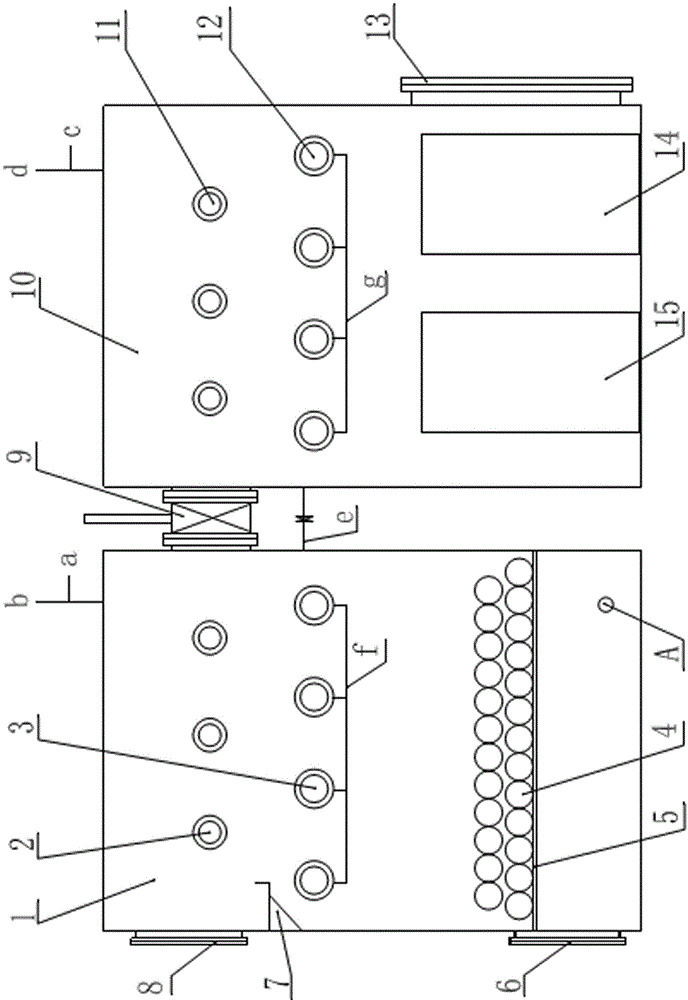

Battery grade lithium metal glove box with fully enclosed metal structure

A metal structure, fully enclosed technology, applied in the field of metal lithium glove box equipment, can solve the problems of difficult to find leakage, entry of outside natural air, long time, etc., to achieve the effect of safe sealing performance, small space, and simple equipment structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0038] 1) When the glove box is filled with argon and circulated, put on the long-arm gloves of the demoulding box, take out the mold containing the solidified lithium metal through the material channel 8 and place it on the lithium ingot demoulding frame 7, after the mold is automatically turned over , the lithium ingot is separated from the mold, and the demolded lithium ingot 4 is temporarily stored on the argon gas distribution plate 5 in the demoulding box 1 and continues to cool to normal temperature.

[0039] 2) Open the connecting pipe e valve between the demoulding box 1 and the packaging box 10, and open the vacuum gate valve 9 between the demoulding box 1 and the packaging box 10 after the pressure on both sides is balanced.

[0040] 3) Put on the long-arm gloves of the packaging box 10, and transfer the cooled lithium ingots 4 to the packaging box 10 through the vacuum gate valve 9, and store them in the turnover barrel 14 after being packaged by the packaging machi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com