Powder packaging line rapid and accurate feeding and weighing method and device

A packaging line and material weighing technology, which is applied in the direction of packaging, transportation and packaging, and the type of packaged items, can solve the problem of increasing the complexity of the system structure, the packaging line is not suitable for automatic weighing packaging of fine air-entrained powder materials, and the transfer of packaging material bags Increase difficulty and other issues to achieve fast and high-precision feeding and weighing, improve efficiency, and improve feeding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

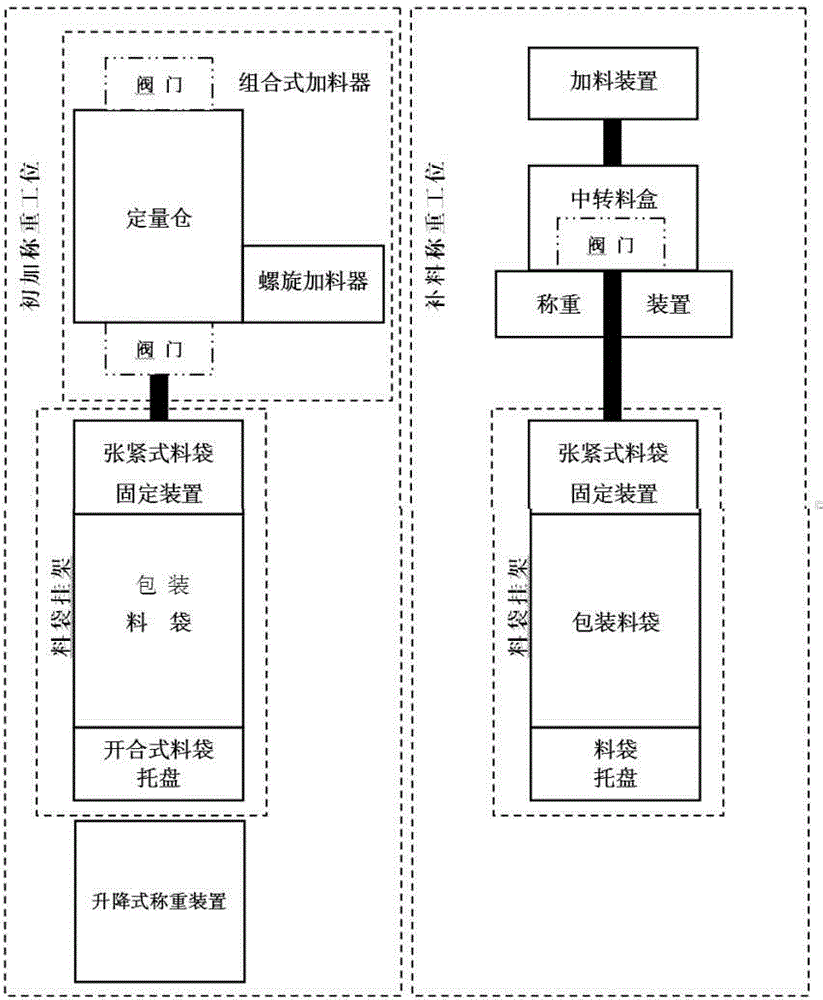

[0066] The structural frame diagram of the initial feeding weighing station and the replenishing weighing station related to the method and device provided by the present invention in the first embodiment is as follows: figure 2 Shown.

[0067] Initial feeding and weighing station:

[0068] The initial feeding and weighing station is composed of a combined feeder arranged above and a weighing device arranged below the station. With the cooperation of the adjustable partition, the cavity volume of the combined feeder can be adjusted between 45-50 liters. The volume of the cavity is adjusted according to the maximum specific gravity that may occur on the production line, so that it can accommodate the maximum specific gravity. The powder weight does not exceed the nominal weight of 50 kg; the diameter of the screw feeder is 240mm, the maximum feeding speed is 5 liters / sec; the weighing device is composed of 3 SWB8 load cells with a rated capacity of 50 kg, and 3 weighing The sensor...

Embodiment 2

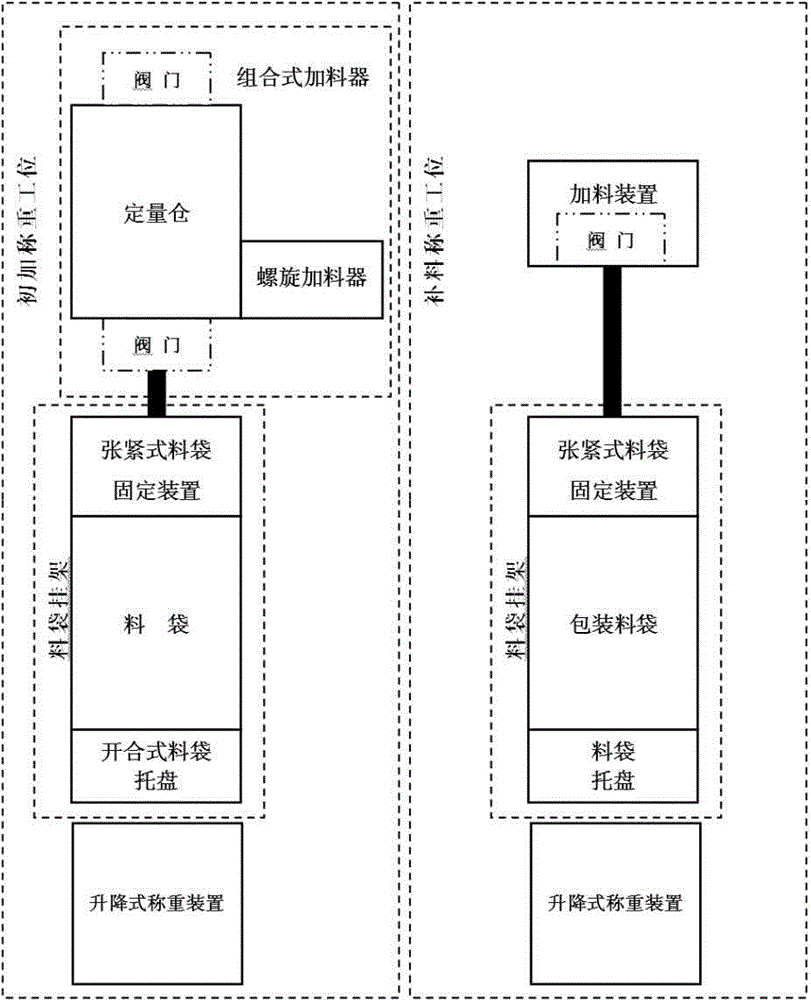

[0075] In the second embodiment, the structural frame diagram of the initial feeding weighing station and the replenishing weighing station related to the method and device provided by the present invention are as follows: image 3 Shown.

[0076] The initial feeding station of the second embodiment is exactly the same as that of the first embodiment; except that the feeding device is different from the initial feeding station, the rest of the replenishing station is also exactly the same as the initial feeding station.

[0077] The replenishing weighing station of the second embodiment uses the same rotary grid feeder as the first embodiment to directly replenish the packaging material bag that has completed the initial feeding and weighing step. The weighing system with the same weight measures the replenishment process. Since the replenishment weighing work in the second embodiment is directly performed on the packaging material bag that has completed the initial feeding and wei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com