Anaerobic digestion tank and assembly method thereof

An anaerobic digestion tank and tank body technology, applied in biochemical equipment and methods, biochemical cleaning devices, biochemical instruments, etc., can solve the problems of long construction period, high cost, poor structural strength, etc., to shorten the construction period, The effect of increased service life and high structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

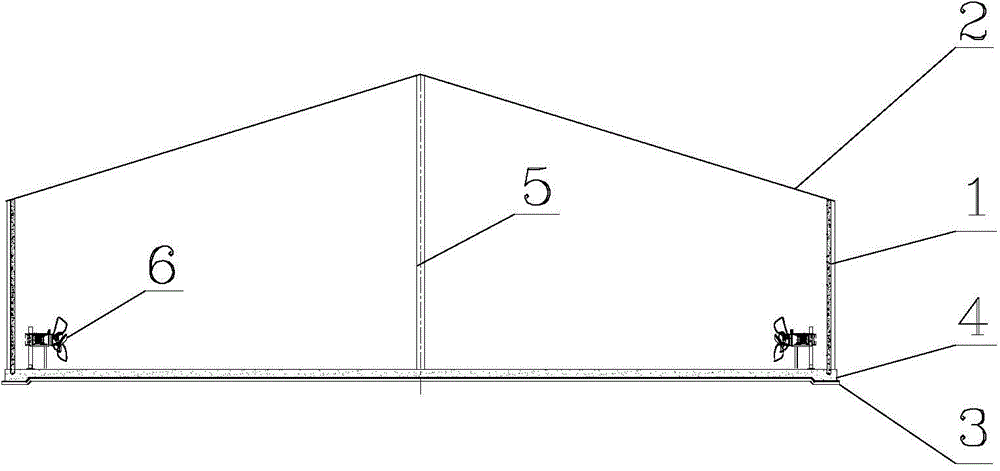

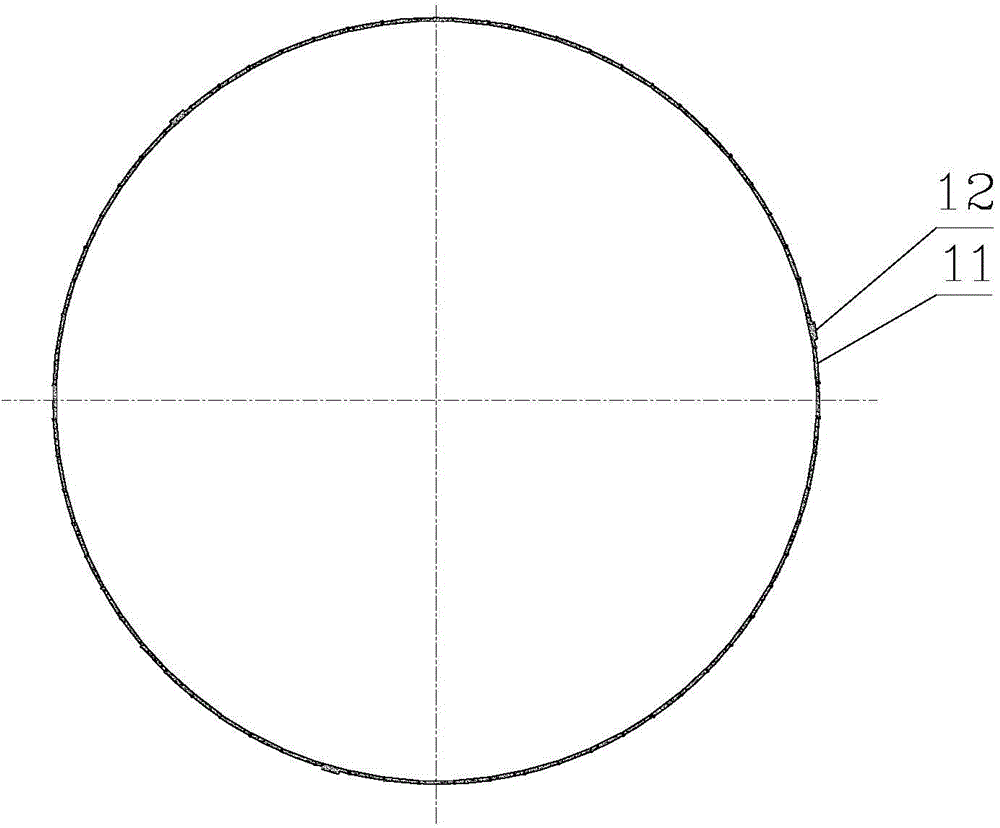

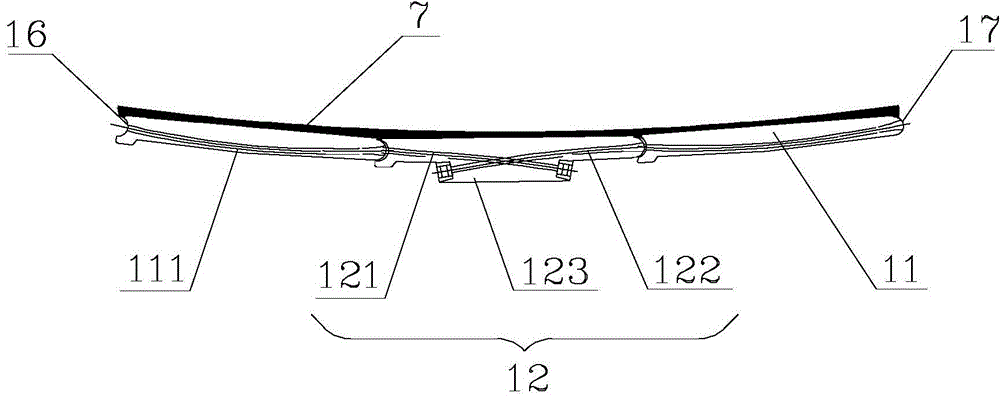

[0030] see figure 1 As shown, an anaerobic digestion tank includes a double-membrane flexible gas storage roof 2 and a tank body assembled from prefabricated parts plates 1, and the double-membrane flexible gas storage roof 2 is installed on the top of the tank body; A central column 5 is provided at the center of the bottom, and the center of the double-membrane flexible gas storage ceiling 2 is supported by the central column 5; submersible mixers 6 are respectively provided at both sides of the bottom of the tank. The double-membrane flexible gas storage ceiling 2 is a two-layer membrane structure, in which the inner layer is a gas storage membrane, and the outer layer is a protective film, and the gas storage membrane and the protective membrane are compressed and connected by a lower flange with a socket structure ; The edge of the prote...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com