Novel mechanical locking drill rod three-part guide plate and production method thereof

A manufacturing method and technology of guide plates, which are applied in the direction of manufacturing tools, drilling/drilling equipment, parts of boring machines/drilling machines, etc., can solve the problems of poor high-temperature bearing capacity of guide plates, falling off, complicated processing, etc., to avoid guiding Plate breakage, prolonging the service life, and increasing the welding area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

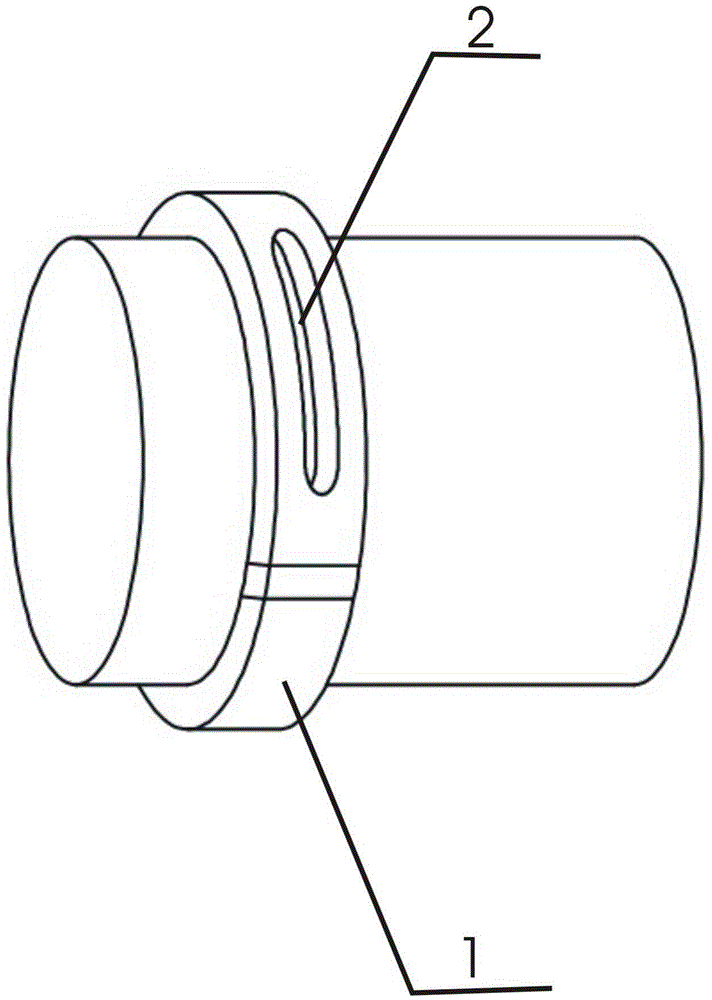

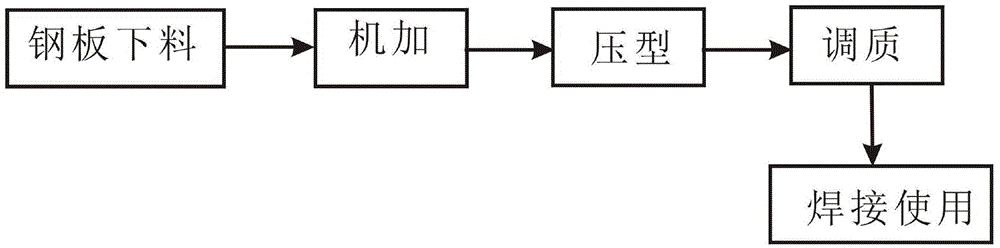

[0016] The guide plate is welded by three splicing blocks 1, and the middle part of the guide plate is provided with a 40-50mm water tank 2, and the splicing block 1 is made of steel plate. The specific manufacturing steps are as follows: first select the material, cut three splicing blocks 1 on the steel plate; then perform mechanical processing on the splicing block 1, accurately remove the excess material of the splicing block 1 through the processing machine, and set up a water tank 2; and then splice Block 1 is molded so that the three splicing blocks 1 are spliced together to form a ring; then the splicing block 1 is subjected to quenching and tempering treatment, that is, a comprehensive heat treatment process of quenching and high-temperature tempering; finally, the welding operation is performed, and the three splicing blocks 1 Welded into a ring to form the guide plate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com