High-performance fiber grid anchorage system and method

A high-performance fiber and grid technology, applied in building maintenance, structural elements, building components, etc., can solve the problems of FRP grid use effect discount, weak bonding point, poor bonding effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

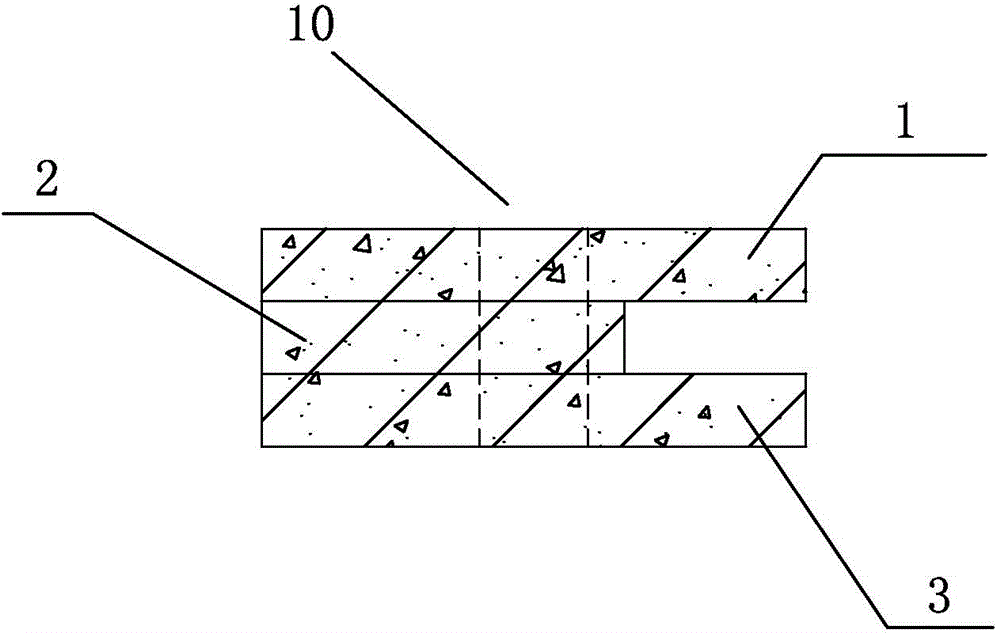

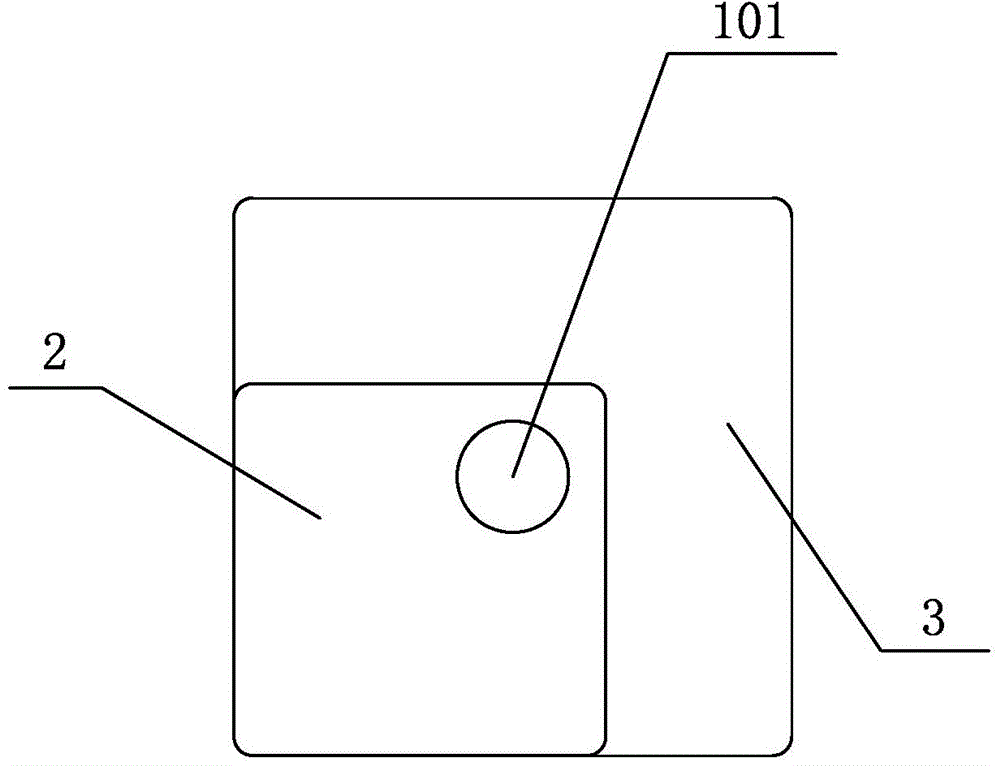

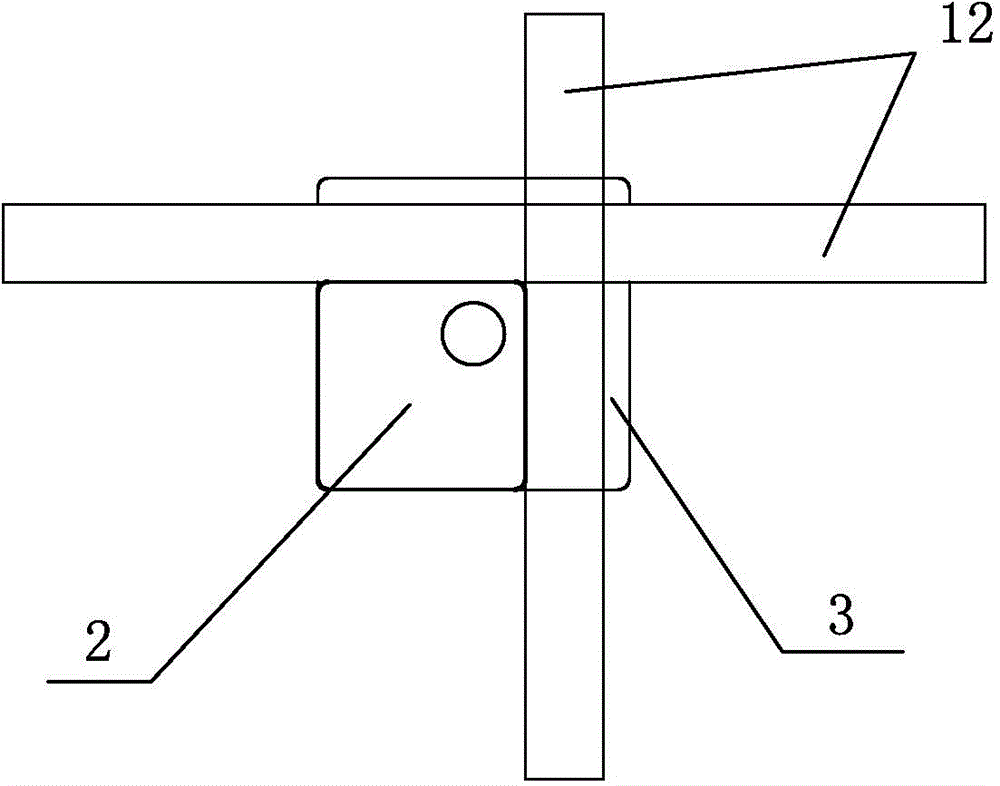

[0026] like figure 1 , figure 2 As shown, a high-performance fiber mesh anchoring system of the present invention includes an anchor 10 made of a prefabricated PVA-ECC material. The PVA-ECC material has good mechanical properties, especially toughness and impact resistance. In the process, the anchoring effect can be played continuously without damage, and PVA-ECC, as a cement-based material, has good adhesion with the concrete matrix, and it is not easy to form weak points of adhesion. The anchor 10 includes an upper pressing piece 1, a middle fixing piece 2, and a bottom gasket 3 glued together by structural glue from top to bottom, the left side surfaces of the upper pressing piece 1, the middle fixing piece 2, and the bottom gasket 3, The front surfaces are respectively aligned, so that the left sides of the upper pressing piece 1, the middle fixing piece 2, and the bottom gasket 3 are located in the same plane, and the front surfaces of the upper pressing piece 1, the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com