Waste GMT material recycling granulation method for vehicle and special device thereof

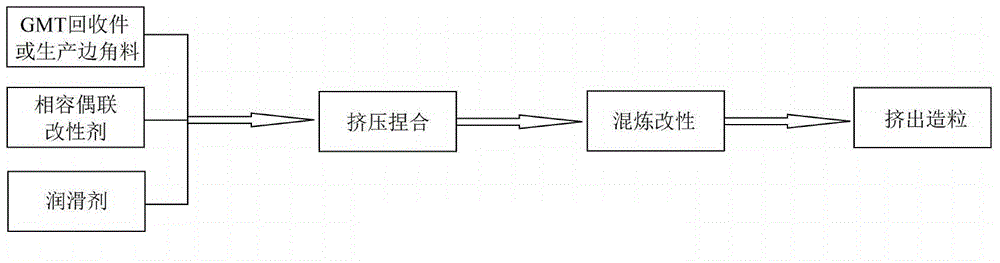

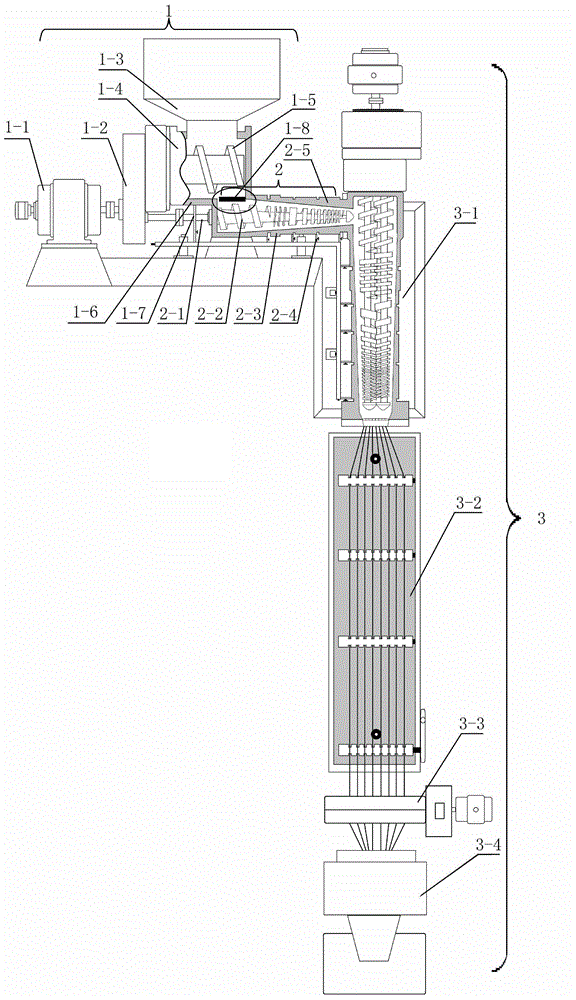

A material recovery and special device technology, which is applied in the field of continuous mixing, extrusion and granulation devices, can solve the problems of reducing production costs and the inability of internal mixers and extruders to form continuous processing and production, so as to reduce production costs and improve Modified uniformity and mechanical properties, flexible and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

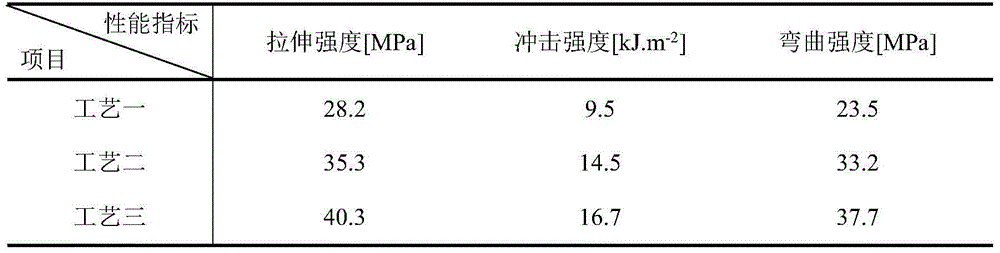

Embodiment 1

[0046] Example 1. In the example of the present invention, GMT punching scraps (glass fiber felt-reinforced polypropylene-based composite material, component GF / PP) are taken from the ceiling of the automobile interior decoration, wherein the content of glass fiber is 40wt%. First add the GMT punching scraps to the feeding device, and at the same time add modifiers with compatibility and coupling properties, maleic anhydride grafted polypropylene PP-g-MAH, acrylic acid grafted polypropylene (PP-g-AA ), silane coupling agent KH-550 and ethylene bis stearyl EBS lubricant. When adding modifiers, the weight ratio of waste GMT leftovers to each modifier is 100:5:5:3:4. The material in the above-mentioned feeding device is forced to be fed into the banburying and melting chamber under the screw extrusion of a pair of multi-edged helical rotors. The temperature of the banburying and melting chamber is controlled at 200°C. The input heat and the shearing, crushing, extrusion and knea...

Embodiment 2

[0054] Embodiment 2, in the embodiment of the present invention, get the automobile wheel cover GMT punching scrap (glass fiber mat reinforced polyethylene terephthalate / polypropylene-based composite material, composition GF / PP / PET), wherein the glass fiber The content is 30 wt%, and the content of polypropylene is 20 wt%. First add the GMT punching scraps to the feeding device, and at the same time add modifiers with compatibility and coupling properties, maleic anhydride grafted polypropylene PP-g-MAH, acrylic acid grafted polypropylene (PP-g-AA ), silane coupling agent KH-550 and ethylene bis stearyl EBS lubricant. When adding modifiers, the weight ratio of waste GMT leftovers to each modifier is 100:5:5:3:4. The material in the above-mentioned feeding device is forced to be fed into the mixing and melting chamber under the screw extrusion of a pair of multi-edged helical rotors. The temperature of the banburying and melting room is controlled at 260°C. The input heat and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com