Rail vehicle mid-roof modular structure and rail vehicle

A rail vehicle and car roof technology, applied in the field of rail vehicles, can solve the problems of insufficient space to arrange air-conditioning air ducts, fail to meet the vehicle height limit requirements, and fail to meet the weight reduction of the car body, so as to improve the poor air-conditioning effect, Improve the construction process, the overall beautiful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

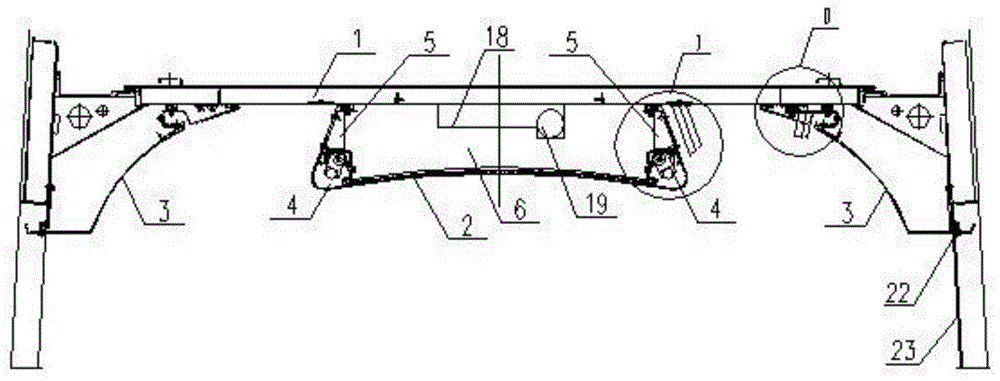

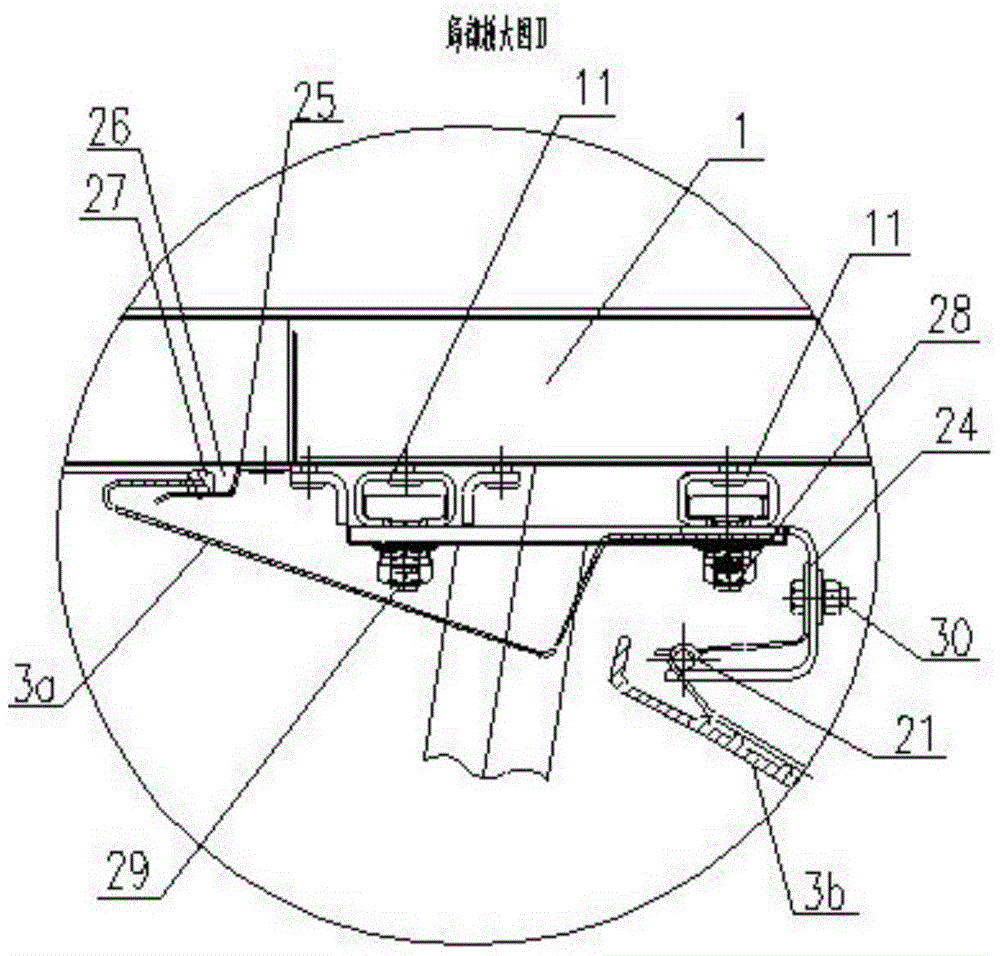

[0031] Such as figure 1 As shown, the present invention provides a rail vehicle, including a car body, a roof-mounted air-conditioning unit, a waste discharge device, etc., and the roof-mounted air-conditioning unit is fixedly installed on the roof steel structure 1 at the top of the car body. An interior trim panel is installed on the inner side of the car body to beautify the riding environment in the passenger compartment. The interior trim panel includes a side wall panel 23, a middle roof panel 2 in the middle of the roof, side roof panels 3 on both sides of the roof, end wall panels and Floor, wherein side top board 3 is two, is installed in the both sides of middle top board 2. In this embodiment, the middle roof plate 2 is fixedly installed on the roof steel structure 1 as a whole as a modular structure.

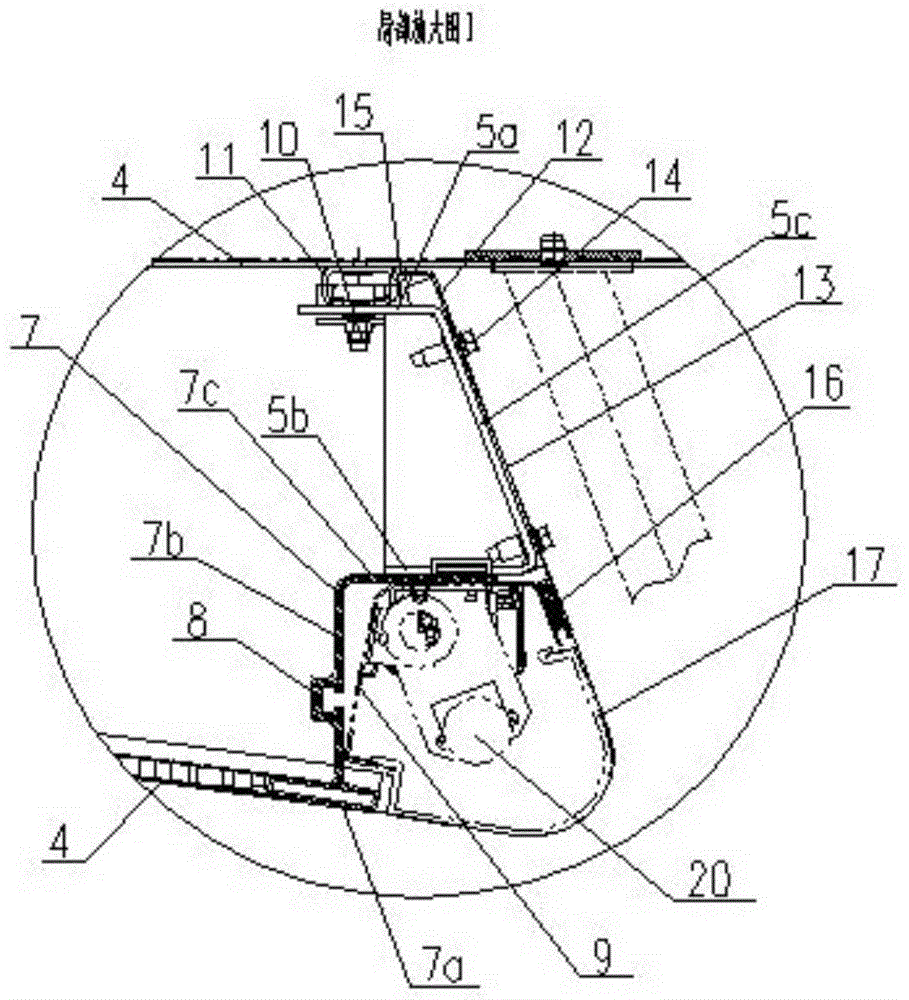

[0032] Such as figure 1 and figure 2 As shown, the middle roof modular structure provided by the present invention includes a middle roof 2 in the middle of the ...

Embodiment 2

[0050] The difference from Embodiment 1 is that according to the requirements of the passenger room, no side roof 3 is provided in the passenger room, and the middle roof structure is directly used to realize functions such as air supply, return air, and lighting, and the air treated by the air conditioning unit enters the air supply After the air duct 6, it flows out from the air supply port 13 in the car on the side air supply plate 12 on both sides, and enters the space on the side roof of the vehicle, and cold air is sent into the passenger room by natural convection to regulate the ambient temperature and humidity in the passenger room.

Embodiment 3

[0052] The difference from the above embodiment is that, in addition to setting the side roof air outlets 21 and 22 on the side roof 3, the interior air outlets (not shown) can also be set on the middle roof 2 according to actual needs. The air supply port in the car on 2 can be made up of a plurality of small round through holes, also can be the slit shape opening.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com