Sulfur recycling process for circularly treating low-concentration acidy gas by utilizing liquid sulfur

A cyclic treatment and sulfur recovery technology, applied in the preparation/purification of sulfur, sulfur compounds, inorganic chemistry, etc., to achieve the effect of high exhaust gas purification rate and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

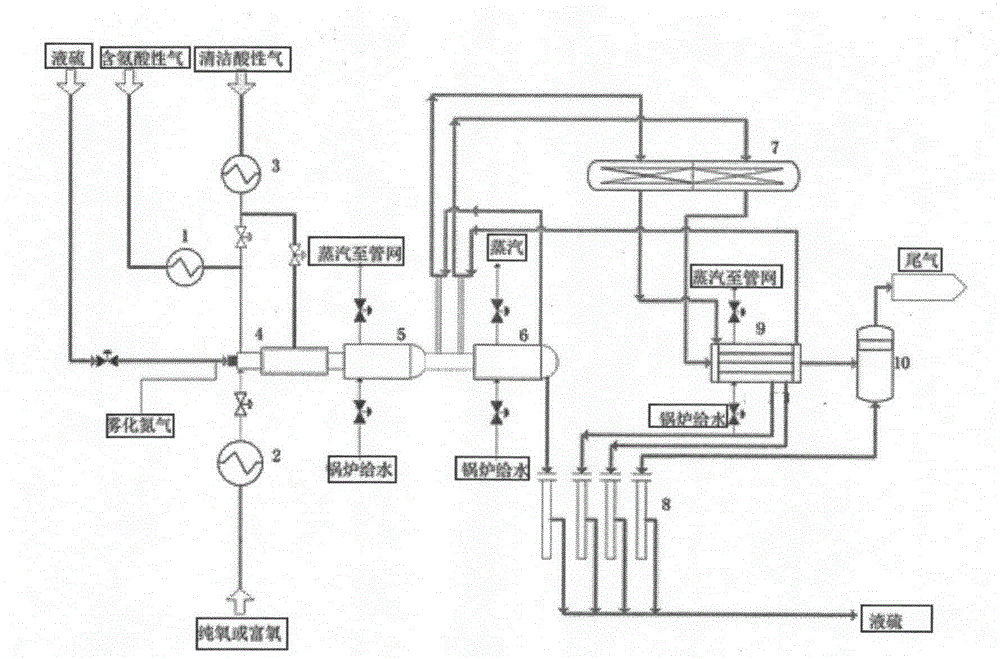

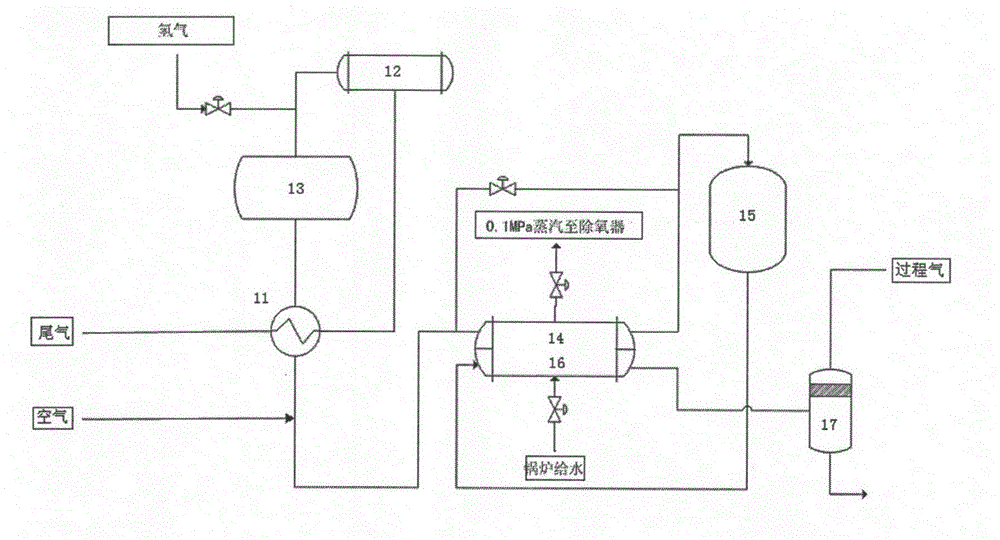

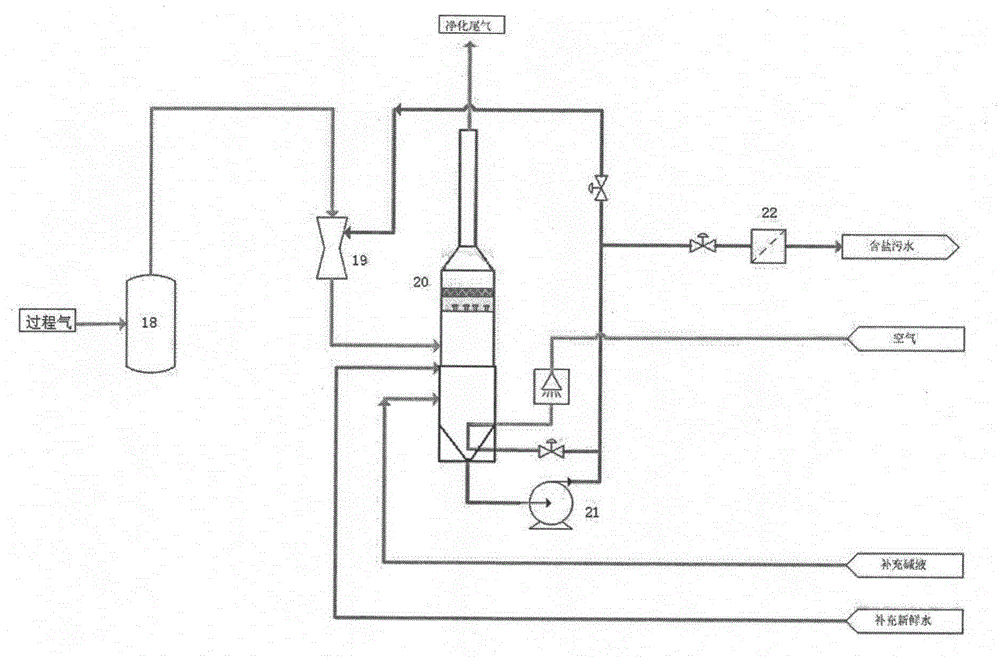

[0022] A sulfur recovery process for liquid sulfur recycling to treat low-concentration acid gas, which uses H 2 The volume concentration of S is 5% acid gas and H produced by coal chemical process 2 The acid gas with a volume concentration of S of 15% and an ammonia volume concentration of 18% is subjected to Claus combustion, and the process gas generated by combustion is subjected to a two-stage Claus reaction, and the tail gas produced by the two-stage Claus reaction is Hydrogenation-direct oxidation and wet scrubbing are carried out sequentially to recover sulfur produced in the process of Claus combustion, two-stage Claus reaction and hydrogenation-direct oxidation, as follows:

[0023] The first step: Claus combustion: The difference from conventional Claus combustion is that the liquid sulfur is transported from the liquid sulfur pool to the burner inlet of the sulfur reactor through the liquid sulfur pump, and the liquid sulfur is atomized with nitrogen at the same te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com